1. Introduction

When you hear ‘metal clad,’ your mind might jump to sleek modern homes with corrugated steel facades or industrial facilities wrapped in durable steel cladding. But metal clad isn’t just one thing—it’s a broad category encompassing everything from exterior building envelopes to specialized composite metals used in high-performance engineering. Whether you’re designing a metal clad house, selecting standing seam siding, or sourcing clad steel for pressure vessels, understanding the nuances between types is crucial. This deep dive unpacks what metal clad really means, breaks down popular variants like corten steel facade and zinc metal siding, and compares their real-world performance so you can choose wisely.

2. Understanding Metal Clad: Meaning and Core Concepts

The term ‘metal clad’ (or ‘metalclad’) broadly refers to materials or structures that feature a metal layer bonded to another substrate—either for protection, aesthetics, conductivity, or structural reinforcement. In architecture, it often describes exterior surfaces like metal clad walls or roofs. In manufacturing, it may refer to clad metals—composites like aluminum clad stainless steel or titanium clad plates engineered for corrosion resistance without sacrificing strength or cost-efficiency.

- Clad metal meaning: A layered material where two or more metals are metallurgically bonded.

- Metal clad meaning in construction: Exterior building components (walls, roofs, dormers) sheathed in metal for weather resistance and visual impact.

3. Architectural Metal Cladding Systems Compared

3.1 Steel-Based Cladding Options

Steel remains the backbone of many metal clad building designs. From corrugated steel facade panels to vertical standing seam metal siding, steel offers unmatched strength and affordability. Corten steel siding stands out for its self-protecting rust patina, eliminating the need for painting—though corten siding cost runs higher than standard galvanized options. Meanwhile, colorbond standing seam and PAC CLAD HWP systems provide pre-finished, low-maintenance alternatives ideal for both residential and commercial use. Steel clad houses often leverage these systems for longevity, especially in coastal or high-wind zones.

3.2 Zinc and Copper Facades

Zinc clad roof and zinc facade systems offer elegance with minimal upkeep. Zinc naturally develops a protective carbonate layer, resisting corrosion for 80+ years. A zinc clad dormer or zinc metal siding adds a refined, matte-gray finish that architects love. Copper siding, though pricier, evolves into a distinctive green patina over time, making it a premium choice for heritage or high-end projects. Both outperform painted steel in lifespan but come with higher upfront costs.

3.3 Aluminum and Composite Solutions

Aluminum clad steel and aluminum clad sheet dominate lightweight applications. Aluminum’s corrosion resistance makes it ideal for coastal environments, while its reflectivity helps reduce cooling loads. PAC CLAD column covers and coping elements often use aluminum for formability and finish consistency. For insulation, aluminum clad pipe insulation combines thermal efficiency with vapor barrier protection—common in HVAC and industrial piping.

4. Industrial and Engineering Clad Metals

Beyond architecture, clad metals serve critical roles in chemical processing, aerospace, and energy sectors. Here, performance trumps aesthetics.

4.1 Stainless Clad Composites

Stainless clad aluminum and aluminum clad stainless steel merge the corrosion resistance of stainless steel with the light weight or cost savings of aluminum. These are common in heat exchangers, storage tanks, and marine hardware. Similarly, copper nickel clad and cupro nickel clad materials resist biofouling in seawater applications.

4.2 High-Performance Alloy Cladding

For extreme environments, engineers turn to alloy clad systems like Inconel 625 weld overlay on carbon steel plates or titanium clad substrates. These protect base metals like mild steel plate or boiler plate steel from oxidation, acids, or high temperatures. ASTM A387-grade steel plates are often overlaid with chrome carbide for wear resistance in mining equipment.

5. Electrical and Specialty Metal Clad Applications

Metal clad electrical wire—often called MC cable—uses an interlocked aluminum or steel armor for physical protection in commercial buildings. Aluminum clad steel wire and CU clad wire variants balance conductivity and durability. Note: metal clad wiring can be surface-mounted and is permitted in Pennsylvania commercial builds when installed per NEC guidelines.

Meanwhile, metal clad insulation wraps ducts and pipes, using aluminum or stainless exteriors to shield fiberglass or foam cores. Even small components like metal nameplates or brass plates for engraving may use electroplating (e.g., chromium electroplating or gold coating) to enhance appearance or function.

6. Material Selection Guide: Thickness, Grades, and Cost

Choosing the right metal plate or sheet depends on load, environment, and budget. Common thicknesses include 1/8 inch steel plate for light framing or 3/16 metal plate for heavy bases. Grades matter: 316 stainless steel plate resists saltwater better than 304L; 6061-T6 aluminum plate offers excellent weldability; Corten steel plate provides weathering resistance without coatings.

Prices vary widely—steel plate price per pound is lower than titanium plate or Inconel 718 plate—but lifecycle costs often favor premium alloys in harsh settings. Always verify specs: stainless steel plate grades, alloy sheet 3mm tolerances, or whether your aluminum diamond tread plate meets slip-resistance codes.

7. Conclusion

From a rustic corten steel siding accent to a high-tech Inconel 625 overlay in a refinery, metal clad solutions span an incredible range of performance and style. The key is matching the metal clad type to your specific need—whether it’s aesthetic (zinc facade), protective (aluminum clad pipe insulation), structural (steel clad building), or conductive (metal clad wire). By understanding the clad metal meaning across contexts and comparing real-world trade-offs in cost, maintenance, and durability, you’ll avoid over-engineering—or under-specifying—your next project.

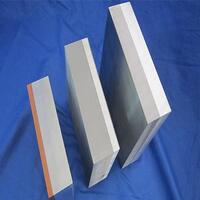

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Choose. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.