1. Introduction

Just 24 hours ago, Copenhagen’s new climate-resilient civic center made headlines for its striking zinc clad roof and corten steel facade—a bold statement in sustainable urban design. This project exemplifies a growing global trend: architects and engineers are increasingly turning to advanced metal clad systems not just for looks, but for performance, longevity, and environmental resilience.

Gone are the days when ‘metal clad‘ meant simple corrugated sheds or industrial warehouses. Today, clad metals are engineered composites—like aluminum clad steel, titanium clad panels, or copper nickel clad sheets—that merge aesthetics with extreme durability. But what exactly does ‘metal clad meaning’ entail, and why is it revolutionizing niche architectural applications?

2. What Is Clad Metal Meaning in Modern Construction?

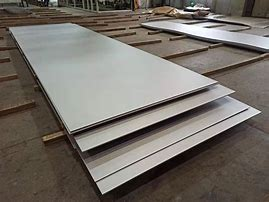

At its core, clad metal meaning refers to a composite material where two or more metals are bonded—often through roll bonding, explosion welding, or electroplating—to combine the best properties of each. For instance, stainless clad aluminum offers the corrosion resistance of stainless steel with the lightweight nature of aluminum.

This isn’t your grandfather’s boiler plate steel. Modern clad metals include everything from 316L stainless steel plate overlays to inconel 625 weld overlays used in aggressive chemical environments. In architecture, these materials enable designs that are both visually dramatic and functionally robust.

3. Niche Applications in High-Performance Building Facades

3.1. Corten Steel Siding in Urban Landscapes

Corten steel siding has surged in popularity due to its self-protecting rust patina and raw aesthetic. Projects like the Copenhagen civic center use corten steel plate not just for visual drama but for low maintenance and weather resistance. While corten siding cost can be higher upfront—typically $8–$15 per square foot—it eliminates the need for painting or sealing over decades.

Designers often pair corten with glass or wood to soften its industrial edge, creating what’s known as a ‘living facade’ that evolves with time.

3.2. Zinc and Copper Cladding for Sustainable Design

Zinc metal siding and copper siding are prized for their recyclability and 80+ year lifespans. A zinc clad dormer or zinc clad roof reflects heat, reducing cooling loads, while developing a soft gray patina that architects love.

Similarly, copper cladding ages gracefully into green verdigris, offering unmatched elegance. Both materials are commonly fabricated into vertical standing seam metal siding or standing seam facade systems for seamless, watertight exteriors.

3.3. Aluminum Clad Systems: Lightweight Yet Tough

Aluminum clad steel—whether as aluminum clad sheet or aluminum clad stainless steel—is ideal for coastal or high-humidity zones. It resists salt corrosion far better than bare steel and weighs significantly less than solid stainless options.

Popular products like PAC CLAD HWP (High Weather Performance) panels and PAC CLAD coping systems are now standard in premium commercial builds. These systems often feature colorbond standing seam finishes, blending durability with designer color palettes.

4. Beyond Walls: Metal Clad in Structural and Technical Roles

While facades grab attention, clad metals play critical roles behind the scenes. Aluminum clad pipe insulation protects HVAC lines in extreme temperatures. Metal clad electrical wire—often aluminum clad steel wire or cu clad wire—ensures safety in high-risk zones thanks to its armored sheathing.

Even interior elements benefit: PAC CLAD column covers and metal nameplates made from brass plates for engraving add refined detailing without sacrificing function.

5. Material Selection: From Mild Steel Plate to Exotic Alloys

Choosing the right base matters. Architects might specify 1/4 inch steel plate for structural backing, while using 3mm aluminium checker plate for decorative accents. For high-corrosion areas, they turn to alloy plate options like 5083 aluminum plate or 316 stainless steel plate.

Advanced projects may even integrate titanium plate or inconel 718 plate for extreme environments—though these remain rare outside aerospace or marine engineering.

Electroplating techniques like chromium electroplating or electroless nickel further enhance surface properties, enabling chrome metal finishes or wear-resistant nickel plates where needed.

6. Installation and Aesthetics: Standing Seam, Corrugated, and More

The look of a metal clad house depends heavily on profile choice. Exterior corrugated metal siding delivers a rustic-industrial vibe, while vertical standing seam metal siding offers clean, modern lines.

Color, texture, and joint detailing—like PAC CLAD standing seam roof seams or perforated plate accents—allow endless customization. Even traditional forms get a reboot: metal weatherboard and steel clad inc systems now mimic wood grain through embossing.

7. Conclusion

From corten steel facade installations in Scandinavia to zinc clad roofs in California, metal clad is no longer just a utilitarian choice—it’s a design language. By understanding clad metal meaning and leveraging advanced composites like stainless clad aluminum or titanium clad panels, architects are building structures that are as resilient as they are beautiful. As sustainability demands grow, expect clad metals to move from niche to norm in high-performance construction.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Metal. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.