1. Introduction

Just 24 hours ago, NASA announced a breakthrough in thermal protection systems for its next-generation lunar lander—using titanium-clad composite panels that withstand extreme temperature swings on the Moon’s surface. This isn’t your average sheet metal; it’s a precision-engineered clad metal system where titanium is bonded to lightweight alloys to create unmatched durability and heat resistance. And while most people associate ‘metal clad’ with roofing or siding, the reality is far more fascinating.

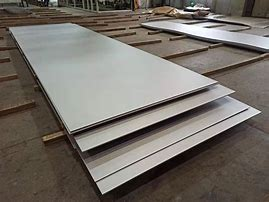

Metal clad—often spelled as ‘metalclad’ in technical contexts—refers to materials made by bonding two or more metals into a single composite. The resulting product combines the best properties of each layer: corrosion resistance, strength, conductivity, or aesthetics. From skyscrapers wrapped in corten steel facade panels to submarines lined with copper-nickel clad piping, these hybrid materials are quietly revolutionizing high-stakes industries.

2. Aerospace & Defense: Titanium Clad for Extreme Environments

In aerospace, weight savings and performance are non-negotiable. That’s why engineers increasingly turn to titanium clad composites. For example, aluminum clad stainless steel or titanium-clad aluminum sheets are used in jet engine housings and satellite components. These clad metals offer the lightness of aluminum with the oxidation resistance of titanium—critical when operating above 600°C.

Recent developments include 7075-T6 clad aluminum plates used in drone airframes, where the pure aluminum cladding protects the high-strength core from environmental degradation without adding significant mass. Similarly, Inconel 625 weld overlays on stainless steel plate bases create turbine blades that survive corrosive combustion byproducts.

3. Marine Engineering: Copper-Nickel Clad for Corrosion Resistance

Saltwater is brutal on metals—but not on copper nickel clad systems. Ships, offshore platforms, and desalination plants rely on pipes and heat exchangers made from cupro nickel clad steel. The copper-nickel outer layer resists biofouling and pitting, while the steel core provides structural integrity.

Aluminum clad pipe insulation is also gaining traction here, offering thermal efficiency without galvanic corrosion risks. These systems outperform traditional zinc-coated or mild steel plate alternatives in longevity and maintenance cost.

4. Sustainable Architecture: Beyond Basic Metal Clad Siding

Forget the old image of a corrugated metal shed. Today’s metal clad building designs are feats of sustainability and style. Architects specify zinc metal siding for its self-healing patina, or corten steel siding for its dramatic rusted aesthetic that requires zero paint.

- Corten steel facade panels are now standard in eco-conscious commercial builds, with corten siding cost dropping as fabrication scales.

- Zinc clad dormers and pac clad standing seam roofs (like PAC Clad HWP systems) offer 80+ year lifespans with minimal upkeep.

- Vertical standing seam metal siding in colorbond or copper finishes turns a steel clad house into a modern sculpture.

Even small elements like pac clad column covers or pac clad coping add refined detail while protecting underlying structures from weather.

5. Energy & Infrastructure: Clad Metals in High-Pressure Systems

Power plants and refineries demand materials that won’t fail under pressure—literally. Boiler plate steel is often upgraded with stainless clad aluminum or alloy clad layers to resist sulfidation and hydrogen embrittlement.

For instance, ASTM A387 carbon steel plates are frequently clad with 316L stainless steel for reactor vessels. The clad metal meaning here is clear: safety through layered defense. Similarly, chrome carbide overlay plates protect coal chutes and cyclones from abrasion far better than solid chromium plate ever could.

6. Electronics & Wiring: Precision in Every Strand

Not all metal clad applications are structural. Metal clad electrical wire—such as aluminum clad steel wire or cu clad wire—is essential in telecom and power transmission. The steel core gives tensile strength, while the aluminum or copper cladding ensures conductivity.

In printed circuit boards, metal clad PCBs use aluminum or copper bases for superior heat dissipation, especially in LED lighting and EV chargers. And yes, metal clad wire can be used outside and in commercial buildings (including Pennsylvania), provided it meets NEC standards for armor and grounding.

7. Specialty Manufacturing: From Diamond Plate to Nameplates

Even niche fabricators benefit from clad innovation. Stainless steel diamond plate with an aluminum tread plate core offers slip resistance without the weight penalty. Brass plates for engraving are often nickel silver clad for enhanced polish retention.

Meanwhile, perforated plate systems made from 316 stainless steel plate or aluminum checker plate serve dual roles in filtration and design. And for branding? Custom metal nameplates often use electroplating gold or chromium electroplating over brass metal plate for luxury finishes.

8. Conclusion

Metal clad isn’t just about wrapping steel in another metal—it’s a strategic fusion of properties that solves problems pure metals can’t tackle alone. Whether it’s a zinc clad roof aging gracefully in the rain, a titanium-clad satellite surviving lunar nights, or aluminum clad stainless steel enabling cleaner energy, clad metals are the unsung heroes of advanced engineering. As material science evolves, expect even more surprising applications of this versatile technology.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.