1. Introduction

Just 24 hours ago, architects and builders at the 2024 GreenBuild Expo in Philadelphia spotlighted a surge in demand for sustainable, low-maintenance building envelopes—especially metal clad systems like corten steel siding and zinc clad roofs. With climate resilience and material longevity topping design priorities, understanding the nuances of metal clad options has never been more critical.

Whether you’re designing a steel clad house, retrofitting a metal clad shed, or selecting insulation for aluminum clad pipe systems, the term ‘metal clad’ covers a surprisingly wide spectrum. In this deep dive, we’ll unpack what ‘clad metal meaning’ really entails, compare top materials, and guide you through choosing the right metal clad type for your specific needs.

2. What Does ‘Metal Clad’ Actually Mean?

At its core, ‘metal clad meaning’ refers to a composite material where a base metal is bonded—mechanically, metallurgically, or through electroplating—to a different metal layer for enhanced performance. This process, known as cladding, combines the structural strength of one metal with the corrosion resistance, aesthetics, or conductivity of another.

Common examples include aluminum clad steel (used in everything from automotive panels to metal clad electrical wire), stainless clad aluminum for heat exchangers, and titanium clad plates for aerospace. The resulting ‘clad metals‘ offer tailored solutions that pure metals often can’t match.

3. Metal Clad in Architecture: Facades, Roofs, and Siding Compared

Architects increasingly specify metal clad wall systems for their sleek look and durability. Let’s compare the most popular choices:

- Corten steel facade: Loved for its rust-like patina that stabilizes over time, corten steel siding delivers dramatic aesthetics with minimal upkeep. However, corten siding cost runs higher than standard steel—typically $8–$15 per sq. ft.—and isn’t ideal for high-humidity coastal zones.

- Zinc facade: Zinc metal siding forms a protective carbonate layer, offering 80+ years of service life. A zinc clad dormer or roof ages gracefully to a soft gray. It’s pricier than aluminum but more sustainable due to 100% recyclability.

- Copper siding: Develops a green patina over decades, adding historic charm. Often used in premium projects like column covers or accent panels (e.g., PAC Clad column covers).

- Aluminum and steel options: Colorbond standing seam and PAC Clad HWP systems dominate residential metal clad roofs thanks to color variety and ease of installation. Vertical standing seam metal siding and exterior corrugated metal siding remain go-to choices for modern metal clad buildings.

4. Beyond Aesthetics: Functional Metal Clad Applications

Not all metal clad uses are visible. Consider these critical functional applications:

- Metal clad wire and electrical systems: Aluminum clad steel wire and CU clad wire offer strength with conductivity. Metal clad electrical wire is widely permitted in commercial buildings in Pennsylvania when installed per NEC guidelines.

- Metal clad insulation: Aluminum clad pipe insulation protects HVAC and industrial piping from moisture and mechanical damage.

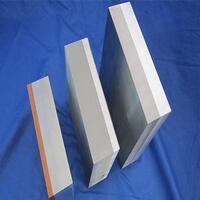

- Structural plates: From 1/8 inch steel plate to thick boiler plate steel, clad variants like aluminum clad stainless steel enhance corrosion resistance in harsh environments. Alloy clad plates—such as 2024-T3 clad or 7075-T6 clad—are standard in aerospace for fatigue resistance.

5. Material Deep Dive: Steel, Aluminum, and Specialty Clads

Steel remains the backbone of many clad systems. Stainless steel plate grades like 316L or 904L are often bonded to carbon steel for chemical plants. Corten steel plate offers weathering resistance without painting.

Aluminum dominates lightweight cladding. Aluminum clad sheet (or aluminium clad sheet) is common in transport and architecture. Aluminum diamond tread plate and checker plate variants add slip resistance for industrial floors.

Specialty clads push performance further: nickel brass clad copper for marine hardware, inconel 625 weld overlay for extreme heat, and chrome carbide overlay plates for mining equipment. Even electroplating methods like chromium electroplating or electroless nickel create functional ‘clad’ surfaces on brass plate, bronze plate, or mild steel plate.

6. Cost, Installation, and Long-Term Value

Initial cost varies widely. Corten steel siding cost may deter budget builds, but its zero-maintenance lifecycle offsets long-term expenses. Zinc clad roof systems cost more upfront than corrugated steel facade options but last decades longer.

Installation ease also matters. Standing seam systems like PAC Clad coping or Colorbond standing seam snap together cleanly, reducing labor. In contrast, custom metal weatherboard or perforated plate accents require skilled fabricators.

Always consider local availability—searching ‘steel plate near me’ or ‘aluminium checker plate near me’ can impact project timelines and budgets.

7. Conclusion

From the dramatic lines of a corten steel facade to the hidden strength of aluminum clad stainless steel in industrial piping, metal clad solutions blend form and function like few other materials. Understanding the clad metal meaning—and the trade-offs between zinc, copper, steel, and aluminum—empowers smarter, more sustainable choices. Whether you’re building a steel clad house or specifying metal clad insulation, match the metal clad type to your environment, budget, and design vision for lasting results.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Choose. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.