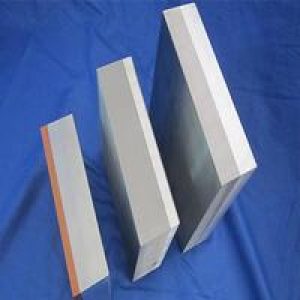

Overview of Stainless Steel Composite Panel

Stainless steel composite panels (SSCP) are modern building materials combining the durability and aesthetics of stainless steel with the lightweight properties of composite substrates. These panels are extensively used in exterior cladding, interior decoration, partitions, and signage due to their versatility and resistance to weathering and corrosion.

Features of Stainless Steel Composite Panel

Surface Finish: The outer stainless steel layer can have various finishes, including mirror polish, hairline (brushed), vibration (stippled), bead blast, or customized patterns, influencing the panel’s visual appeal and maintenance requirements.

Core Material: The composite core is typically made of aluminum honeycomb, polyethylene (PE), or other plastic materials, providing stiffness and lightness. The choice of core affects panel strength, insulation properties, and fire resistance.

Thickness: The total thickness of the panel includes the stainless steel skin and the composite core. Thicknesses can range from 4mm to 20mm or more, depending on the application’s structural and aesthetic requirements.

Dimension: Panels are usually produced in standard sizes or cut to custom dimensions. Common sizes may range from 1220mm x 2440mm to larger formats like 1500mm x 3000mm, with tolerances specified by manufacturers.

Color and Pattern: Stainless steel can be colored through processes like PVD (Physical Vapor Deposition) or coating, offering a wide range of colors beyond the natural silver finish. Patterns can also be embossed onto the surface.

Adhesive: The bond between the stainless steel skin and the composite core is crucial. High-quality adhesives ensure the panel’s structural integrity and resistance to delamination over time.

Fire Resistance: Depending on the core material and overall composition, SSCP can be designed to meet various fire rating standards, making them suitable for buildings with strict fire safety codes.

Bending Radius: The minimum radius to which the panel can be bent without cracking or de-laminating is an important parameter for designing curved surfaces or complex architectural features.

Weather Resistance: Stainless steel inherently offers excellent resistance to corrosion and UV degradation, ensuring the panels maintain their appearance and performance over extended outdoor exposure.

Installation System: SSCP require specialized fixing systems, such as invisible clips, rivets, or bonding agents, which should be compatible with the panel’s weight, size, and intended use, ensuring secure and aesthetically pleasing installation.

Parameters and specifications of stainless steel alloy plates

Thickness: usually ranges from 0.3mm to 60mm, depending on the application requirements.

Width: generally between 1000mm and 2000mm, but there are also special customized sizes.

Length: can be supplied in fixed length or coil form as needed.

Material grade: such as 304, 316, 430, etc., different grades are suitable for different environments and uses.

Surface treatment: including but not limited to polished surface, frosted surface, pickled surface, etc.

Application of stainless steel alloy plates

Architectural decoration: used for curtain walls, elevator decoration, interior decoration, etc. of buildings.

Kitchen equipment: making sinks, stove tops, refrigerator shells, etc.

Chemical industry: due to its excellent corrosion resistance, it is often used in chemical containers, pipes, etc.

Medical equipment: surgical instruments, medical equipment cabinets, etc., because stainless steel is easy to clean and disinfect.

Food processing equipment: manufacturing food-grade workbenches, storage tanks, conveyor belts, etc.

Company Profile

Metal Plates 4u is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs about Stainless Steel Alloy Plates

How to choose the right stainless steel alloy plate for you?

Mainly consider the use environment (such as whether it is exposed to corrosive substances), the required strength, the budget, and the appearance requirements to choose the right material grade and surface treatment.

Why do some stainless steels rust?

Despite the name “stainless steel”, some types of stainless steel may rust in certain environments (such as chlorine-containing environments). Choosing the right type of stainless steel is crucial to avoid this.

What are the advantages of stainless steel alloy plates compared to carbon steel plates?

Stainless steel has better corrosion resistance, better appearance and low maintenance costs; while carbon steel is more economical under high strength requirements.

How to maintain the surface of stainless steel?

Clean regularly with mild detergent and water, wipe dry with a soft cloth, and avoid using detergents containing chlorides to prevent corrosion.

What are the price factors of stainless steel alloy plates?

The price is affected by many factors, including raw material costs, production process complexity, market supply and demand conditions, and specific specification requirements.