1. Introduction

In a major industry development reported just hours ago, global demand for sustainable architectural cladding has surged following the European Union’s new Green Building Directive, which mandates low-carbon exterior materials for all public infrastructure by 2027. This policy shift has intensified interest in durable, recyclable solutions like metal clad systems—sparking renewed focus on materials ranging from corten steel siding to aluminum-clad stainless steel composites.

Metal clad—often interchangeably referenced as metalclad or clad metals—encompasses a broad spectrum of engineered products where two or more metals are bonded to combine desirable properties. While the term ‘metal clad meaning’ generally refers to any structure or component with a metallic outer layer, ‘clad metal meaning’ specifically denotes laminated or bonded metal composites used in industrial contexts. Understanding these distinctions is critical for architects, engineers, and contractors selecting materials for everything from a metal clad house to high-performance piping.

2. Architectural Metal Cladding Systems

2.1. Facade and Roofing Applications

Modern metal facade systems leverage the aesthetic and functional versatility of clad metals. The corten steel facade, prized for its weathering properties and rust-like appearance, offers low maintenance and dramatic visual impact. However, corten steel siding cost remains higher than alternatives, typically ranging from $8 to $15 per square foot installed. In contrast, zinc facade panels provide self-healing patina and longevity exceeding 100 years, while copper siding delivers timeless elegance but at a premium price point.

Standing seam systems dominate commercial roofing, with options like colorbond standing seam and pac clad standing seam roof offering weathertight performance. Vertical standing seam metal siding enhances contemporary aesthetics, while corrugated steel facade and exterior corrugated metal siding evoke industrial charm. For dormers and intricate details, zinc clad dormer elements provide malleability and corrosion resistance unmatched by standard steel.

2.2. Residential Integration

The rise of the metal clad house reflects growing demand for resilience and modern design. Steel clad homes utilize materials like aluminum clad steel or stainless clad aluminum for enhanced durability against fire, pests, and extreme weather. Metal weatherboard and metal clad wall systems mimic traditional wood profiles while eliminating rot and warping. Notably, pac clad column covers and pac clad coping offer seamless transitions between structural and decorative elements.

3. Industrial and Technical Clad Metals

3.1. Composite Metal Plates and Sheets

Beyond architecture, clad metals serve critical roles in chemical processing, energy, and transportation. Aluminum clad stainless steel and stainless clad aluminum merge corrosion resistance with strength-to-weight efficiency. Titanium clad plates protect reactors in aggressive environments, while alloy clad variants like 2024 T3 clad and 7075 T6 clad enhance aerospace performance through tailored surface hardness and fatigue resistance.

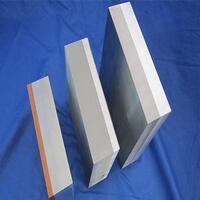

Common base materials include mild steel plate, carbon steel plate, and boiler plate steel, often overlaid via roll bonding or explosion welding. Specialty plates—such as chrome carbide overlay, stainless steel diamond plate, and aluminum diamond tread plate—address wear, slip resistance, and structural reinforcement needs. Thicknesses vary widely, from 1/8 inch steel plate to thick steel plate exceeding 4 inches, with grades like ASTM A387 governing pressure vessel applications.

3.2. Electrical and Insulation Uses

Metal clad electrical wire (e.g., aluminum clad wire, cu clad wire) provides electromagnetic shielding and mechanical protection in commercial settings. Contrary to misconceptions, metal clad wire can be used outside when rated for wet locations and properly sealed. Similarly, aluminum clad pipe insulation combines thermal efficiency with vapor barrier properties, ideal for HVAC and cryogenic systems.

4. Material Comparison and Selection Criteria

Choosing the right metal clad type depends on environment, budget, and performance requirements. Corten siding cost may deter some, but its zero-maintenance lifecycle offsets initial expense. Zinc metal siding outperforms painted steel in coastal zones due to superior salt resistance. For interiors or non-structural uses, aluminum clad sheet or aluminium clad sheet offers lightweight formability.

- Corten steel plate: Best for artistic, low-maintenance exteriors; not suitable for high-humidity enclosed spaces.

- Stainless steel plate grades (e.g., 316L, 904L): Ideal for chemical exposure; higher cost but exceptional longevity.

- Aluminum 5052 sheet and 6061 T6 aluminum plate: Optimal for marine and transport applications due to corrosion and weldability balance.

- Copper nickel clad and cupro nickel clad: Used in desalination and offshore platforms for biofouling resistance.

5. Conclusion

From the sleek lines of a zinc clad roof to the rugged reliability of clad steel in industrial piping, metal clad technologies continue to evolve at the intersection of sustainability, innovation, and performance. As regulations like the EU’s Green Building Directive accelerate adoption, understanding the nuances between metal clad meaning and clad metal meaning—and selecting the appropriate metal clad type—will remain essential for forward-looking design and engineering.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Metal. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.