1. Introduction

In a major development reported just hours ago, the new Pacific Northwest National Laboratory (PNNL) research facility in Richland, Washington, unveiled its innovative facade system featuring titanium-clad panels and zinc clad dormers designed for extreme weather resilience and energy efficiency. This project exemplifies a growing trend in architecture: the strategic deployment of advanced metal clad systems not merely for aesthetics, but for functional performance in demanding environments.

Metal clad—often interchangeably referred to as metalclad or clad metals—has evolved far beyond basic roofing or siding. Today, architects and engineers specify metal clad wall systems, steel facade elements, and specialty clad composites like aluminum clad stainless steel to meet rigorous standards for durability, thermal performance, and visual identity. Understanding the clad metal meaning is essential: it refers to layered materials where a base metal (like carbon steel) is bonded with a corrosion-resistant or decorative surface layer (such as stainless steel, copper, or zinc).

2. Metal Clad in Contemporary Facade Engineering

Modern building envelopes increasingly rely on metal clad solutions that merge form with function. Unlike traditional cladding, today’s systems are engineered at the molecular and structural level to address climate challenges, reduce lifecycle costs, and achieve net-zero goals.

- Corten steel facade panels offer self-protecting rust patinas that eliminate the need for painting while providing dramatic visual texture; corten steel siding cost remains competitive due to low maintenance requirements.

- Zinc metal siding and zinc clad roof systems provide exceptional longevity—often exceeding 80 years—with natural antimicrobial properties and recyclability.

- Copper siding develops a distinctive green patina over time, valued in heritage-sensitive urban infill projects.

- Aluminum clad steel and stainless clad aluminum composites deliver strength-to-weight advantages ideal for tall buildings and seismic zones.

3. Specialty Applications Driving Innovation

Beyond standard exteriors, niche applications are pushing the boundaries of what metal clad can achieve. For instance, vertical standing seam metal siding is now integrated with photovoltaic cells in building-integrated photovoltaics (BIPV), turning entire facades into power generators. Similarly, pac clad standing seam roofs with pac clad coping and column covers are specified in coastal hospitals for salt-air resistance.

In industrial settings, aluminum clad pipe insulation protects critical infrastructure from thermal loss and corrosion. Meanwhile, metal clad electrical wire—distinct from architectural cladding—is engineered for fire resistance and mechanical protection in data centers and high-rise cores.

Even small components benefit: zinc clad dormers on residential metal clad houses combine heritage aesthetics with modern moisture management. Exterior corrugated metal siding, once relegated to sheds, now appears in luxury homes as corrugated steel facade elements when paired with precision detailing like pac clad hwp trim.

4. Material Science Behind Clad Metals

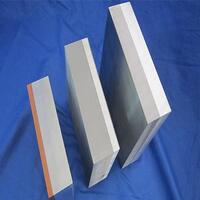

The performance of clad metals stems from advanced bonding techniques. Roll bonding, explosion welding, and co-extrusion create metallurgical bonds between dissimilar metals—such as titanium clad onto steel plate or copper nickel clad layers for marine applications. These processes yield materials like 2024 T3 clad aluminum for aerospace or inconel 625 weld overlay plates for chemical processing.

Common base substrates include mild steel plate, boiler plate steel, and alloy plate (e.g., 6061 T6 aluminum plate or 316 stainless steel plate). Surface layers may involve electroplating (chromium electroplating, electroless nickel) or solid overlays (chrome carbide plate, inconel 625 plate). The result is a hybrid material that leverages the economy of carbon steel with the corrosion resistance of noble metals.

For architectural use, finishes range from diamond plate steel sheets for tactile safety to perforated plate for acoustic control. Colorbond standing seam and pac clad systems offer pre-finished color stability, while bare metals like corten steel plate develop organic finishes over time.

5. Sustainability and Future Outlook

Metal clad building systems contribute significantly to sustainability. Most clad metals are over 90% recyclable, and their longevity reduces replacement frequency. Innovations like aluminum tread plate with recycled content and stainless steel checker plate made from post-consumer scrap further enhance environmental credentials.

As building codes tighten globally, expect wider adoption of metal clad insulation systems that integrate continuous thermal barriers. Digital fabrication also enables custom metal sheet cutting for complex geometries—turning stainless metal sheet or brass plates for engraving into bespoke architectural features.

6. Conclusion

From corten siding cost efficiency to the technical sophistication of titanium clad panels, metal clad has transcended its utilitarian origins. In high-performance architecture, it is no longer just a skin—it is a responsive, resilient, and regenerative component of the built environment. As material science advances and climate pressures intensify, clad metals will remain at the forefront of intelligent building design.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Metal. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.