1. Introduction

Just 24 hours ago, architects at the Venice Biennale unveiled a striking pavilion wrapped entirely in a titanium-clad facade—a bold statement on sustainable metallurgy in modern design. This moment highlights a growing global trend: the strategic use of metal clad systems not just for durability, but as aesthetic and functional centerpieces in both residential and industrial projects.

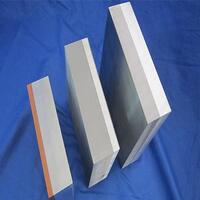

But what exactly does ‘metal clad‘ mean? At its core, metal clad (or metalclad) refers to composite materials where two or more metals are bonded—mechanically, metallurgically, or through electroplating—to combine desirable properties like corrosion resistance, strength, conductivity, or visual appeal. Whether it’s a steel clad house with corrugated steel facade or an aluminum clad pipe insulation system in a refinery, clad metals solve complex engineering challenges elegantly.

2. Understanding Clad Metal Meaning and Types

2.1. What Is Metal Clad?

The term ‘clad metal meaning’ centers on layered construction. Unlike coatings that sit on a surface, cladding integrates dissimilar metals into a single, unified product. For example, stainless clad aluminum merges the light weight of aluminum with the corrosion resistance of stainless steel. Similarly, copper nickel clad or cupro nickel clad materials offer marine-grade durability by fusing copper’s antimicrobial traits with nickel’s toughness.

2.2. Common Metal Clad Types in Industry

Industrial applications rely heavily on specialized clad metals:

- Aluminum clad stainless steel and stainless clad aluminum for heat exchangers

- Titanium clad plates for chemical processing equipment

- Nickel brass clad copper for electrical connectors

- Inconel 625 weld overlay and Inconel weld overlay for high-temperature resistance

These aren’t just theoretical—they’re critical in sectors where failure isn’t an option, from aerospace (7075 T6 clad aluminum) to power generation (ASTM A387 alloy plate).

3. Architectural Metal Clad Systems: From Facades to Roofs

3.1. Metal Clad Walls and Facades

Modern architecture increasingly favors metal clad wall systems for their sleek lines and longevity. Popular choices include:

- Corten steel facade: Known for its rust-like appearance that stabilizes over time; corten steel siding cost ranges from $8–$15/sq.ft., making it premium but low-maintenance.

- Zinc facade and zinc metal siding: Self-healing patina offers decades of service; often used in zinc clad dormer designs.

- Copper siding: Develops a green verdigris over time, prized in heritage and luxury builds.

- Corrugated steel facade and exterior corrugated metal siding: Affordable, rugged, and ideal for industrial or rustic aesthetics.

Vertical standing seam metal siding and standing seam facade systems provide clean, uninterrupted lines—especially when using Colorbond standing seam or PAC Clad HWP panels.

3.2. Metal Clad Roofs and Building Envelopes

A metal clad roof isn’t just about looks—it’s performance-driven. Options like zinc clad roof, PAC Clad standing seam roof, and steel clad roofing offer exceptional weather resistance. Steel clad buildings, including sheds and commercial structures, benefit from minimal upkeep and fire resistance.

PAC Clad coping and PAC Clad column covers extend this system to edges and structural elements, ensuring cohesive design. Meanwhile, metal weatherboard and metal clad siding mimic traditional wood but outlast it by decades.

4. Material Science Behind Cladding: Electroplating and Bonding

How are these composites made? Two primary methods dominate:

Electroplating—such as chromium electroplating or electroless nickel—deposits a thin metallic layer via electric current. This yields chrome metal finishes, gold coating for electronics, or zinc nickel alloy for automotive parts.

Roll bonding or explosion bonding creates true clad metals like aluminum clad steel or alloy clad sheets (e.g., 2024 T3 clad), where layers are fused under high pressure or shockwaves. These are used in everything from aluminum diamond tread plate to stainless steel checker plate.

Common base materials include mild steel plate, carbon steel plate, and specialty alloys like Inconel 718 plate or 6061 T6 aluminum plate. Thickness matters too—1/8 inch steel plate versus 3/16 metal plate affects structural capacity and cost (steel plate price varies widely by grade and supplier).

5. Electrical and Insulation Applications

Beyond architecture, metal clad appears in infrastructure. Metal clad electrical wire—often aluminum clad wire or Cu clad wire—offers shielding and durability. Aluminum clad steel wire is common in telecom and grounding.

Similarly, aluminum clad pipe insulation protects HVAC and industrial piping, combining thermal efficiency with mechanical protection.

6. Conclusion

From the titanium plate on a futuristic pavilion to the humble corrugated steel facade on a backyard shed, metal clad systems bridge function and form. Understanding the nuances—whether you’re comparing corten siding cost to zinc alternatives or evaluating stainless steel plate grades for a project—empowers smarter design and engineering decisions. As material science advances, expect even more innovative metal clad types to emerge, pushing the boundaries of what’s possible in both buildings and machinery.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Metal. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.