-

Nickel-based Alloy Composite Plate

High quality 99.995% nickel sheet nickel sheet scrap nickel sheet

-

Nickel-based Alloy Composite Plate

Customizable Bulk battery nickel sheet 18650 Copper-nickel composite busbar Copper-nickel battery connection sheet

-

Nickel-based Alloy Composite Plate

Custom 18650 Copper 18650 21700 Busbars Nickel Plated Copper Sheet 18650 Battery Copper Nickle Busbar Sheet

-

Nickel-based Alloy Composite Plate

S355j0 1020 1045 1010 1012 1050 1060 50mn Ck45 8mm Stainless/Roofing/Mild/Alloy/Nickel/Aluminum/Carbon Steel Sheet

-

Nickel-based Alloy Composite Plate

Block Neodymium Magnet Disc NdFeB Rare Earth Industrial Permanent Cylinder Cup Gold/Nickel Coating Models N42 N50 N48 Bending

-

Nickel-based Alloy Composite Plate

High Precision Pure Nickel Plated Tinned Copper Strip Silver Copper Bimetal Strip Rolled Copper Foil Tape for battery pack 18650

-

Nickel-based Alloy Composite Plate

China Factory NiCr Alloy Cr20Ni80 Cr30Ni70 Cr15Ni60 With Chemical Composition Ni-Cr Heating Resistance Nickel Wire for Industry

-

Nickel-based Alloy Composite Plate

OEM 18650 copper + nickel composite connector nickel strip welding nickel brass sheet

-

Nickel-based Alloy Composite Plate

Customizable Battery Nickel Sheet Battery Connector 18650/21700 Copper-nickel Composite Copper-nickel Busbar OEM

-

Nickel-based Alloy Composite Plate

Custom 6S8P 18650 21700 32650 Power Lithium Battery Connector Busbar Copper Nickel Copper Nickel Sheet

-

Nickel-based Alloy Composite Plate

nickel moisture lump composition nickel ore with supply ability 1000000 metric tons per week 18650 pure nickel strip

-

Nickel-based Alloy Composite Plate

High Quality Monel 400 Sheet Nickel Based Alloy Plate

Nickel-based Alloy Composite Plate

Overview of Nickel-based Alloy Composite Plate

Nickel-based alloy composite plates are advanced materials designed for applications requiring exceptional corrosion resistance, high-temperature stability, and superior mechanical properties. These plates consist of a nickel-based alloy bonded to a substrate material, typically for enhanced performance in harsh environments.

Features of Nickel-based Alloy Composite Plate

Nickel Alloy Type: Nickel-based alloys can vary, with common types including Inconel, Monel, Hastelloy, and Incoloy, each tailored for specific properties such as high-temperature resistance, corrosion resistance, or strength.

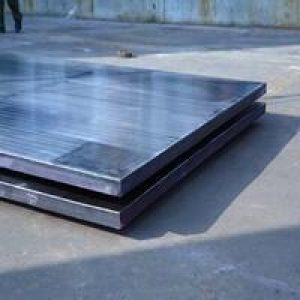

Substrate Material: The substrate provides the bulk of the composite’s structure, often aluminum, steel, or composite materials like fiber-reinforced plastics, chosen for its mechanical properties or cost-effectiveness.

Bonding Process: The method used to adhere the nickel alloy layer to the substrate can be explosion bonding, hot rolling, or cladding, affecting the bond strength and uniformity.

Thickness: The thickness of both the nickel alloy layer and the substrate are specified, with the alloy layer typically thinner to maximize cost-effectiveness while maintaining surface protection.

Dimension: Available in standard or custom sizes, dimensions refer to the plate’s length, width, and overall thickness, tailored to application requirements.

Surface Finish: The surface of the nickel alloy layer can be polished, brushed, or left as-milled, depending on the need for aesthetics or specific functional requirements.

Corrosion Resistance: A critical parameter, often quantified by testing methods like salt spray tests, indicating the alloy’s ability to resist corrosion in various environments, including acidic, alkaline, or high-salinity conditions.

High-Temperature Performance: Nickel-based alloys are known for their ability to retain strength and resist oxidation at elevated temperatures, with performance parameters including creep resistance and thermal expansion coefficients.

Mechanical Properties: Tensile strength, yield strength, elongation, and hardness are key indicators of the composite plate’s ability to withstand mechanical stresses.

Weldability and Formability: The ease with which the composite plate can be welded or formed into complex shapes is important for fabrication and installation, influenced by the choice of substrate and bonding process.

Heat Treatment: In some cases, heat treatment after bonding may be required to optimize the properties of the nickel alloy layer or improve the bond interface.

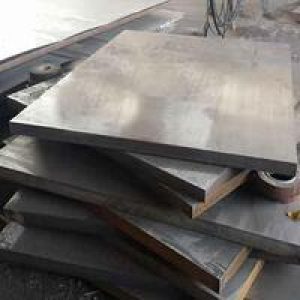

Parameters and specifications of nickel-based alloy composite plates

Thickness: The overall thickness is generally between 5mm and 100mm, depending on the needs of the application scenario.

Width and length: It can be customized according to customer requirements. The common width range is 1000mm to 3000mm, and the length is more flexible.

Alloy composition: The nickel-based alloy part mainly contains elements such as nickel (Ni), chromium (Cr), and molybdenum (Mo). The proportion of these elements will affect the corrosion resistance, strength and other properties of the plate.

Bond strength: The bonding strength between the nickel-based alloy and the substrate is a key indicator. High-quality nickel-based alloy composite plates can provide a bonding strength of more than 200MPa.

Application of nickel-based alloy composite plates

Chemical industry: used to manufacture equipment such as reactors and storage tanks, especially when dealing with highly corrosive media.

Oil and gas industry: suitable for key components involving high-corrosion environments in offshore platforms and refineries.

Power industry: used for boiler piping systems, heat exchangers, etc. to improve the corrosion resistance of equipment.

Desalination and marine engineering: Due to its excellent seawater corrosion resistance, it is suitable for desalination equipment and marine engineering structures.

Company Profile

Metal Plates 4u is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of nickel-based alloy clad plates

Q: What are the main advantages of nickel-based alloy clad plates?

A: The main advantage is that it combines the excellent corrosion resistance of nickel-based alloys with the cost-effectiveness of base materials, achieving the best balance between performance and cost.

Q: How to choose a suitable nickel-based alloy clad plate?

A: The required alloy composition and plate specifications are determined according to the specific use environment, such as temperature, pressure, corrosive media and other factors.

Q: Can nickel-based alloy clad plates be welded?

A: Yes, but specific welding process specifications need to be followed to ensure that their corrosion resistance and bonding strength are not affected.

Q: Is it more economical to use nickel-based alloy clad plates than pure nickel-based alloys?

A: In most cases, the answer is yes, because the amount of expensive nickel-based alloys is reduced while maintaining the necessary performance.

Q: What is the service life of nickel-based alloy clad plates?

A: This depends on the specific conditions of use, but with proper maintenance, its service life can be very long, especially in corrosive environments.