1. Introduction

Just 24 hours ago, Copenhagen’s new Climate Innovation Hub unveiled its striking facade—a seamless blend of zinc clad roof elements, vertical standing seam metal siding, and corten steel plate accents—designed to achieve net-zero energy use while withstanding harsh Nordic weather. This project exemplifies a global surge in using metal clad systems not just for looks, but as functional, high-performance building skins.

Gone are the days when ‘metal clad‘ simply meant a utilitarian shed or industrial warehouse. Today, architects and engineers leverage clad metals like aluminum clad steel, titanium clad panels, and copper nickel clad composites to create buildings that are energy-efficient, low-maintenance, and visually dynamic. In this article, we’ll dive into how these niche applications are transforming everything from urban skyscrapers to private residences.

2. What Is Metal Clad? Understanding the Basics

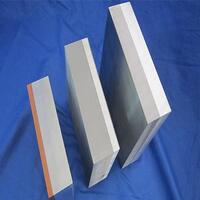

At its core, metal clad meaning refers to a composite material where two or more metals are bonded together—often through roll bonding, explosion cladding, or electroplating—to combine the best properties of each. For example, stainless clad aluminum offers the corrosion resistance of stainless steel with the lightweight nature of aluminum.

Clad metal meaning extends beyond architecture—it’s used in aerospace (like 2024 T3 clad aluminum), chemical processing (inconel 625 weld overlay), and even cookware. But in construction, ‘metal clad’ typically describes exterior systems: metal clad wall panels, metal clad roofs, or full metal facade assemblies.

3. High-Performance Architectural Applications

Modern sustainable design demands materials that perform under stress—thermal cycling, salt spray, UV exposure, and pollution. Metal clad building systems meet these challenges head-on.

Corten steel facade systems, for instance, develop a self-protecting rust patina that eliminates the need for painting. Though corten siding cost is higher upfront—typically $8–$15 per square foot—the lifecycle savings and dramatic aesthetic make it a favorite for cultural institutions and luxury homes alike.

Meanwhile, zinc metal siding and zinc clad dormer elements offer natural antimicrobial properties and 80+ year lifespans. Paired with pac clad standing seam roof systems or pac clad coping details, they create monolithic, watertight envelopes ideal for coastal or high-humidity zones.

- Aluminum clad stainless steel sheets provide fire resistance and reflectivity for curtain walls.

- Copper siding ages gracefully into a green patina, often used in heritage-sensitive districts.

- Exterior corrugated metal siding made from galvanized or colorbond standing seam profiles delivers rapid installation and storm resilience.

4. Beyond Aesthetics: Functional Innovations

It’s not just about looks. Metal clad insulation systems—such as aluminum clad pipe insulation wrapped around HVAC ducts—reduce thermal bridging in commercial builds. Similarly, metal clad electrical wire (including cu clad wire and aluminum clad steel wire) ensures safety in high-risk environments like labs or data centers.

In structural contexts, steel clad inc and steel plate composites reinforce load-bearing elements. Thick steel plate grades like ASTM A387 or 316L stainless steel plate are often clad with nickel or titanium for chemical resistance in industrial facilities.

Even small components benefit: pac clad column covers protect structural steel while matching the building’s metal facade, and metal nameplates made from brass plates for engraving or stainless steel diamond plate add durability to signage.

5. Residential Revolution: The Rise of the Metal Clad House

Homeowners are embracing the metal clad house trend for its modern appeal and resilience. Steel clad houses in wildfire-prone California use 1/4 steel plate or corten steel plate exteriors that resist ember ignition. In snowy regions, standing seam facade systems shed snow effortlessly.

Options like vertical standing seam metal siding or aluminum diamond tread plate accents blend industrial charm with residential comfort. And with finishes ranging from matte black to iridescent copper, customization is limitless.

For DIY builders, corrugated steel facade kits and pac clad hwp (horizontal wall panel) systems simplify installation without sacrificing performance. Plus, metal weatherboard alternatives now mimic traditional wood grain—proving metal clad siding can be warm, not cold.

6. Material Selection Matters

Choosing the right clad metal type depends on climate, budget, and design goals. Aluminum 6061 T6 plate offers strength-to-weight ratio for cantilevered elements. Stainless steel 316 sheet resists salt corrosion near oceans. For interiors, aluminum checker plate or diamond plate steel adds slip resistance in garages or workshops.

When sourcing, look for reputable suppliers offering steel plate for sale with certified grades—whether it’s 3/16 metal plate for framing or 3mm aluminium checker plate for decorative soffits. Always verify compatibility; for example, avoid direct contact between copper and aluminum to prevent galvanic corrosion.

7. Conclusion

From the zinc clad roof of a Copenhagen innovation hub to a steel clad house in Montana, metal clad systems are proving indispensable in next-gen architecture. They merge engineering precision with artistic expression, offering solutions that are as durable as they are beautiful. As sustainability standards tighten and design expectations rise, expect clad metals—from titanium plate to alloy clad composites—to play an even bigger role in shaping our built environment.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Metal. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.