1. Introduction

In the past 48 hours, architects and builders across North America have reported a sharp rise in demand for sustainable, low-maintenance exteriors—especially metal clad house designs featuring corten steel siding and zinc clad dormers. With climate resilience and modern aesthetics driving this trend, more homeowners are turning to durable metal cladding solutions. If you’re considering upgrading your home’s exterior or repairing an existing metal clad wall, this step-by-step guide will walk you through everything from material selection to long-term care.

2. Understanding Metal Clad Basics

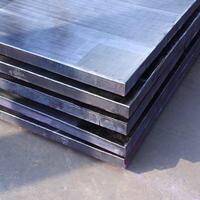

Before diving into installation, it helps to clarify what ‘metal clad’ actually means. The metal clad meaning refers to any building surface—wall, roof, or structure—covered with a layer of metal for protection, durability, or visual appeal. Clad metals can include combinations like aluminum clad steel, stainless clad aluminum, or even titanium clad panels. These aren’t just decorative; they offer weather resistance, fire protection, and longevity.

- Common types include metal clad siding, metal clad roof systems (like pac clad standing seam), and vertical standing seam metal siding.

- Popular materials range from corrugated steel facade and copper siding to zinc metal siding and colorbond standing seam panels.

3. Choosing the Right Metal Clad Type for Your Project

Not all metal cladding is created equal. Your choice depends on climate, budget, and design goals. For example, corten steel siding offers a rustic, weathered look but comes with a higher corten siding cost. Meanwhile, aluminum clad sheet is lightweight and corrosion-resistant—ideal for coastal areas.

3.1. Popular Options Compared

If you’re weighing options, consider these common choices:

- Corten steel facade: Develops a protective rust patina; great for modern industrial looks.

- Zinc facade: Self-healing surface; excellent lifespan with minimal upkeep.

- Exterior corrugated metal siding: Affordable and easy to install; often used on metal clad sheds or barns.

- Pac clad coping and column covers: Architectural accents that blend seamlessly with standing seam facade systems.

4. Step-by-Step Installation of a Metal Clad Wall

Installing a metal clad wall isn’t overly complex, but precision matters. Follow these steps carefully:

4.1. Prepare the Substrate

Ensure your wall framing is level, dry, and structurally sound. Install a moisture barrier (like housewrap) and, if needed, metal clad insulation—such as aluminum clad pipe insulation adapted for walls—to improve energy efficiency.

4.2. Install Furring Strips

Attach horizontal or vertical furring strips (typically wood or metal) to create an air gap behind the cladding. This prevents moisture buildup and allows ventilation.

4.3. Cut and Fit Panels

Use proper tools to cut your chosen material—whether it’s aluminum diamond plate, stainless steel metal plate, or perforated plate. Always wear safety gear. For clean edges, use a metal shear or circular saw with a metal-cutting blade.

4.4. Secure the Cladding

Fasten panels using corrosion-resistant screws compatible with your metal type. For standing seam systems like pac clad hwp, use hidden clips to maintain a seamless appearance. Overlap panels correctly to prevent water intrusion.

5. Common Problems and How to Fix Them

Even the best-installed metal clad walls can face issues over time. Here’s how to troubleshoot:

5.1. Rust or Corrosion

While materials like stainless steel plate or aluminum clad stainless steel resist rust, scratches can expose base metals. Clean affected areas and apply a matching metal primer and paint. For corten steel plate, remember that surface rust is part of its design—not a defect.

5.2. Loose or Noisy Panels

Wind can cause rattling if panels aren’t secured tightly. Re-tighten fasteners or add additional clips. Use rubber washers to reduce noise and prevent galvanic corrosion.

5.3. Poor Drainage or Leaks

Check flashings around windows, doors, and pac clad column covers. Ensure your metal weatherboard system includes proper drip edges and overlaps. Re-seal joints with UV-resistant sealant if needed.

6. Maintenance Tips for Longevity

Metal clad exteriors are low-maintenance but not zero-maintenance. Rinse your metal clad wall annually with mild soap and water to remove dirt and pollutants. Inspect fasteners and seams every spring. For zinc clad roof or siding, avoid abrasive cleaners—they can damage the protective patina.

7. Conclusion

Whether you’re building a new metal clad building or refreshing an old one, understanding the right materials—from alloy clad sheets to copper nickel clad panels—and following proper installation techniques ensures decades of performance. With rising interest in sustainable design and the versatility of options like vertical standing seam metal siding or corrugated steel facade, metal cladding is more than a trend—it’s a smart, stylish investment.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as How. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.