1. Introduction

In the past 48 hours, architects and builders have been buzzing about a new wave of sustainable building projects featuring corten steel siding and zinc clad roofs in urban developments across North America. Firms like Steel Clad Inc. are reporting surging demand for metal clad houses that blend durability with modern aesthetics—fueling interest in what exactly ‘metal clad’ means and how different clad metal types perform in real-world applications.

At its core, metal clad refers to composite materials where one metal is bonded—mechanically or metallurgically—to another to combine desirable properties like corrosion resistance, strength, conductivity, or visual appeal. Whether it’s a copper siding accent on a luxury home or aluminum-clad stainless steel used in high-pressure piping, the versatility of clad metals is reshaping both construction and manufacturing.

2. What Is Metal Clad? Understanding the Basics

The term ‘clad metal meaning’ or ‘metal clad meaning’ describes layered metal products engineered for enhanced performance. Unlike simple coatings (like paint or electroplating), true cladding involves bonding two or more distinct metals into a single, inseparable unit. This process can be achieved through roll bonding, explosion welding, or co-extrusion.

Common examples include aluminum clad steel (used in automotive and aerospace), titanium clad for chemical processing equipment, and stainless clad aluminum for heat exchangers. In architecture, this translates to stunning exterior solutions like vertical standing seam metal siding, corrugated steel facades, and pac clad standing seam roofs.

3. Architectural Metal Clad Systems Compared

When designing a metal clad building or house, architects choose from several popular systems—each with unique benefits.

- Corten steel facade: Known for its rust-like appearance that stabilizes over time, corten steel siding offers dramatic visuals with minimal maintenance. However, corten siding cost remains higher than alternatives, averaging $8–$12 per square foot installed.

- Zinc facade and zinc clad roof: Zinc metal siding develops a soft gray patina and lasts over 80 years. A zinc clad dormer adds elegance without frequent upkeep.

- Copper siding: Timeless but expensive, copper ages gracefully and is often used for accents rather than full coverage.

- Exterior corrugated metal siding: Budget-friendly and industrial-chic, especially in mild steel plate or galvanized variants.

- Colorbond standing seam and PAC Clad HWP: These pre-finished steel options offer color consistency, weather resistance, and clean lines via vertical standing seam metal siding or pac clad column covers.

4. Industrial and Electrical Applications of Clad Metals

Beyond facades, clad metals play critical roles in infrastructure and electronics. Aluminum clad wire and metal clad electrical wire are widely used for their lightweight conductivity and shielding properties. Cu clad wire (copper-clad aluminum) balances cost and performance in power transmission.

In piping, aluminum clad pipe insulation protects against thermal loss and corrosion. Meanwhile, alloy clad materials like 2024-T3 clad aluminum or 7075-T6 clad serve aerospace needs by combining high strength with surface durability.

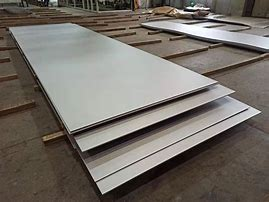

For heavy-duty environments, clad steel plates—such as stainless steel plate bonded to carbon steel—deliver corrosion resistance where it matters most, like in boiler plate steel or marine applications. Even niche products like nickel brass clad copper or cupro nickel clad find use in desalination plants.

5. Material Choices and Performance Factors

Selecting the right metal clad type depends on environment, budget, and function. For instance, a metal clad shed in a coastal area might use 316 stainless steel plate for salt resistance, while an inland metal clad wall could rely on zinc-coated mild steel plate.

Thickness also matters: common gauges include 1/8 inch steel plate for structural backing or 3/16 metal plate for load-bearing elements. Diamond plate steel sheets (like aluminum diamond tread plate or stainless steel checker plate) add slip resistance for walkways or vehicle flooring.

Electroplating processes—such as chromium electroplating or electroless nickel—can enhance surface hardness, but they’re not true cladding. True clad metals, like aluminum clad stainless steel, maintain integrity even if scratched, unlike plated surfaces where base metal exposure leads to rapid corrosion.

6. Cost, Sustainability, and Future Trends

While upfront costs for materials like corten steel plate or titanium plate are high, lifecycle savings from low maintenance and longevity make them attractive. PAC Clad coping and pac clad standing seam roofs now dominate commercial projects due to recyclability and energy efficiency.

Sustainability is driving innovation: many clad metals are fully recyclable, and manufacturers increasingly use recycled content in stainless metal sheet and aluminum sheet for sale. The trend toward minimalist, durable exteriors—seen in steel clad houses with standing seam facades—shows no sign of slowing.

7. Conclusion

From the sleek lines of a zinc facade to the rugged reliability of aluminum clad steel wire, metal clad solutions bridge form and function across industries. Understanding the differences between clad metal types—whether you’re choosing corten steel siding for a home or stainless clad aluminum for industrial piping—ensures smarter, longer-lasting investments. As demand grows for resilient, eco-conscious materials, metal clad isn’t just a trend—it’s the future.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Metal. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.