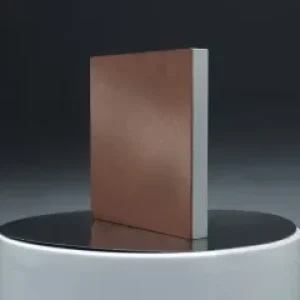

Overview of 3mm 4mm Alucobond Aluminum Composite Panel Alucobond

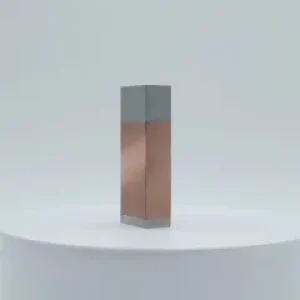

3mm 4mm Alucobond Aluminum Composite Panel Alucobond is an innovative building material consisting of two outer metal skins bonded to a solid thermoplastic core. This engineered structure creates a lightweight, flat, and rigid panel ideal for modern architectural cladding and signage, offering superior durability and a sleek aesthetic finish.

Features of 3mm 4mm Alucobond Aluminum Composite Panel Alucobond

- Lightweight & High Strength: Exceptional strength-to-weight ratio for easier handling and reduced structural load.

- Excellent Flatness: Maintains a smooth, unwavering surface for a flawless appearance.

- Superior Weather Resistance: Resists corrosion, fading, and weathering for long-lasting performance.

- Versatile Formability: Can be curved, bent, and shaped to meet diverse design requirements.

- Wide Range of Finishes: Available in various colors, metallic coatings, and textures (e.g., PVDF, PE, Anodized).

Applications of 3mm 4mm Alucobond Aluminum Composite Panel Alucobond

- Architectural Cladding: Exterior façades, curtain walls, and rainscreen systems for commercial and residential buildings.

- Interior Design: Feature walls, ceilings, column covers, and retail displays.

- Signage & Branding: Durable and visually striking signage for businesses and infrastructure.

- Industrial Design: Used in fabrication for machine panels, clean rooms, and decorative surfaces.

(3mm 4mm Alucobond Aluminum Composite Panel Alucobond )

Specification of 3mm 4mm Alucobond Aluminum Composite Panel Alucobond

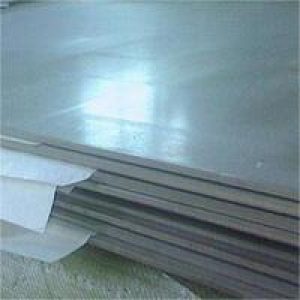

The 3mm and 4mm Alucobond light weight aluminum composite panels are extensively utilized in structure and style. These panels have 2 thin light weight aluminum sheets bonded to a polyethylene core. The total thickness is either 3 millimeters or 4 millimeters. The light weight aluminum skin on each side is typically 0.3 mm or 0.5 mm thick, depending upon the panel kind. This structure provides the panel stamina while maintaining it light.

Alucobond panels been available in several shades and coatings. You can select from solid colors, metal appearances, or brushed impacts. The surface area is covered with PVDF or polyester paint. This finishing secures versus weather condition, UV rays, and deterioration. It also maintains the color looking fresh for years.

These panels are easy to reduce, flex, and mount. They function well for exteriors, signage, interior wall surfaces, and ceilings. Because they are lightweight, they reduce the tons on supporting frameworks. Their flatness and uniform look make them perfect for modern-day architecture.

Fire efficiency is a vital feature. Criterion Alucobond utilizes a polyethylene core, which appropriates for many applications. There are additionally fire-retardant variations with a mineral-filled core. These satisfy more stringent security standards where required.

The panels withstand wetness and do not corrosion. They manage temperature modifications without deforming. Maintenance is straightforward– simply clean with water and light soap. No special treatments are called for.

Alucobond is made to stringent quality assurance. Each set meets global requirements for toughness and performance. The product corresponds in color and dimension. This makes sure smooth installation and an expert surface on every project.

(3mm 4mm Alucobond Aluminum Composite Panel Alucobond )

Applications of 3mm 4mm Alucobond Aluminum Composite Panel Alucobond

3mm and 4mm Alucobond light weight aluminum composite panels are widely used in modern construction and style. These panels incorporate 2 slim light weight aluminum sheets with a polyethylene core. This framework makes them solid yet light-weight. Home builders and developers select them for lots of factors. They resist climate well and last a long period of time. They likewise come in lots of shades and coatings.

One usual usage is for constructing frontages. The panels offer structures a clean, smooth look. They handle sunlight, rain, and wind without fading or bending. This makes them perfect for outdoor walls. They are additionally very easy to mount, which conserves time and labor prices.

Signage is another big application. Business utilize these panels for store signs, signboards, and directional markers. The surface holds printed graphics plainly. It stays intense and legible for years. The product cuts and forms quickly, so custom indicators are basic to make.

Inside buildings, the panels function well for indoor wall surfaces, ceilings, and dividings. They include a streamlined, contemporary feel to lobbies, offices, and retail rooms. Their smooth surface area is easy to clean. They do not gather dust or discolorations easily.

Trade shows and exhibitions likewise rely upon Alucobond panels. Booths and screens constructed with them look specialist and stick out. The panels are light enough to move yet strong enough to hold up during occasions. They can be reused often times.

Transport layout makes use of these panels as well. They appear in buses, trains, and flight terminal interiors. Their lightweight helps reduce gas use. At the very same time, they provide longevity and a sleek appearance.

Alucobond panels in 3mm and 4mm densities satisfy various requirements. The 3mm variation suits lighter tasks like signs and interior use. The 4mm type manages heavier outdoor jobs better. Both sizes offer dependability, design, and convenience of use throughout lots of fields.

Company Profile

Metal Plate 4 U is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Metal Composite Panel Products

1. What is the core material made of?

Typically, the core is made from low-density polyethylene (PE) or a fire-retardant mineral core for enhanced safety ratings.

2. Are these panels suitable for exterior use?

Yes, when manufactured with appropriate coatings like PVDF, they are highly durable and weather-resistant for exterior cladding.

3. How are the panels installed?

They are installed using specialized rivet or clip systems onto a substructure, following manufacturer guidelines for secure mounting.

4. Can the panels be curved?

Absolutely. Their composite nature allows for cold bending to create curved architectural features.

5. How do you clean and maintain them?

Easy maintenance typically requires only occasional washing with water and a mild, non-abrasive detergent.

5 FAQs of 3mm 4mm Alucobond Aluminum Composite Panel Alucobond

What is Alucobond aluminum composite panel?

Alucobond is a type of sandwich panel made of two thin aluminum sheets bonded to a plastic core. The 3mm and 4mm versions refer to the total thickness of the panel. These panels are lightweight yet strong, and they are often used for building facades, signage, and interior walls.

Why choose 3mm or 4mm thickness?

The 3mm panel is lighter and easier to handle, making it good for indoor use or light outdoor applications. The 4mm panel offers more rigidity and better resistance to wind and weather, so it is preferred for exterior cladding on tall buildings or areas with harsh conditions.

Is Alucobond fire resistant?

Standard Alucobond has a polyethylene core, which is not fireproof. However, fire-retardant or non-combustible versions are available with special cores that meet strict safety codes. Always check the product rating if fire safety is a concern.

How long does Alucobond last outdoors?

With proper installation and maintenance, Alucobond panels can last 15 to 20 years or more in outdoor settings. The surface is coated with a protective layer that resists fading, chalking, and corrosion from sun, rain, and pollution.

Can Alucobond be cut and shaped easily?

Yes. Alucobond can be cut, bent, and formed using standard woodworking or metalworking tools. It holds its shape well after bending and allows for creative designs without cracking or delaminating. This makes it popular among architects and fabricators for custom projects.

(3mm 4mm Alucobond Aluminum Composite Panel Alucobond )