1. Introduction

Just 24 hours ago, a major architectural firm in Portland unveiled a new residential project featuring a striking corten steel facade that’s already sparking conversations across design forums. The home showcases how modern metal clad exteriors—once reserved for industrial buildings—are now defining contemporary aesthetics with durability and low maintenance. If you’re considering upgrading your home or shed with metal cladding, this step-by-step guide will help you navigate installation, material choices, and upkeep like a pro.

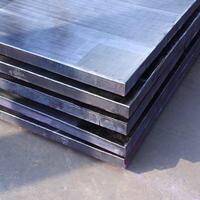

Metal clad isn’t just a buzzword—it’s a versatile solution used in everything from metal clad houses and sheds to commercial facades. Whether you’re drawn to the rustic patina of corten steel siding, the sleek look of a zinc clad roof, or the clean lines of vertical standing seam metal siding, understanding the process ensures your investment lasts decades.

2. Understanding Metal Clad: What It Is and Why It Matters

Before diving into installation, let’s clarify what ‘metal clad‘ actually means. In construction, ‘metal clad meaning’ refers to building components—walls, roofs, or even pipes—covered or sheathed with a layer of metal for protection, aesthetics, or both. This includes everything from metal clad siding and metal clad electrical wire to clad metals like aluminum clad stainless steel or titanium clad sheets used in high-performance applications.

Common types include:

- Corten steel siding (ideal for weather-resistant, self-protecting exteriors)

- Zinc metal siding (low-maintenance with natural aging beauty)

- Copper siding (premium look with long-term patina development)

- Exterior corrugated metal siding (classic industrial style, often used on metal clad sheds)

- Colorbond standing seam or PAC Clad standing seam roof systems (popular for clean, modern homes)

Each offers unique benefits, but all share core advantages: fire resistance, longevity, and minimal upkeep compared to wood or vinyl.

3. Step-by-Step Installation Guide for Metal Clad Wall Systems

3.1. Choose the Right Material for Your Climate and Style

Start by selecting your metal type based on location and design goals. Coastal areas benefit from stainless clad aluminum or aluminum clad steel due to corrosion resistance. For a bold statement, consider a corten steel facade—but note that corten siding cost is higher than standard steel. Budget-friendly options include aluminum clad sheet or pre-finished steel plate with zinc-coated or electroplating finishes.

3.2. Prepare the Substrate Properly

Metal cladding must be installed over a stable, flat, and dry surface. Use plywood or oriented strand board (OSB) sheathing with a weather-resistant barrier (like house wrap). Never attach metal directly to studs without backing—it can lead to oil-canning (waviness) and moisture traps.

3.3. Install Furring Strips for Ventilation

To prevent condensation and extend lifespan, add vertical furring strips (typically 1×2 lumber or metal channels) over the weather barrier. This creates an air gap behind the metal clad wall, allowing moisture to escape—a critical step often overlooked in DIY projects.

3.4. Cut and Fit Panels Accurately

Use metal snips or a circular saw with a metal-cutting blade to trim panels. Always wear safety gear. For standing seam systems like PAC Clad HWP or vertical standing seam metal siding, follow manufacturer specs for clip spacing and panel overlap. Corrugated steel facade panels require precise alignment to maintain pattern continuity.

3.5. Secure Panels Correctly

Fasten panels using color-matched screws designed for metal roofing/siding. Drive screws into the high points of corrugations or designated clip zones for standing seam. Avoid over-tightening, which can distort the metal or compromise seals.

4. Common Problems and How to Avoid Them

4.1. Rust or Corrosion on Steel Clad Surfaces

Even clad steel can corrode if scratched or improperly sealed. Always use factory-finished products with protective coatings (e.g., zinc-coated, chromium electroplating, or alloy clad layers like 2024-T3 clad). Touch up cuts with matching paint or sealant.

4.2. Thermal Expansion Noise

Metal expands and contracts with temperature changes. Allow for movement by not over-constraining panels. Use slotted holes or floating clips where recommended.

4.3. Poor Drainage Leading to Water Intrusion

Install proper flashing at windows, doors, and corners. Use PAC Clad coping and column covers for clean transitions. Ensure bottom edges terminate above grade or into a drip edge to avoid splashback.

5. Maintenance Tips for Longevity

Metal clad exteriors are low-maintenance but not zero-maintenance. Rinse annually with water to remove dirt and pollutants. For tougher grime, use mild soap and a soft brush—never abrasive cleaners on copper siding or zinc facade panels. Inspect fasteners yearly and reseal any penetrations.

If you have a metal clad shed or steel clad building near trees, clear debris regularly to prevent staining or moisture buildup. And remember: while aluminum clad pipe insulation protects internal systems, your exterior cladding needs its own care routine.

6. Conclusion

Installing metal clad siding—whether it’s a corten steel plate accent wall, a full zinc clad dormer, or a sleek steel facade—adds modern elegance and rugged durability to any structure. By choosing the right clad metal meaning for your project, following proper installation techniques, and performing light maintenance, your metal clad house will stand out for decades. With rising interest in sustainable, long-life materials, now’s the perfect time to go metal.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as How. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.