1. Introduction

In the past 48 hours, global architecture and construction sectors have seen renewed interest in sustainable building envelopes following the unveiling of a new eco-district in Copenhagen featuring extensive use of zinc clad dormers and corten steel facades. This trend underscores the growing demand for durable, low-maintenance, and aesthetically versatile metal clad solutions in both residential and commercial projects. Against this backdrop, understanding what ‘metal clad’ truly means—and how it applies across industries—is more relevant than ever.

The term ‘metal clad’ broadly refers to any material or structure that has been covered or layered with metal for enhanced performance, protection, or visual appeal. Whether used in roofing, siding, electrical systems, or industrial piping, metal cladding serves functional and aesthetic roles. From metal clad wall panels to steel clad buildings and even metal clad electrical wire, the applications are vast and varied.

2. Understanding Metal Clad Meaning and Clad Metal Meaning

At its core, ‘metal clad meaning’ describes a composite material where a base substrate—often steel, aluminum, or another alloy—is bonded with a layer of different metal to combine desirable properties. Similarly, ‘clad metal meaning’ refers to engineered materials created through processes like roll bonding, explosion bonding, or electroplating to achieve corrosion resistance, conductivity, strength, or cost efficiency. Examples include aluminum clad stainless steel, stainless clad aluminum, and titanium clad sheets used in aerospace and chemical processing.

These clad metals are not merely surface-coated; they form metallurgical bonds that ensure long-term integrity. For instance, copper nickel clad or cupro nickel clad materials offer excellent marine corrosion resistance, while 2024 T3 clad and 7075 T6 clad aluminum alloys are standard in aircraft skins due to their high strength-to-weight ratios.

3. Architectural Applications: Metal Clad Buildings and Facades

In architecture, metal clad systems dominate modern design due to their longevity, recyclability, and striking visual impact. A metal clad house often features elements like corrugated steel facade panels, vertical standing seam metal siding, or a zinc metal siding exterior. Popular choices include corten steel siding—prized for its weathering rust patina—and copper siding, which develops a distinctive green verdigris over time.

Standing seam systems, such as colorbond standing seam or PAC CLAD standing seam roof profiles, provide watertight, low-profile roofing ideal for contemporary aesthetics. Similarly, PAC CLAD HWP (horizontal wall panel) systems and PAC CLAD column covers offer seamless integration for commercial facades. The zinc clad roof and zinc clad dormer are increasingly favored for their self-healing oxide layer and minimal maintenance needs.

Notably, corten steel siding cost remains competitive compared to other premium claddings, making corten siding cost an attractive factor for architects seeking dramatic yet economical exteriors. Steel clad buildings, including metal clad sheds and warehouses, leverage corrugated or flat metal steel plate systems for rapid assembly and resilience against extreme weather.

4. Industrial and Technical Uses of Clad Metals

Beyond architecture, clad metals play critical roles in engineering and manufacturing. Aluminum clad steel wire and aluminum clad pipe insulation enhance thermal and electrical performance while reducing weight. Metal clad insulation is widely used in HVAC and cryogenic systems to prevent heat loss and condensation.

In electrical applications, metal clad electrical wire—often referred to as MC cable—is armored for safety in commercial and industrial settings. Cu clad wire (copper-clad) improves conductivity while lowering material costs. Aluminum clad wire is common in power transmission due to its light weight and corrosion resistance.

High-performance alloys like Inconel 625 plate, Inconel 718 plate, and chrome carbide overlay plates are used in extreme environments such as oil refineries and power plants. These materials often feature weld overlays or clad layers to extend service life under high stress, temperature, or abrasion.

5. Common Metal Plates and Sheets in Cladding Systems

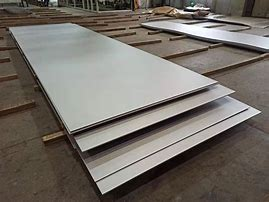

The foundation of many metal clad assemblies lies in standardized metal plates and sheets. Stainless steel plate grades—including 304L, 316, 316L, and 904L—are selected based on corrosion resistance needs. Carbon steel plate, mild steel plate, and boiler plate steel serve structural roles, while specialty items like diamond plate steel, aluminum tread plate, and checker plate metal sheet provide slip resistance for walkways and industrial flooring.

Aluminum alloys such as 5052, 6061-T6, and 7075 are available as aluminum sheet for sale or thick plate forms, often used in marine or transport applications. Perforated plate and metal plate with holes enable acoustic and ventilation functions in facades. Meanwhile, brass plates for engraving and metal nameplates serve identification and decorative purposes.

Prices vary significantly by thickness and alloy—e.g., 1/8 inch steel plate versus 3/16 metal plate—and buyers often search for ‘steel plate near me’ or ‘aluminium checker plate near me’ to source locally. ASTM standards like ASTM A387 govern pressure vessel plates, ensuring reliability in critical applications.

6. Conclusion

Metal clad technologies span from the microscopic scale of electroplating and clad wire to the monumental scale of steel clad buildings and corten steel facades. Whether enhancing durability through chromium electroplating, enabling sleek design with a standing seam facade, or improving efficiency with aluminum clad stainless steel, these materials represent a fusion of engineering ingenuity and aesthetic versatility. As sustainability and resilience drive future construction, metal clad systems will remain at the forefront of innovation across industries.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Metal. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.