1. Introduction

When you hear ‘metal clad,’ you might picture a sleek modern building with shimmering panels or a rugged industrial shed wrapped in corrugated steel. But metal clad is far more versatile—and technically nuanced—than it first appears. From metal clad walls and roofs to specialized clad metals used in piping and wiring, this category spans architecture, engineering, and manufacturing. In this article, we’ll unpack what ‘metal clad’ really means, compare key materials like corten steel, zinc, and aluminum, and explore how different metal clad types serve distinct functional and aesthetic purposes.

2. What Does Metal Clad Mean?

At its core, ‘metal clad‘ (or ‘metalclad’) refers to a composite material or structure where one metal is bonded—mechanically, metallurgically, or through lamination—to another for enhanced performance. The term also broadly applies to buildings or components finished with metal exteriors, such as a metal clad house or metal clad roof. Understanding the ‘clad metal meaning’ is essential: it’s not just surface-level coating but often a layered system designed to combine corrosion resistance, strength, conductivity, or visual appeal.

- Clad metals may involve processes like roll bonding, explosion bonding, or electroplating.

- Common examples include aluminum clad steel, stainless clad aluminum, and titanium clad plates.

3. Architectural Metal Cladding: Aesthetic Meets Function

In construction, metal cladding transforms buildings with durability and design flexibility. Popular choices include corrugated steel facade panels, vertical standing seam metal siding, and premium finishes like zinc facade or copper siding. Each offers unique benefits:

- Corten steel siding develops a rust-like patina that protects against further corrosion—ideal for dramatic, low-maintenance exteriors. However, corten siding cost can be high due to material and fabrication expenses.

- Zinc metal siding and zinc clad roof systems offer longevity (60+ years) and a soft, evolving gray tone. A zinc clad dormer adds refined detail to complex rooflines.

- Colorbond standing seam and PAC Clad standing seam roof systems provide color consistency, weather resistance, and clean lines—often used in both residential and commercial metal clad buildings.

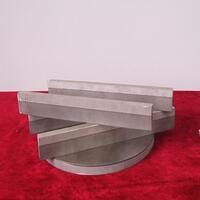

4. Industrial and Structural Clad Metals

Beyond facades, clad metals play critical roles in harsh environments. Boiler plate steel, carbon steel plate, and stainless steel plate are often clad to enhance performance:

- Aluminum clad stainless steel combines the corrosion resistance of stainless with the lightweight nature of aluminum—common in aerospace and chemical processing.

- Copper nickel clad and cupro nickel clad materials resist seawater corrosion, making them ideal for marine applications.

- Alloy clad options like 2024-T3 clad or 7075-T6 clad aluminum sheets improve fatigue resistance in aircraft structures.

Specialized products like aluminum clad pipe insulation or metal clad wire (including CU clad wire and aluminum clad steel wire) leverage conductivity and shielding properties for electrical safety and efficiency.

5. Comparing Key Metal Clad Types

Not all metal cladding is created equal. Let’s compare some widely used systems:

- Steel Clad vs. Aluminum Clad: Steel clad houses offer superior strength and impact resistance but require protective coatings (e.g., zinc coated or galvanized finishes). Aluminum clad steel is lighter and resists rust better but may dent more easily.

- Corten Steel Plate vs. Stainless Steel Plate: Corten forms a stable oxide layer; stainless relies on chromium content (e.g., 316 stainless steel plate) for passive corrosion resistance. Corten is cheaper upfront but may stain adjacent surfaces during weathering.

- Zinc Clad vs. Copper Siding: Zinc is more affordable and sustainable; copper offers unmatched longevity and develops a green patina over decades. Both suit high-end architectural projects.

6. Practical Considerations: Cost, Installation, and Maintenance

Choosing the right metal clad type depends on budget, climate, and design goals. For instance, exterior corrugated metal siding is cost-effective for sheds or agricultural metal clad sheds, while PAC Clad column covers or PAC Clad coping add refined detailing to upscale builds. Standing seam facade systems—like vertical standing seam metal siding—require skilled installation but minimize leaks and thermal bridging.

Maintenance varies: stainless metal sheet and aluminum diamond tread plate need little care, whereas mild steel plate or 1/4 steel plate must be painted or coated to prevent rust. Always consider local availability—searching for ‘steel plate near me’ or ‘aluminium checker plate near me’ can affect lead times and costs.

7. Conclusion

Metal clad isn’t just a trend—it’s a smart fusion of form and function across industries. Whether you’re selecting corten steel facade panels for a modern home, specifying aluminum clad sheet for industrial ductwork, or wiring with metal clad electrical cable, understanding the nuances of each metal clad type ensures optimal performance and value. From boiler plate steel to titanium plate overlays, the world of clad metals continues to evolve—offering solutions that are as durable as they are beautiful.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Metal. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.