Overview of Copper-Coated Straight Steel Fiber Anti-Corrosion Carbon Steel Building Material for Modern Floor Wall School Workshop

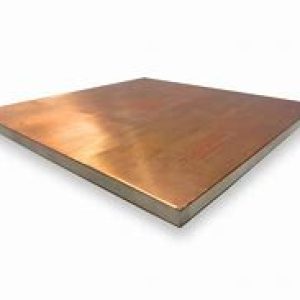

Copper-Coated Straight Steel Fiber Anti-Corrosion Carbon Steel Building Material for Modern Floor Wall School Workshop is an innovative building material that seamlessly bonds a copper veneer to a robust steel core. This fusion creates a panel that combines the timeless, elegant aesthetic of copper with the exceptional strength and durability of steel. It is engineered for high-performance architectural cladding and signage, offering a premium, long-lasting solution for modern construction and design projects.

Features of Copper-Coated Straight Steel Fiber Anti-Corrosion Carbon Steel Building Material for Modern Floor Wall School Workshop

- Dual-Material Advantage: Marries the classic, evolving patina of copper with the structural rigidity and impact resistance of steel.

- Lightweight & Easy to Install: Significantly lighter than solid copper or steel plates, simplifying handling and reducing structural support costs.

- Exceptional Flatness: The composite construction ensures a consistently smooth, ripple-free surface for a flawless appearance.

- Weather & Corrosion Resistance: Offers outstanding durability against the elements, with the copper surface providing natural protective oxidation over time.

- Flexible Fabrication: Can be easily cut, bent, and shaped to meet complex architectural designs and custom specifications.

Applications of Copper-Coated Straight Steel Fiber Anti-Corrosion Carbon Steel Building Material for Modern Floor Wall School Workshop

Ideal for exterior and interior applications where beauty and resilience are paramount. Common uses include:

- Architectural facades, cladding, and curtain walls

- Soffits, canopies, and column covers

- High-end interior feature walls and accents

- Durable and distinctive signage and branding elements

- Renovation projects for a modern, premium upgrade

(Copper-Coated Straight Steel Fiber Anti-Corrosion Carbon Steel Building Material for Modern Floor Wall School Workshop)

Parameters of Copper-Coated Straight Steel Fiber Anti-Corrosion Carbon Steel Building Material for Modern Floor Wall School Workshop

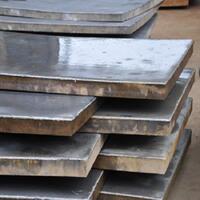

Copper-coated straight steel fiber is a solid structure product produced contemporary floors, walls, and structures like institutions or workshops. It uses carbon steel as its base and obtains a slim layer of copper on the surface. This copper finish assists quit rust and maintains the steel from wearing away over time. The fibers are right, not bent or connected, that makes them simple to blend right into concrete equally.

Each fiber is typically 13 to 60 millimeters long. The size ranges from 0.15 to 0.35 millimeters. These sizes assist the fibers bond well with concrete and add stamina without clumping with each other. The tensile stamina is high, usually above 1000 megapascals, so the fibers can handle hefty lots and stress.

This product works well in places that require lasting floorings or walls. Schools and workshops utilize it since it minimizes cracking and boosts resilience. The copper layer likewise boosts electric conductivity a little, which can be beneficial in some structure layouts.

You can add these fibers directly right into the concrete mix throughout pouring. They spread out smoothly and do not need special tools. The result is a harder surface that withstands wear, impact, and shrinkage splits. Contractors such as this item because it saves time and lower future fixings.

Storage space is simple. Maintain the fibers completely dry and away from moisture before use. The copper finish stays reliable as long as the material is managed appropriately. This steel fiber meets common building criteria and suits both indoor and outdoor tasks. It provides reliable performance without extra steps or expense.

(Copper-Coated Straight Steel Fiber Anti-Corrosion Carbon Steel Building Material for Modern Floor Wall School Workshop)

Applications of Copper-Coated Straight Steel Fiber Anti-Corrosion Carbon Steel Building Material for Modern Floor Wall School Workshop

Copper-coated straight steel fiber is a solid building material made from carbon steel. It has a slim layer of copper on the surface. This finish assists stop corrosion and maintains the steel from rusting. Contractors utilize this product in floorings, walls, and various other parts of contemporary frameworks. It functions well in institutions, workshops, and similar buildings where resilience matters.

The steel fibers blend into concrete or mortar throughout construction. They aid hold the combination together. This makes the final structure harder and much less most likely to break. The copper layer adds extra protection versus dampness and chemicals. That is very important in position like college labs or workshop floorings where spills take place usually.

This product additionally boosts safety and security. Floorings with steel fibers withstand wear and tear much better. Walls stay stronger over time. The fibers do not bend or break conveniently. They maintain their form throughout blending and pouring. This offers building contractors consistent outcomes every time.

Using copper-coated steel fiber minimizes long-lasting repair work costs. Since the material resists deterioration, it lasts longer than routine steel fibers. Institutions and workshops gain from lower upkeep demands. The structures remain secure and useful for several years.

Setup is basic. Employees include the fibers to the concrete mix much like other additives. No special tools or training are needed. The copper covering does not influence how the fibers blend in. Everything mixes evenly and sets as anticipated.

Building contractors choose this product due to the fact that it incorporates stamina, security, and ease of usage. It fulfills modern-day requirements for building materials. It executes well in both indoor and exterior setups. The copper finish likewise offers a tidy look that fits well in brand-new structures.

Company Profile

Metal Plate 4 U is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Copper Steel Composite Panel

1. How does the patina (weathering) of the copper surface affect the panel?

The natural patina formation is a desirable feature, creating a beautiful, protective layer that enhances corrosion resistance and adds character over time. The rate can vary based on local environmental conditions.

2. Is the panel suitable for coastal or high-humidity environments?

Yes. The inherent properties of copper and the protective coating on the steel core provide excellent resistance to salt spray and moisture, making it a suitable choice for such applications.

3. Can the panels be curved or formed into specific shapes?

Absolutely. The composite construction allows for good formability. Panels can be cold-curved or fabricated into various shapes to meet specific design requirements.

4. What are the installation and maintenance requirements?

Installation follows standard practices for composite panels using appropriate mechanical fixing systems. Maintenance is minimal, typically requiring only occasional cleaning with water and a mild detergent.

5. How does the cost compare to solid copper panels?

Copper Steel Composite Panels offer a considerable cost advantage over solid copper, providing the same prestigious look with reduced material weight, easier installation, and often lower overall project costs.

5 FAQs of Copper-Coated Straight Steel Fiber Anti-Corrosion Carbon Steel Building Material for Modern Floor Wall School Workshop

What is copper-coated straight steel fiber?

It is a thin steel wire with a copper layer on the surface. Builders mix it into concrete to make floors and walls stronger. The copper helps stop rust and keeps the steel working well over time.

Why use copper coating on steel fibers?

Copper protects the steel from moisture and air. This stops corrosion, especially in places like schools or workshops where humidity or chemicals may be present. Without this coating, regular steel fibers could rust and weaken the structure.

How does this fiber improve concrete?

When added to concrete, the fibers hold the material together even after cracks start. This makes floors and walls less likely to break under heavy use. It also reduces the need for extra steel mesh or rebar in some cases.

Is it safe for use in schools and public buildings?

Yes. The material meets standard building safety rules. It does not release harmful substances. Its anti-corrosion feature ensures long-term durability, which is important for high-traffic areas like classrooms or hallways.

How is it installed in construction?

Workers mix the fibers directly into wet concrete before pouring. No special tools are needed. The fibers spread evenly and bond well with the cement. This makes the process simple and fast compared to laying traditional reinforcement.

This product works well for modern floor and wall systems. It gives strong support while resisting rust. That makes it a smart choice for schools, workshops, and other busy buildings.

(Copper-Coated Straight Steel Fiber Anti-Corrosion Carbon Steel Building Material for Modern Floor Wall School Workshop)