1. Introduction

Just this week, a major architecture firm unveiled a new eco-friendly office complex in Portland featuring a striking corten steel facade that’s already turning heads—and sparking renewed interest in metal cladding systems. With sustainability and durability driving modern construction, metal clad solutions are surging in popularity across residential and commercial projects alike.

But what exactly does ‘metal clad‘ mean? And why are builders, designers, and engineers choosing it over traditional materials? Whether you’re considering a metal clad house, researching clad steel for industrial use, or just curious about metal clad wire, this guide breaks it all down.

2. What Does ‘Metal Clad’ Mean?

At its core, ‘metal clad‘ (or ‘metalclad’) refers to any product or structure where one metal is bonded—mechanically, metallurgically, or through electroplating—to another material for enhanced performance. This could mean corrosion resistance, improved strength, better aesthetics, or thermal efficiency.

The term ‘clad metal meaning’ often confuses newcomers, but think of it like a sandwich: a strong base metal (like carbon steel) gets a protective or decorative outer layer (like stainless steel, aluminum, or copper). Common combinations include aluminum clad steel, stainless clad aluminum, and titanium clad sheets.

3. Metal Clad in Architecture: Walls, Roofs, and Facades

Architects love metal cladding for its sleek look, longevity, and low maintenance. Popular choices include:

- Metal clad wall systems using corrugated steel facade panels or vertical standing seam metal siding

- Metal clad roof options like zinc clad roof, colorbond standing seam, or PAC Clad HWP

- Eye-catching exteriors with corten steel siding, copper siding, or zinc metal siding

A standout trend? The rise of the corten steel facade. Known for its rust-like appearance that stabilizes over time, corten steel siding costs more upfront but requires zero painting—making it a favorite for modern metal clad buildings.

Other stylish picks include zinc clad dormer accents, PAC Clad column covers, and even aluminum clad sheet panels that mimic traditional weatherboard—often called ‘metal weatherboard.’

4. Industrial & Technical Uses of Clad Metals

Beyond buildings, clad metals play a critical role in engineering and manufacturing. Examples include:

- Aluminum clad stainless steel tubing for chemical processing

- Copper nickel clad plates for marine environments

- Alloy clad sheets like 2024-T3 clad or 7075-T6 clad used in aerospace

These materials combine the best properties of multiple metals. For instance, aluminum clad steel wire offers conductivity with added strength, while cu clad wire (copper-clad) is common in electronics.

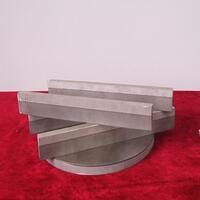

Specialized plates—like boiler plate steel, mild steel plate, or 316 stainless steel plate—are often selected based on thickness (e.g., 1/8 inch steel plate, 3/16 metal plate) and alloy grade for specific industrial demands.

5. Electrical and Insulation Applications

Metal clad isn’t just for exteriors. In electrical systems, metal clad electrical wire (often armored cable) provides robust protection in commercial settings. Yes, it can be used outside—and yes, Pennsylvania permits its use in commercial buildings when installed correctly.

Similarly, aluminum clad pipe insulation wraps ducts and pipes to reflect heat and improve energy efficiency. This ‘metal clad insulation’ is standard in HVAC and industrial plants.

Don’t confuse it with metal clad PCBs (printed circuit boards), which sometimes require baking to remove moisture—but that’s a niche topic for electronics engineers.

6. Popular Metal Clad Products & Systems

Brands like PAC Clad dominate the architectural market with products such as:

- PAC Clad standing seam roof panels

- PAC Clad coping for roof edges

- Pre-finished steel and aluminum panels in dozens of colors

Meanwhile, companies like Steel Clad Inc. specialize in custom metal clad sheds, garages, and steel clad houses built for extreme weather.

For DIYers, exterior corrugated metal siding remains a budget-friendly option—especially when paired with steel plate framing or diamond plate sheet accents for texture.

7. Materials Matter: Steel, Aluminum, Zinc & More

Not all metal cladding is created equal. Key materials include:

- Corten steel plate: Self-protecting, rustic finish

- Aluminum diamond tread plate: Slip-resistant for walkways

- Stainless steel checker plate: Durable and hygienic

- Brass plates for engraving or decorative nameplates

Finishes range from electroplating (like chromium electroplating or gold coating) to advanced overlays like chrome carbide or Inconel 625 weld overlay for extreme wear resistance.

When shopping, you’ll see terms like ‘aluminum 5052 sheet,’ ‘6061-T6 aluminum plate,’ or ‘316L SS plate’—these refer to specific alloy grades that determine strength, weldability, and corrosion resistance.

8. Cost Considerations

Corten siding cost typically runs higher than standard steel—but its lifespan offsets long-term expenses. Similarly, a zinc facade may cost more upfront than aluminum clad steel, but it develops a beautiful patina over decades.

For those sourcing materials, phrases like ‘steel plate for sale,’ ‘aluminum sheet for sale,’ or ‘aluminium checker plate near me’ are common search queries. Prices vary widely by thickness (e.g., 1/4 steel plate vs. 1/8 inch steel plate) and alloy type.

9. Installation & Maintenance Tips

Metal clad siding and roofing should be installed by professionals familiar with thermal expansion and moisture management. Standing seam systems, for example, allow panels to ‘float’ and prevent buckling.

Cleaning is simple: rinse with water or use mild soap. Avoid abrasive tools on finishes like copper or zinc. And yes—you can paint metal clad windows or doors if needed, though many prefer the natural aging process.

10. Conclusion

From the sleek lines of a steel clad building to the hidden strength of aluminum clad wire, ‘metal clad’ represents innovation at the intersection of form and function. Whether you’re designing a home with a corten steel facade or specifying clad metals for an industrial reactor, understanding these materials unlocks smarter, longer-lasting solutions.

As sustainable design continues to evolve, expect metal clad systems—durable, recyclable, and endlessly adaptable—to remain at the forefront of modern construction.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 10. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.