1. Introduction

If you’ve ever walked past a modern building with sleek metallic surfaces or driven by a warehouse wrapped in shimmering corrugated panels, you’ve seen metal clad in action. But what exactly is metal clad? At its core, metal clad refers to composite materials made by bonding two or more different metals together—combining the best properties of each for enhanced performance, aesthetics, or cost-efficiency. From metal clad wire used in electrical installations to stunning corten steel facades on high-end homes, this technology spans industries and applications.

In this guide, we’ll unpack the metal clad meaning, explore common metal clad types, and compare key materials like aluminum clad steel, stainless clad aluminum, and titanium clad systems. Whether you’re an architect, contractor, or DIY enthusiast, understanding these differences can help you choose the right solution for your project.

2. What Does ‘Clad Metal Meaning’ Really Refer To?

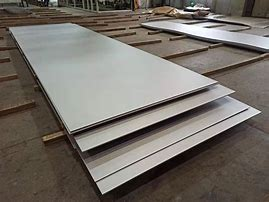

The term ‘clad metal meaning’ describes a layered metal structure where a base metal (like carbon steel) is bonded with a corrosion-resistant or decorative surface layer (such as stainless steel, copper, or zinc). This process—often achieved through roll bonding, explosion bonding, or electroplating—creates a material that’s both economical and high-performing.

For example, aluminum clad stainless steel offers the strength and heat resistance of stainless steel with the lightweight and cost benefits of aluminum. Similarly, copper nickel clad combines copper’s conductivity with nickel’s durability—ideal for marine or chemical environments.

3. Common Types of Metal Clad Systems in Construction

Metal clad isn’t just one thing—it’s a family of solutions tailored to specific needs. Here’s how some popular variants stack up:

- Metal clad wall and metal facade systems often use corrugated steel facade panels, zinc metal siding, or vertical standing seam metal siding for weather resistance and visual impact.

- Metal clad roof options include colorbond standing seam, pac clad standing seam roof, and zinc clad roof systems—each offering unique longevity and aesthetic profiles.

- For residential builds, a metal clad house might feature corten steel siding (known for its rust-like patina) or exterior corrugated metal siding for an industrial-chic look.

Notably, corten steel siding cost tends to be higher than standard galvanized options, but its self-protecting oxide layer reduces long-term maintenance—making it a favorite for architects seeking dramatic, low-upkeep exteriors.

4. Architectural Metal Cladding: Aesthetic Meets Function

When it comes to facades, metal cladding delivers both beauty and resilience. A corten steel facade evolves over time, developing a rich, earthy tone without painting. Meanwhile, a zinc facade offers subtle elegance and exceptional longevity—zinc naturally forms a protective patina that resists corrosion for decades.

Copper siding brings warmth and prestige but requires budget consideration due to material costs. Aluminum clad sheet and stainless steel metal plate are also widely used for column covers (like pac clad column covers), coping (pac clad coping), and dormers (zinc clad dormer), blending seamlessly with modern design languages.

Standing seam facade systems—especially pac clad hwp or colorbond variants—are prized for clean lines, minimal fastener exposure, and superior water shedding, making them ideal for everything from metal clad buildings to upscale metal clad sheds.

5. Beyond Architecture: Industrial and Electrical Uses

Metal clad extends far beyond walls and roofs. In industrial settings, clad metals like boiler plate steel or alloy clad plates (e.g., 7075 T6 clad or 2024 T3 clad aluminum) provide strength with corrosion resistance for aerospace or marine components.

Electrical applications rely heavily on metal clad electrical wire—also called armored cable—which protects conductors with a flexible metal sheath. Aluminum clad steel wire and cu clad wire are common in power transmission, while aluminum clad pipe insulation uses reflective metal layers to reduce thermal loss.

It’s worth noting that terms like ‘metal clad wire’ and ‘aluminum clad wire’ refer to different technologies: the former is armored cabling for safety, the latter describes a conductor with a thin aluminum layer over steel for conductivity and tensile strength.

6. Material Comparisons: Steel, Aluminum, Zinc, and More

Choosing the right metal clad type depends on environment, budget, and design goals. Stainless steel plate (including grades like 316L or 304L) offers unmatched corrosion resistance but at a premium price. Mild steel plate or 1/4 steel plate may serve as cost-effective substrates when clad with a protective layer.

Aluminum diamond tread plate and checker plate metal sheet add slip resistance for walkways, while perforated plate or diamond plate steel sheets suit ventilation or decorative screens. For extreme conditions, inconel plate or titanium alloy plate provide high-temperature stability—often used in chemical processing or jet engines.

Even finishes matter: chromium electroplating creates a shiny, hard chrome metal surface, while electroless nickel or gold coating adds conductivity or luxury appeal for nameplates and electronics.

7. Conclusion

Metal clad is far more than just a buzzword—it’s a versatile engineering solution that merges functionality with form. Whether you’re specifying a corten steel siding for a boutique hotel, installing pac clad standing seam roofing on a commercial hub, or selecting aluminum clad stainless steel for a heat exchanger, understanding the nuances between clad metal types ensures smarter, longer-lasting decisions. As materials science advances, expect even more innovative metal clad composites to emerge—blending sustainability, performance, and striking design.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Understand. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.