1. Introduction

Just 24 hours ago, the American Institute of Architects announced the shortlist for its 2024 Innovation in Building Envelope Award—and every finalist prominently features advanced metal clad systems. From self-weathering corten steel facades to titanium-clad structural accents, architects are pushing the limits of what clad metals can do in sustainable, resilient design.

Metal clad isn’t just about durability—it’s becoming a design language. Whether it’s a zinc clad dormer on a mountain lodge or a standing seam facade on a downtown tech hub, these materials merge aesthetics with performance. Let’s dive into how niche applications of metal clad are transforming modern construction.

2. What Is Metal Clad, Really?

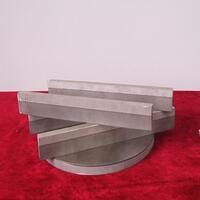

At its core, metal clad meaning refers to a composite material where two or more metals are bonded—often through roll bonding, explosion cladding, or electroplating—to combine the best properties of each. Clad metal meaning? Think stainless clad aluminum for corrosion resistance with lightweight strength, or copper nickel clad for marine environments.

This isn’t just theory. In practice, you’ll find aluminum clad stainless steel in chemical processing plants, titanium clad heat exchangers in aerospace, and even stainless clad aluminum in high-end cookware. But one of the most visible—and rapidly evolving—uses is in architecture.

3. Metal Clad in High-Performance Building Facades

Architects now specify metal clad wall systems not just for looks, but for longevity, thermal performance, and low maintenance. A corten steel facade, for example, develops a protective rust patina that eliminates the need for painting—ideal for remote or hard-to-access installations.

Corten steel siding cost remains higher than standard steel, but lifecycle savings often justify the investment. Similarly, zinc metal siding and copper siding offer natural antimicrobial properties and decades of service life with zero coatings.

- Corten siding cost is offset by zero maintenance over 50+ years

- Zinc clad roof systems resist UV degradation and thermal cycling

- Vertical standing seam metal siding provides clean lines and superior water shedding

4. Beyond Aesthetics: Functional Cladding Systems

It’s not all about the exterior. Metal clad insulation—like aluminum clad pipe insulation—is critical in industrial HVAC and cryogenic applications. The reflective aluminum layer minimizes heat transfer while protecting the underlying foam or fiberglass.

Even in electrical systems, metal clad electrical wire (often called MC cable) is preferred in commercial builds for its armor-like protection. Aluminum clad steel wire and cu clad wire are common in grounding and signal transmission where conductivity and strength must coexist.

And don’t overlook smaller elements: pac clad column covers, pac clad coping, and pac clad hwp (horizontal wall panels) offer seamless integration with main facade systems while protecting structural joints.

5. Material Innovation Driving Adoption

The rise of alloy clad sheets—like 2024 T3 clad aluminum or 7075 T6 clad—brings aerospace-grade performance to architectural details. These materials resist fatigue, corrosion, and extreme temperatures, making them ideal for coastal or high-altitude builds.

Meanwhile, stainless steel plate grades like 316L and 904L are being used as base layers in clad systems for chemical resistance. When paired with a thin layer of titanium or nickel, they create ultra-durable surfaces for labs, hospitals, and clean rooms.

Even classic materials get upgrades: colorbond standing seam roofs now come with nano-coatings that repel dirt, while pac clad standing seam roof panels integrate solar-ready mounting rails without compromising weather-tightness.

6. Real-World Examples You Can See Today

In Denver, a new mixed-use tower uses corrugated steel facade panels over a rainscreen system—combining industrial grit with energy efficiency. In Norway, a public library features a zinc clad dormer that mirrors the surrounding fjord’s color shifts.

Closer to home, steel clad house projects are popping up in wildfire-prone zones. These metal clad buildings use non-combustible exteriors like exterior corrugated metal siding or metal weatherboard to meet strict fire codes without sacrificing style.

And yes—even sheds are getting the treatment. A metal clad shed with aluminum diamond tread plate flooring and stainless steel metal plate brackets can double as a backyard workshop or EV charging station.

7. Choosing the Right Metal Clad Type

Not all clad metals are equal. For roofs, zinc clad roof or colorbond standing seam offers longevity. For coastal salt spray? Go with cupro nickel clad or inconel 625 overlay. Need something lightweight but strong? Aluminum clad steel or aluminium clad sheet might be your answer.

Always consider compatibility. Mixing dissimilar metals without proper isolation can cause galvanic corrosion. That’s why many specifiers now choose pre-engineered systems from firms like Steel Clad Inc., which test full assemblies for real-world performance.

8. Conclusion

Metal clad has moved far beyond basic siding or wiring. In today’s architecture and engineering, it’s a precision tool—blending material science, sustainability, and bold design. Whether you’re specifying a corten steel plate for a sculpture-like entry or aluminum clad pipe insulation for a geothermal loop, clad metals deliver where single-material solutions fall short.

As building codes tighten and climate resilience becomes non-negotiable, expect metal clad systems to keep leading the charge—one standing seam, one zinc facade, one titanium-clad beam at a time.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Metal. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.