1. Introduction

Just 24 hours ago, Foster + Partners unveiled their latest sustainable skyscraper in Copenhagen, featuring a dynamic facade made entirely of zinc-clad panels and vertical standing seam metal siding—reigniting global interest in advanced metal cladding solutions. This project exemplifies how ‘metal clad‘ has evolved far beyond basic roofing or siding into a sophisticated architectural language that merges engineering precision with visual drama.

Gone are the days when metal cladding meant only corrugated steel sheds or industrial warehouses. Today, designers leverage clad metals—like aluminum-clad stainless steel, titanium-clad composites, and corten steel plate—to create buildings that are not just weather-resistant but also carbon-conscious and visually iconic. Whether it’s a steel clad house in the Pacific Northwest or a PAC CLAD coping system on a Manhattan penthouse, metal clad is redefining modern exteriors.

2. What Does ‘Metal Clad’ Really Mean?

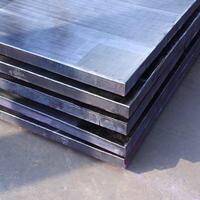

At its core, ‘clad metal meaning’ refers to a composite material where two or more metals are bonded together—typically through roll bonding, explosion welding, or electroplating—to combine the best properties of each. For instance, stainless clad aluminum offers the corrosion resistance of stainless steel with the lightweight nature of aluminum. Similarly, copper nickel clad or inconel 625 overlay plates deliver extreme durability in harsh environments.

This hybrid approach is crucial in architecture. A ‘metal clad wall’ might use a base of mild steel plate for structural support, overlaid with a thin layer of zinc or copper siding for weather protection and aesthetic appeal. The result? Long-lasting, low-maintenance exteriors that age gracefully—like corten steel siding, which develops a rust-like patina that actually protects the underlying steel.

3. Niche Applications in Contemporary Architecture

One of the most exciting niche uses of metal clad today is in high-end residential and commercial facades. Architects are specifying materials like zinc metal siding for its self-healing oxide layer, or colorbond standing seam systems for seamless, clean lines. In alpine regions, zinc clad dormers resist snow load and UV degradation better than traditional wood or vinyl.

Take the rising trend of ‘steel facade’ designs using corrugated steel facade panels—not just for industrial chic, but for thermal mass and recyclability. Meanwhile, PAC CLAD column covers and PAC CLAD HWP (High Wall Panel) systems are being used in luxury developments for their precision-engineered joints and wind-load resistance. These aren’t just functional; they’re sculptural.

Another emerging application is aluminum clad pipe insulation wrapped in perforated plate metal sleeves for both thermal efficiency and visual continuity with the building’s exterior. Even metal nameplates on entryways are now crafted from brass plates for engraving or stainless steel diamond plate for tactile contrast.

4. Material Innovations Driving the Trend

Recent advances in alloy technology have expanded what’s possible with clad metals. Titanium clad panels, though costly, offer unmatched strength-to-weight ratios and are appearing in coastal projects where salt corrosion destroys conventional materials. Similarly, 7075 T6 clad aluminum plates—common in aerospace—are now being repurposed for ultra-thin, high-strength facade elements.

Electroplating techniques like chromium electroplating or electroless nickel deposition allow designers to apply micro-thin protective layers without altering dimensions—ideal for intricate metal weatherboard profiles or aluminum diamond tread plate used in elevated walkways. And for those seeking warmth, copper siding remains a premium choice, developing a rich green patina over decades.

Even insulation is getting a metal upgrade: metal clad insulation combines rigid foam cores with aluminum clad sheet exteriors, creating thermally efficient wall assemblies that double as finished surfaces. This is especially popular in net-zero energy homes using steel clad building systems.

5. Cost, Sustainability, and Practical Considerations

While corten siding cost can run $8–$15 per square foot—higher than standard metal siding—the lifecycle savings in maintenance and longevity often justify the investment. Corten steel siding cost includes no need for painting or sealing, and its 100% recyclability aligns with green building standards like LEED and BREEAM.

For builders, compatibility matters. Aluminum clad steel wire is commonly used in grounding systems for metal clad buildings, while metal clad electrical wire ensures fire resistance in commercial installations. When sourcing materials, terms like ‘steel plate price,’ ‘aluminum sheet for sale,’ or ‘stainless steel plate distributors’ frequently appear in procurement specs—especially when matching facade elements to structural components like steel base plates or thick steel plate supports.

Installation also demands expertise. Standing seam siding requires precise clip placement to accommodate thermal expansion, and PAC CLAD standing seam roofs must be detailed with compatible flashings like PAC CLAD coping to prevent leaks. But when done right, the result is a monolithic, rain-screened envelope that’s as durable as it is beautiful.

6. Conclusion

From corten steel plate accents to titanium-clad canopies and zinc-clad roofs, metal clad has transcended its utilitarian roots to become a cornerstone of high-performance, expressive architecture. As material science advances and sustainability drives design, expect to see even more innovative uses of clad metals—from stainless steel checker plate stair treads to aluminum 6061 T6 plate sunshades. Whether you’re designing a steel clad house or retrofitting a historic structure with vertical standing seam metal siding, the future of exteriors is undeniably metal clad.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Metal. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.