1. Introduction

Just 24 hours ago, a major construction firm in Texas halted work on a high-profile commercial development due to premature corrosion on its newly installed zinc clad roof—a stark reminder that even premium metal clad systems demand proper handling and maintenance. Whether you’re building a metal clad house, installing a corten steel facade, or running metal clad electrical wire, knowing how to avoid and fix common pitfalls can save time, money, and headaches.

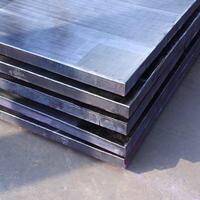

Metal clad—sometimes written as metalclad—refers broadly to structures or components where a base material is covered with a protective or decorative metal layer. From clad metals used in aerospace to everyday applications like metal clad siding or aluminum clad pipe insulation, this versatile technique offers durability, weather resistance, and modern aesthetics. But without the right know-how, problems can arise quickly.

2. Rust and Corrosion on Metal Clad Walls and Roofs

One of the top complaints with metal clad buildings is unexpected rust, especially on steel plate or mild steel plate surfaces that weren’t properly treated. Even stainless steel plate can suffer in harsh coastal environments if the wrong grade (like 304 instead of 316 stainless steel plate) is used.

To prevent or fix this:

- Always verify the clad metal meaning and composition before purchase—e.g., aluminum clad steel combines corrosion resistance with strength.

- For existing rust on a metal clad wall or corrugated steel facade, clean the area with a wire brush, apply a rust converter, then seal with a high-quality metal primer and topcoat.

- Consider upgrading to corten steel siding or zinc metal siding, which form protective patinas over time. Note: corten siding cost is higher upfront but often lower long-term due to minimal maintenance.

3. Improper Installation of Metal Clad Roofing and Siding

Gaps, buckling, or leaks often stem from incorrect installation of systems like colorbond standing seam, pac clad standing seam roof, or vertical standing seam metal siding. These issues compromise both performance and appearance.

Follow these steps for a flawless install:

- Use manufacturer-recommended fasteners and clips—e.g., snap clad clips for certain profiles.

- Allow for thermal expansion; metal expands and contracts with temperature changes.

- Ensure proper overlap and sealing at joints, especially around penetrations like pac clad coping or pac clad column covers.

- For sheds or small structures, exterior corrugated metal siding must be secured to framing every 24 inches to prevent wind uplift.

4. Electrical and Safety Concerns with Metal Clad Wiring

Metal clad electrical wire (often called MC cable) is common in commercial and residential builds, but misuse can create fire or shock hazards. Questions like “Can metal clad wire be used outside?” or “Do AFci breakers need to be installed if the circuit is armored metal clad?” come up often.

Key guidelines:

- Yes, metal clad wire can be used outside—but only if rated for wet locations (look for THWN-2 or similar).

- Always connect metal clad cable to junction boxes using proper MC connectors to maintain grounding.

- In Pennsylvania and most U.S. jurisdictions, MC cable is permitted in commercial buildings when installed per NEC Article 330.

- Never cut metal clad cable with standard pliers—use a rotary cable cutter to avoid damaging the internal conductors or armor.

5. Aesthetic Mismatches and Finishing Issues

A metal clad house can look stunning with the right materials—think copper siding, zinc clad dormer, or a sleek steel facade—but poor coordination leads to clashing textures or colors. For example, pairing a rustic corten steel plate with glossy pac clad hwp trim can look jarring.

Solutions include:

- Create a material board before ordering: include samples of your chosen metal clad siding, roof, and trim (e.g., aluminum clad sheet vs. stainless metal sheet).

- Use consistent finishes: if you choose a standing seam facade, extend that language to soffits and fascias.

- For repainting metal clad window trim or doors, clean thoroughly, sand lightly, and use a metal-specific paint system. Avoid painting over uncleaned chalky surfaces.

6. Insulation and Thermal Performance Gaps

Many assume metal clad buildings are inherently energy-efficient, but without proper metal clad insulation, they can suffer from condensation and heat loss—especially in sheds or steel clad buildings used year-round.

Best practices:

- Install continuous insulation (like rigid foam or aluminum clad pipe insulation) behind the metal skin.

- Use vapor barriers correctly to prevent moisture buildup between the metal and substrate.

- For roofs, consider insulated metal panels (IMPs) that combine structure, insulation, and finish in one system.

7. Conclusion

Working with metal clad systems—whether it’s clad steel for structural elements, titanium clad for specialty applications, or everyday metal weatherboard—requires attention to material selection, installation technique, and long-term maintenance. By addressing these five common problems proactively, you’ll ensure your metal clad building stands strong, looks sharp, and performs well for decades. Always consult local codes and manufacturer specs, especially when dealing with electrical, roofing, or facade systems like pac clad or corten steel.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 5. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.