1. Introduction

Just 24 hours ago, major U.S. steel distributors announced a 7% price drop on corten steel plate and aluminum clad sheet due to eased global tariffs—making now the perfect time to consider metal clad exteriors for your home or shed. Whether you’re building a new metal clad house or upgrading an old facade, this guide gives you everything you need to install and maintain metal clad walls correctly.

Metal clad isn’t just industrial—it’s stylish, durable, and increasingly popular in residential design. From corrugated steel facade to sleek vertical standing seam metal siding, the options are vast. But without proper installation and care, even the best clad metals can underperform.

2. Choosing the Right Metal Clad Type

Not all metal clad is created equal. Your choice depends on climate, budget, and aesthetic goals.

- Corten steel siding offers a rustic, weathered look and is ideal for modern homes—but check corten siding cost before committing; it’s pricier than standard options.

- Zinc metal siding and zinc clad roof systems provide excellent corrosion resistance and age beautifully.

- For a classic look, consider exterior corrugated metal siding or metal weatherboard in Colorbond standing seam finishes.

- Aluminum clad steel or stainless clad aluminum blends strength with light weight—great for metal clad sheds or accent walls.

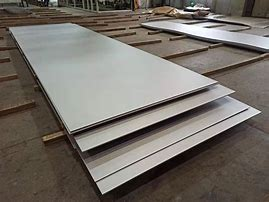

Also, understand the clad metal meaning: it refers to a composite material where a base metal (like mild steel plate) is bonded with a corrosion-resistant layer (like copper, zinc, or titanium). This gives you the strength of steel with the durability of premium metals.

3. Preparing for Installation

Before you install your metal clad wall, gather these essentials:

- Measuring tape and level

- Corrosion-resistant fasteners

- Proper underlayment or metal clad insulation

- Cutting tools rated for metal sheet cutting (e.g., aviation snips or a metal shear)

Ensure your wall structure can support the weight of your chosen material—especially if using thick steel plate or stainless steel metal plate. For vertical standing seam metal siding, furring strips are often needed to create an air gap behind the panels.

4. Step-by-Step Installation Guide

Follow these steps for a clean, long-lasting metal clad wall:

4.1. Install a Weather-Resistive Barrier

Wrap your wall frame with a high-quality housewrap or rigid insulation board. This prevents moisture intrusion and improves energy efficiency—critical for metal clad buildings in humid climates.

4.2. Attach Furring Strips (If Needed)

For standing seam facade or PAC Clad standing seam roof panels used vertically, mount horizontal furring strips every 16–24 inches. This creates drainage and ventilation behind the metal.

4.3. Cut and Fit Panels

Use precise measurements to cut your aluminum clad sheet, zinc clad dormer panels, or corrugated steel facade pieces. Always wear safety gear—metal edges are sharp!

4.4. Secure Panels with Proper Fasteners

Use hidden clips for standing seam systems or exposed fasteners for corrugated styles. Never over-tighten—metal expands and contracts with temperature.

4.5. Seal Joints and Edges

Apply compatible sealant at seams, corners, and around windows. For roof-to-wall transitions, use PAC Clad coping or column covers for a clean finish.

5. Common Problems and How to Fix Them

Even the best metal clad wall can face issues. Here’s how to troubleshoot:

- Rust spots on steel clad? This usually means the protective coating was scratched during install. Touch up with matching paint or a zinc-rich primer.

- Condensation behind panels? Improve ventilation or add metal clad insulation with a vapor barrier.

- Loose panels? Check fastener type—aluminum clad steel wire or standard screws may not hold in high-wind zones. Upgrade to stainless steel fasteners.

- Fading color? UV exposure affects some finishes. Choose PVDF-coated options like PAC Clad HWP for better longevity.

6. Maintenance Tips for Longevity

Metal clad siding is low-maintenance but not zero-maintenance.

- Rinse annually with water to remove salt, pollen, or pollution buildup—especially for coastal homes with copper siding or zinc facade.

- Inspect fasteners and seals every 2 years.

- Avoid abrasive cleaners on stainless plate or chrome metal surfaces.

For metal clad electrical wire or aluminum clad pipe insulation on exterior runs, ensure conduit is rated for outdoor use and properly grounded.

7. Conclusion

Installing a metal clad wall is a smart investment in durability, style, and sustainability. With recent drops in steel plate price and wider availability of materials like 6061 T6 aluminum plate or 316 stainless steel sheet, there’s never been a better time to go metal. Whether you choose corten steel siding, a zinc clad roof, or a sleek steel facade, following these steps ensures your metal clad house stands strong for decades.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as How. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.