1. Introduction

Just 24 hours ago, a major architectural firm in Copenhagen unveiled a new eco-office complex featuring a striking corten steel facade paired with zinc clad dormers and vertical standing seam metal siding—a design that’s already sparking conversations across sustainability and construction circles. This surge in metal-clad innovation reflects a broader global shift toward resilient, low-maintenance, and visually dynamic building exteriors. But what exactly does ‘metal clad’ mean, and why is it dominating everything from metal clad houses to industrial sheds and even electrical systems?

At its core, the metal clad meaning refers to any structure, component, or surface that’s covered or ‘clad’ with a layer of metal. This technique—known as cladding—serves both functional and aesthetic purposes, offering protection against weather, fire, corrosion, and wear while delivering sleek, modern visual appeal. Whether you’re looking at a steel clad building downtown, a metal clad shed in your backyard, or even metal clad electrical wire running through your walls, the principle remains the same: a base material enhanced by a metal skin.

2. Understanding Clad Metals and Their Applications

2.1. What Is Clad Metal Meaning in Engineering and Construction?

Clad metals are composite materials created by bonding two or more different metals together—often through roll bonding, explosion bonding, or electroplating. This process combines the best properties of each metal: for instance, aluminum clad stainless steel merges the corrosion resistance of stainless steel with the lightweight nature of aluminum. Similarly, stainless clad aluminum and titanium clad variants are used in aerospace, chemical processing, and marine environments where performance under stress is critical.

Common examples include copper nickel clad for marine hardware, 2024 T3 clad aluminum for aircraft skins, and nickel brass clad copper for specialized electrical applications. The term ‘alloy clad’ also appears frequently in high-performance contexts, such as Inconel 625 weld overlay on boiler plate steel to resist extreme heat and oxidation.

2.2. Metal Clad in Architecture: Walls, Roofs, and Facades

In architecture, metal clad wall systems have exploded in popularity thanks to their durability, design flexibility, and sustainability. A metal clad house might feature corten steel siding for its rustic, self-weathering patina—or a zinc metal siding for a clean, minimalist look that ages gracefully. Corten steel siding cost remains higher than traditional materials, but its near-zero maintenance and 50+ year lifespan make it a smart long-term investment.

Popular systems include colorbond standing seam, PAC CLAD standing seam roof panels, and corrugated steel facade treatments. Vertical standing seam metal siding offers a modern linear aesthetic, while exterior corrugated metal siding brings industrial charm to everything from cafes to luxury homes. Zinc clad roofs and PAC CLAD coping details add refined finishing touches that architects love.

Other standout options include copper siding for heritage-inspired designs, aluminum clad sheet for lightweight cladding, and PAC CLAD column covers that transform structural elements into design features. Even small details like a zinc clad dormer can elevate a building’s curb appeal dramatically.

2.3. Beyond Aesthetics: Functional Metal Cladding

Not all metal cladding is about looks. Metal clad insulation—often using aluminum clad pipe insulation—is critical in HVAC and industrial piping to prevent heat loss and condensation. Similarly, metal clad wire (including aluminum clad steel wire and CU clad wire) is widely used in commercial and industrial electrical installations for its mechanical protection and grounding capabilities.

Metal clad electrical wire is especially common in Pennsylvania and other states with strict commercial building codes, where its armored sheathing provides fire resistance and durability. It can be surface-mounted or run through walls, making it versatile for retrofits and new builds alike.

3. Industrial and Material Foundations: Plates, Sheets, and Alloys

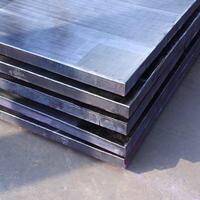

Beneath every metal facade or clad system lies a foundation of engineered metal products. Steel plate—especially mild steel plate, carbon steel plate, and corten steel plate—forms the backbone of structural frames. Meanwhile, stainless steel plate (including 316 stainless steel plate and 304L variants) is chosen for corrosive environments.

Specialty plates like diamond plate steel, aluminum diamond tread plate, and checker plate metal sheet add slip resistance for stairs, truck beds, and walkways. Aluminum 5052 sheet and 6061 T6 aluminum plate are favorites for fabrication due to their weldability and strength-to-weight ratios.

For extreme conditions, engineers turn to Inconel 718 plate, titanium alloy plate, or chrome carbide overlay plates that withstand abrasion in mining and power generation. Even niche items like brass plates for engraving or nickel sulfamate plating serve vital roles in instrumentation and electronics.

4. Trends and Considerations in Modern Metal Cladding

Today’s builders prioritize sustainability, and metal cladding delivers: most systems are 100% recyclable, require no painting, and last decades. Corten siding cost may deter some, but alternatives like PAC CLAD HWP (high-performance prefinished panels) offer similar aesthetics at lower price points.

When selecting a metal clad type, consider climate, maintenance expectations, and local building codes. For example, zinc and aluminum perform well in coastal areas, while corten steel thrives in dry climates where its rust layer stabilizes. Always verify compatibility—like using stainless steel fasteners with aluminum cladding to avoid galvanic corrosion.

5. Conclusion

From the sleek steel facade of a downtown skyscraper to the humble metal clad shed in a suburban backyard, metal cladding is more than a trend—it’s a versatile, future-proof solution rooted in engineering excellence and design innovation. Whether you’re specifying clad metals for a reactor vessel or choosing metal weatherboard for your home, understanding the range of options—from copper siding to aluminum clad stainless steel—ensures you get performance, beauty, and longevity in one package.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.