Overview of copper steel Composite Panel SS304 Composite Aluminum/Copper /Titanium/ Nickel-Alloy KS Clad Steel Sheet

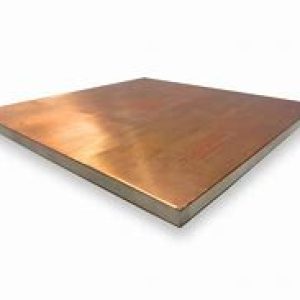

copper steel Composite Panel SS304 Composite Aluminum/Copper /Titanium/ Nickel-Alloy KS Clad Steel Sheet is an innovative building material that seamlessly bonds a copper veneer to a robust steel core. This fusion creates a panel that combines the timeless, elegant aesthetic of copper with the exceptional strength and durability of steel. It is engineered for high-performance architectural cladding and signage, offering a premium, long-lasting solution for modern construction and design projects.

Features of copper steel Composite Panel SS304 Composite Aluminum/Copper /Titanium/ Nickel-Alloy KS Clad Steel Sheet

- Dual-Material Advantage: Marries the classic, evolving patina of copper with the structural rigidity and impact resistance of steel.

- Lightweight & Easy to Install: Significantly lighter than solid copper or steel plates, simplifying handling and reducing structural support costs.

- Exceptional Flatness: The composite construction ensures a consistently smooth, ripple-free surface for a flawless appearance.

- Weather & Corrosion Resistance: Offers outstanding durability against the elements, with the copper surface providing natural protective oxidation over time.

- Flexible Fabrication: Can be easily cut, bent, and shaped to meet complex architectural designs and custom specifications.

Applications of copper steel Composite Panel SS304 Composite Aluminum/Copper /Titanium/ Nickel-Alloy KS Clad Steel Sheet

Ideal for exterior and interior applications where beauty and resilience are paramount. Common uses include:

- Architectural facades, cladding, and curtain walls

- Soffits, canopies, and column covers

- High-end interior feature walls and accents

- Durable and distinctive signage and branding elements

- Renovation projects for a modern, premium upgrade

(copper steel Composite Panel SS304 Composite Aluminum/Copper /Titanium/ Nickel-Alloy KS Clad Steel Sheet)

Parameters of copper steel Composite Panel SS304 Composite Aluminum/Copper /Titanium/ Nickel-Alloy KS Clad Steel Sheet

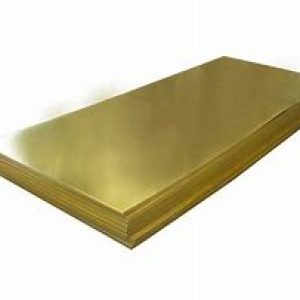

Copper steel composite panel SS304 is a layered material made by bonding stainless steel 304 with copper. This item integrates the toughness of steel with the conductivity and corrosion resistance of copper. It is also available in various other combinations like light weight aluminum, titanium, or nickel-alloy adhered to KS dressed steel sheet. The bonding process makes use of sophisticated approaches such as explosion welding or warm rolling. These techniques produce a strong metallurgical bond between the layers. The outcome is a single sheet that keeps the most effective qualities of each steel.

The stainless steel side offers high mechanical toughness and good resistance to rust. The copper side provides outstanding thermal and electric conductivity. This makes the panel useful in numerous markets. You can find it in heat exchangers, chemical processing equipment, and electrical elements. The aluminum version is lighter and functions well where weight matters. Titanium variations deal with severe environments like salt water or high temperatures. Nickel-alloy versions resist rough chemicals and prevail in petrochemical plants.

Thickness can differ based upon consumer needs. Regular overall density arrays from 2 mm to 50 mm. The proportion of base steel to cladding metal can be readjusted. Usual cladding percents are 10% to 20% of the total thickness. Surface area finish options consist of mill coating, marinaded, or combed. All sheets meet international requirements for top quality and performance. They pass rigorous tests for bond strength and harmony.

These composite panels decrease material prices. You obtain the surface area buildings of costly steels with the architectural assistance of more affordable steel. Construction is very easy using requirement tools for cutting, bending, and welding. The item conserves money without sacrificing efficiency. It is a smart selection for engineers searching for dependable, cost-effective options in demanding applications.

(copper steel Composite Panel SS304 Composite Aluminum/Copper /Titanium/ Nickel-Alloy KS Clad Steel Sheet)

Applications of copper steel Composite Panel SS304 Composite Aluminum/Copper /Titanium/ Nickel-Alloy KS Clad Steel Sheet

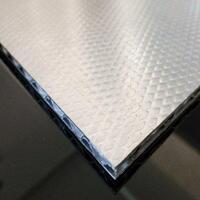

Copper steel composite panels combine the toughness of steel with the special homes of copper. These panels use SS304 stainless-steel as a base layer. They are bound with copper, light weight aluminum, titanium, or nickel alloys through a procedure called cladding. This creates a solid, durable product that works well in challenging environments.

The panels stand up to deterioration much better than regular steel. Copper adds electric and thermal conductivity. Aluminum makes the panel lighter without shedding much stamina. Titanium uses high resistance to heat and chemicals. Nickel alloys take care of extreme temperatures and stay secure in hostile chemical settings.

These composite sheets are used in lots of industries. In chemical handling plants, they line reactors and storage tanks. Their resistance to acids and alkalis makes them perfect for such jobs. Power plants use them in heat exchangers and condensers due to the fact that they move heat well and last long. The electronics sector uses copper-clad variations for grounding and securing because of their conductivity.

Shipbuilding additionally takes advantage of these products. Salt water is rough on metals, but the attired layers shield the steel beneath. Offshore systems use them for comparable factors. In style, developers choose them for roofing systems and exteriors where looks and resilience issue with each other.

Manufacturers create these panels in different densities and sizes. The bonding process makes certain no gaps or weak spots in between layers. Quality assurance checks guarantee consistent performance. Consumers can get customized mixes based upon their demands. For instance, a job may require copper on one side and titanium on the other.

Handling and cutting these panels adhere to basic metalworking techniques. They can be bonded, bent, or drilled like normal steel in most cases. This makes installation much easier and much faster. Upkeep expenses remain low because the surface area stands up to wear and corrosion.

Company Profile

Metal Plate 4 U is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Copper Steel Composite Panel

1. How does the patina (weathering) of the copper surface affect the panel?

The natural patina formation is a desirable feature, creating a beautiful, protective layer that enhances corrosion resistance and adds character over time. The rate can vary based on local environmental conditions.

2. Is the panel suitable for coastal or high-humidity environments?

Yes. The inherent properties of copper and the protective coating on the steel core provide excellent resistance to salt spray and moisture, making it a suitable choice for such applications.

3. Can the panels be curved or formed into specific shapes?

Absolutely. The composite construction allows for good formability. Panels can be cold-curved or fabricated into various shapes to meet specific design requirements.

4. What are the installation and maintenance requirements?

Installation follows standard practices for composite panels using appropriate mechanical fixing systems. Maintenance is minimal, typically requiring only occasional cleaning with water and a mild detergent.

5. How does the cost compare to solid copper panels?

Copper Steel Composite Panels offer a considerable cost advantage over solid copper, providing the same prestigious look with reduced material weight, easier installation, and often lower overall project costs.

5 FAQs of copper steel Composite Panel SS304 Composite Aluminum/Copper /Titanium/ Nickel-Alloy KS Clad Steel Sheet

What is copper steel composite panel?

It is a layered material made by bonding copper with steel. The copper gives good corrosion resistance and looks nice. The steel adds strength and keeps costs lower than solid copper.

Why choose SS304 composite over solid stainless steel?

SS304 composite uses less stainless steel but still keeps strong performance. It saves money and weighs less. It works well in places where full stainless steel is not needed.

Can aluminum, copper, titanium, or nickel alloys be bonded to steel?

Yes. These metals can be cladded onto steel using special methods. Each metal brings its own benefit. Aluminum is light. Copper conducts heat well. Titanium resists saltwater. Nickel alloys handle high heat and harsh chemicals.

How is KS clad steel sheet made?

KS clad steel is made through explosion bonding or hot rolling. These methods press the two metals together under high pressure or heat. The bond becomes strong and lasts long without peeling.

Where are these composite sheets used?

They are used in chemical plants, shipbuilding, heat exchangers, and architecture. Any place that needs both strength and special surface properties uses them. They help cut material costs while keeping performance high.

(copper steel Composite Panel SS304 Composite Aluminum/Copper /Titanium/ Nickel-Alloy KS Clad Steel Sheet)