1. Introduction

In the past 48 hours, a surge in sustainable building material demand has spotlighted metal clad systems—especially as architects seek durable, low-maintenance exteriors amid global supply chain shifts. With cities like Copenhagen and Toronto mandating climate-resilient facades, metal cladding has moved from niche to mainstream.

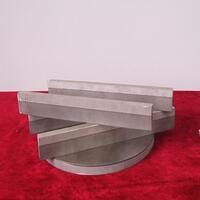

But what exactly does ‘metal clad‘ mean? At its core, metal clad (or clad metals) refers to composite materials where a base metal is bonded—mechanically or metallurgically—with a layer of another metal to enhance performance, corrosion resistance, or aesthetics. This concept spans everything from a metal clad wall on a modern home to high-performance clad steel used in chemical processing plants.

2. Understanding Clad Metal Meaning and Types

The term ‘clad metal meaning’ often confuses newcomers. Simply put, it’s not a single material but a layered system. Common combinations include aluminum clad steel, stainless clad aluminum, and titanium clad substrates. These are created through processes like roll bonding, explosion bonding, or electroplating.

- Aluminum clad stainless steel offers the corrosion resistance of stainless with the lightweight economy of aluminum.

- Copper nickel clad is prized in marine environments for its anti-fouling properties.

- 2024 T3 clad and 7075 T6 clad aluminum alloys are used in aerospace for strength-to-weight ratios.

Industrial applications also rely on specialized forms like metal clad wire (e.g., cu clad wire or aluminum clad steel wire) for electrical conductivity and mechanical durability.

3. Metal Clad in Architecture: Facades, Roofs, and Siding

Architects increasingly specify metal clad systems for their longevity and visual drama. A metal clad house today might feature corten steel siding for its rusted elegance or a zinc facade for its self-healing patina.

Popular choices include:

- Corten steel facade: Known for weathering naturally; corten steel siding cost ranges from $8–$15/sq.ft., making it a premium but low-maintenance option.

- Zinc clad roof and zinc clad dormer: Elegant, recyclable, and lasting 80+ years.

- Colorbond standing seam and PAC Clad standing seam roof systems: Offer clean lines with vertical standing seam metal siding for modern aesthetics.

- Exterior corrugated metal siding and corrugated steel facade: Industrial-chic look with structural rigidity.

Copper siding and zinc metal siding provide timeless appeal, while PAC Clad coping and column covers add refined detailing to metal clad buildings.

4. Performance Comparison: Steel, Aluminum, Zinc, and Corten

Not all metal clad types perform equally. Steel clad (often using mild steel plate or corten steel plate) offers strength but requires protective coatings unless using weathering grades like ASTM A387.

Aluminum clad sheet (including 6061 T6 aluminum plate or 5052 aluminum plate) resists corrosion and weighs less—ideal for cladding tall structures. Aluminum diamond tread plate is also used for functional accents like stair treads on metal clad sheds.

Zinc and nickel alloy claddings provide superior atmospheric resistance, while stainless steel plate grades (316, 316L, 304L) dominate in high-corrosion zones. Stainless clad aluminum merges the best of both but at higher cost.

For budget-conscious projects, exterior corrugated metal siding over a steel base plate remains popular, though it lacks the longevity of premium options like titanium clad or inconel 625 overlay systems.

5. Industrial and Electrical Uses of Metal Clad Systems

Beyond architecture, metal clad meaning extends to critical infrastructure. Metal clad electrical wire—often aluminum clad wire or armored metal clad cable—is used in commercial buildings (including in Pennsylvania, where code permits) for fire and impact resistance.

Aluminum clad pipe insulation protects HVAC and process lines, while metal clad insulation wraps ducts in energy-efficient designs.

In manufacturing, clad metals like chrome carbide plate or boiler plate steel with nickel sulfamate coatings handle extreme wear. Diamond plate steel sheets and perforated plate variants serve both safety and filtration roles.

Even niche items like brass plates for engraving or bronze plate price-per-kg calculations factor into custom metal nameplates or heritage restoration using clad techniques.

6. Cost, Availability, and Trends

Steel plate price fluctuations directly affect clad steel affordability. While 1/8 inch steel plate or 3/16 metal plate is widely available (‘steel plate near me’ searches spike during construction seasons), exotic alloys like inconel 718 plate or titanium alloy plate remain costly.

However, rising demand for sustainable materials is driving innovation. Recycled-content aluminum clad sheet and PAC Clad HWP (high-performance) products now offer greener alternatives without sacrificing durability.

7. Conclusion

Whether you’re designing a steel clad house, specifying a corten steel facade, or selecting metal clad wire for an industrial site, understanding the nuances of clad metals is essential. From the meaning of metal clad to real-world performance across zinc, aluminum, steel, and specialty alloys, the right choice balances cost, climate, and creativity. As building codes evolve and sustainability takes center stage, metal clad systems will only grow in relevance and versatility.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Metal. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.