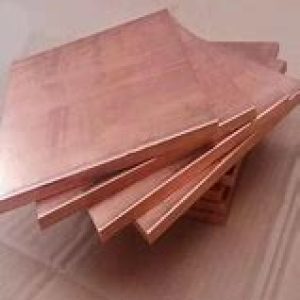

Overview of Copper Steel Clad Plate Roll Bonded Stainless Steel Cladded Sheet Carbon Steel Composite Metal Panel Hot Bonding Plate

Copper Steel Clad Plate Roll Bonded Stainless Steel Cladded Sheet Carbon Steel Composite Metal Panel Hot Bonding Plate is an innovative building material that seamlessly bonds a copper veneer to a robust steel core. This fusion creates a panel that combines the timeless, elegant aesthetic of copper with the exceptional strength and durability of steel. It is engineered for high-performance architectural cladding and signage, offering a premium, long-lasting solution for modern construction and design projects.

Features of Copper Steel Clad Plate Roll Bonded Stainless Steel Cladded Sheet Carbon Steel Composite Metal Panel Hot Bonding Plate

- Dual-Material Advantage: Marries the classic, evolving patina of copper with the structural rigidity and impact resistance of steel.

- Lightweight & Easy to Install: Significantly lighter than solid copper or steel plates, simplifying handling and reducing structural support costs.

- Exceptional Flatness: The composite construction ensures a consistently smooth, ripple-free surface for a flawless appearance.

- Weather & Corrosion Resistance: Offers outstanding durability against the elements, with the copper surface providing natural protective oxidation over time.

- Flexible Fabrication: Can be easily cut, bent, and shaped to meet complex architectural designs and custom specifications.

Applications of Copper Steel Clad Plate Roll Bonded Stainless Steel Cladded Sheet Carbon Steel Composite Metal Panel Hot Bonding Plate

Ideal for exterior and interior applications where beauty and resilience are paramount. Common uses include:

- Architectural facades, cladding, and curtain walls

- Soffits, canopies, and column covers

- High-end interior feature walls and accents

- Durable and distinctive signage and branding elements

- Renovation projects for a modern, premium upgrade

(Copper Steel Clad Plate Roll Bonded Stainless Steel Cladded Sheet Carbon Steel Composite Metal Panel Hot Bonding Plate)

Parameters of Copper Steel Clad Plate Roll Bonded Stainless Steel Cladded Sheet Carbon Steel Composite Metal Panel Hot Bonding Plate

Copper steel outfitted plate is a composite metal panel made by bonding copper and steel with each other. This item uses the roll bonding method, which joins both steels under high pressure and heat. The outcome is a solid, sturdy sheet that maintains the most effective qualities of both materials. Copper supplies good electrical and thermal conductivity, while steel offers strength and structural support.

Stainless steel cladded sheet is an additional kind of composite panel. It integrates stainless steel with carbon steel through hot bonding. The stainless-steel layer stands up to deterioration and looks clean, and the carbon steel base includes durability and lowers expense. This makes the material ideal for use in chemical plants, food processing, and building and construction where both longevity and health issue.

Carbon steel composite steel panels are constructed for sturdy applications. They frequently serve as a core layer in multi-metal sheets. The hot bonding process makes sure a solid bond between layers without gaps or vulnerable points. This technique functions well for large-scale manufacturing and customized dimensions.

All these cladded items share essential functions. They conserve money by using more economical base metals while keeping the surface performance of more expensive alloys. They likewise minimized maintenance because the external layer safeguards versus rust and wear. Manufacture is very easy– they can be cut, curved, and bonded like routine steel sheets.

The bonding top quality is inspected carefully. Tests include ultrasonic assessment to discover any kind of unbonded areas. Criteria adhere to international standards to assure integrity. Density, size, and length can be adjusted based upon consumer requirements. Surface area coating alternatives include pickled, brushed, or mill coating relying on completion use.

These composite plates fit lots of industries. Instances include warm exchangers, stress vessels, storage tanks, and architectural panels. Their mix of performance, expense savings, and simplicity of use makes them a clever choice for designers and designers.

(Copper Steel Clad Plate Roll Bonded Stainless Steel Cladded Sheet Carbon Steel Composite Metal Panel Hot Bonding Plate)

Applications of Copper Steel Clad Plate Roll Bonded Stainless Steel Cladded Sheet Carbon Steel Composite Metal Panel Hot Bonding Plate

Copper steel dressed plate is a composite metal made by bonding copper and steel together. This material keeps the good attributes of both steels. Copper offers strong electrical and thermal conductivity. Steel includes toughness and resilience. The bond between them is strong because it is made using hot roll bonding. This procedure warms the steels and rolls them under high stress. The outcome is a limited, consistent joint that will certainly not separate during usage.

People use this clad plate in several industries. In electric design, it works well for busbars and basing systems. It lugs present effectively while staying strong. In warm exchangers, the copper side relocates heat fast, and the steel side manages stress and structure. Chemical plants also use it since it stands up to corrosion better than plain carbon steel. The copper layer shields versus specific chemicals, and the steel base keeps expenses lower than utilizing all copper.

Stainless steel cladded sheet is an additional typical kind. It joins stainless steel with carbon steel. Stainless-steel uses rust resistance. Carbon steel provides mechanical support at a reduced price. These sheets are used in containers, pipes, and vessels where just part of the surface area needs to stand up to deterioration. That conserves cash without losing performance.

Hot bonding makes certain the layers stick well. No glue or finishing is required. The steels fuse at the atomic level. This implies the plate can be cut, bent, or welded like routine steel. It will not peel off or crack under typical problems. Producers like it since it works with typical devices. Developers choose it when they require a mix of homes that steel alone can not offer. The final product lasts longer and does better in challenging atmospheres.

Company Profile

Metal Plate 4 U is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Copper Steel Composite Panel

1. How does the patina (weathering) of the copper surface affect the panel?

The natural patina formation is a desirable feature, creating a beautiful, protective layer that enhances corrosion resistance and adds character over time. The rate can vary based on local environmental conditions.

2. Is the panel suitable for coastal or high-humidity environments?

Yes. The inherent properties of copper and the protective coating on the steel core provide excellent resistance to salt spray and moisture, making it a suitable choice for such applications.

3. Can the panels be curved or formed into specific shapes?

Absolutely. The composite construction allows for good formability. Panels can be cold-curved or fabricated into various shapes to meet specific design requirements.

4. What are the installation and maintenance requirements?

Installation follows standard practices for composite panels using appropriate mechanical fixing systems. Maintenance is minimal, typically requiring only occasional cleaning with water and a mild detergent.

5. How does the cost compare to solid copper panels?

Copper Steel Composite Panels offer a considerable cost advantage over solid copper, providing the same prestigious look with reduced material weight, easier installation, and often lower overall project costs.

5 FAQs of Copper Steel Clad Plate Roll Bonded Stainless Steel Cladded Sheet Carbon Steel Composite Metal Panel Hot Bonding Plate

What is copper steel clad plate?

It is a composite metal panel made by bonding copper and steel together. The process uses heat and pressure to join the two metals into one solid piece. This gives you the strength of steel with the conductivity and corrosion resistance of copper.

How is roll bonded stainless steel cladded sheet made?

Manufacturers start with layers of stainless steel and carbon steel. They clean the surfaces well. Then they stack them and pass the stack through heavy rollers under high heat. This hot bonding fuses the layers tightly without melting them.

Why use carbon steel composite metal panels?

Carbon steel adds strength and lowers cost. Stainless steel or copper on the surface gives better resistance to rust and wear. You get a strong, affordable material that lasts longer in tough environments.

Is hot bonding better than other methods?

Hot bonding creates a stronger bond between the metals. It works at high temperatures but below melting points. This method avoids weak spots and keeps the layers from separating during use or cutting.

Can you weld or machine these cladded sheets?

Yes, you can weld and machine them like regular steel. But you must follow proper procedures. Use the right filler material for the surface layer. Avoid overheating to keep the bond intact. Most standard tools work fine for cutting or shaping.

(Copper Steel Clad Plate Roll Bonded Stainless Steel Cladded Sheet Carbon Steel Composite Metal Panel Hot Bonding Plate)