1. Introduction

Just 24 hours ago, a major home renovation expo in Chicago spotlighted the rising trend of sustainable, low-maintenance exteriors—with metal clad siding taking center stage. Architects and builders praised its durability, modern aesthetics, and eco-friendly recyclability, especially materials like corten steel facade and zinc clad dormer systems. If you’re considering upgrading your home’s exterior with metal clad wall panels or troubleshooting an existing installation, you’re in the right place.

Metal clad isn’t just industrial—it’s a design-forward, resilient solution for everything from a metal clad shed to a full steel clad house. But with so many options—aluminum clad steel, copper siding, colorbond standing seam, and more—it’s easy to feel overwhelmed. This guide breaks it all down with clear, actionable steps.

2. Understanding Metal Clad: What Does It Mean?

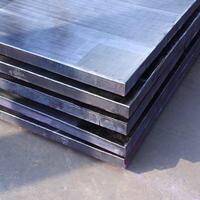

Before diving into installation, let’s clarify the metal clad meaning. ‘Clad metals’ refer to composite materials where a base metal (like steel or aluminum) is bonded with a protective or decorative outer layer—such as zinc, copper, or stainless steel. This process, sometimes achieved through electroplating or roll bonding, enhances corrosion resistance, appearance, and longevity.

Common types include aluminum clad stainless steel for piping, titanium clad for aerospace, and everyday exterior options like corrugated steel facade or vertical standing seam metal siding. Whether you’re working with pac clad standing seam roof panels or corten steel siding, the core principle remains: performance meets style.

3. Choosing the Right Metal Clad Siding

Not all metal clad siding is created equal. Your climate, budget, and design goals will dictate the best choice:

- Corten steel siding: Rustic, self-weathering look; ideal for modern homes. Note: corten siding cost is higher but requires zero painting.

- Zinc metal siding: Develops a soft patina over time; great for coastal areas due to salt resistance.

- Aluminum clad steel: Lightweight, rust-resistant, and affordable—perfect for metal clad buildings in humid regions.

- Copper siding: Premium option with unmatched longevity and evolving color.

- Exterior corrugated metal siding: Budget-friendly and industrial-chic; often used on metal clad sheds or accent walls.

Also consider pac clad hwp (high-wall panels) or pac clad column covers if you’re matching existing architectural elements.

4. Step-by-Step Installation Guide

Installing metal clad siding correctly prevents leaks, warping, and premature wear. Follow these steps:

4.1 Prepare the Wall Surface

Ensure your sheathing is flat, dry, and covered with a high-quality weather-resistant barrier (WRB). Use furring strips if needed to create a drainage plane behind the metal—critical for preventing moisture buildup behind a metal clad wall.

4.2 Measure and Cut Panels

Use metal sheet cutting tools like aviation snips or a circular saw with a metal-cutting blade. Always wear safety gear. For precision, mark cuts on aluminum clad sheet or stainless steel metal plate using a straight edge.

4.3 Start at the Bottom

Begin with a level starter strip. For vertical standing seam metal siding, align the first panel plumb. For corrugated styles, overlap panels per manufacturer specs—typically 1–2 corrugations.

4.4 Fasten Properly

Use corrosion-resistant fasteners (stainless or coated). Drive screws into the flat part of corrugated panels—not the crest—to avoid leaks. For standing seam systems like pac clad coping or colorbond standing seam, use hidden clips to allow thermal expansion.

4.5 Seal Joints and Penetrations

Apply butyl tape or compatible sealant at seams, corners, and around windows. Never rely on caulk alone—proper flashing is key.

5. Common Problems and Quick Fixes

Even the best metal clad house can face issues:

- Oil canning (waviness): Caused by over-tightening fasteners or improper panel support. Solution: Reinstall with correct spacing and clip systems.

- Scratches or dents: Touch up with matching paint (for pre-painted systems) or let natural patina develop (for zinc or corten).

- Condensation behind siding: Ensure adequate ventilation and a proper rainscreen gap.

- Galvanic corrosion: Avoid direct contact between dissimilar metals (e.g., aluminum clad steel touching copper). Use isolation tape or coatings.

6. Maintenance Tips for Longevity

Metal clad siding is low-maintenance but not zero-maintenance:

- Rinse annually with water to remove dirt and pollutants.

- Inspect fasteners and seals every 2–3 years.

- For stainless plate or brass metal plate accents, polish occasionally to retain luster.

- Never pressure-wash—use soft brushes to avoid damaging finishes like electroplating gold or chromium plate coatings.

7. Conclusion

Whether you’re building a new metal clad building or re-siding an old home, choosing the right clad metal meaning aligns with both function and form. From corten steel plate accents to pac clad standing seam roofs, metal cladding offers unmatched durability and modern appeal. With proper installation and minimal upkeep, your metal clad house will stand strong—and stylish—for decades.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as How. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.