Overview of copper steellic Copper Clad Plate Fast Shipping H90+F11/F18+H90 Cold Rolled C1100 C2680 C2200 Copper Steel Aluminum Composite Plate

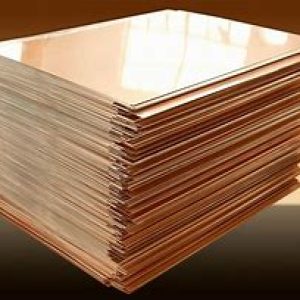

copper steellic Copper Clad Plate Fast Shipping H90+F11/F18+H90 Cold Rolled C1100 C2680 C2200 Copper Steel Aluminum Composite Plate is an innovative building material that seamlessly bonds a copper veneer to a robust steel core. This fusion creates a panel that combines the timeless, elegant aesthetic of copper with the exceptional strength and durability of steel. It is engineered for high-performance architectural cladding and signage, offering a premium, long-lasting solution for modern construction and design projects.

Features of copper steellic Copper Clad Plate Fast Shipping H90+F11/F18+H90 Cold Rolled C1100 C2680 C2200 Copper Steel Aluminum Composite Plate

- Dual-Material Advantage: Marries the classic, evolving patina of copper with the structural rigidity and impact resistance of steel.

- Lightweight & Easy to Install: Significantly lighter than solid copper or steel plates, simplifying handling and reducing structural support costs.

- Exceptional Flatness: The composite construction ensures a consistently smooth, ripple-free surface for a flawless appearance.

- Weather & Corrosion Resistance: Offers outstanding durability against the elements, with the copper surface providing natural protective oxidation over time.

- Flexible Fabrication: Can be easily cut, bent, and shaped to meet complex architectural designs and custom specifications.

Applications of copper steellic Copper Clad Plate Fast Shipping H90+F11/F18+H90 Cold Rolled C1100 C2680 C2200 Copper Steel Aluminum Composite Plate

Ideal for exterior and interior applications where beauty and resilience are paramount. Common uses include:

- Architectural facades, cladding, and curtain walls

- Soffits, canopies, and column covers

- High-end interior feature walls and accents

- Durable and distinctive signage and branding elements

- Renovation projects for a modern, premium upgrade

(copper steellic Copper Clad Plate Fast Shipping H90+F11/F18+H90 Cold Rolled C1100 C2680 C2200 Copper Steel Aluminum Composite Plate)

Parameters of copper steellic Copper Clad Plate Fast Shipping H90+F11/F18+H90 Cold Rolled C1100 C2680 C2200 Copper Steel Aluminum Composite Plate

Copper clad plate combines copper with steel or light weight aluminum to supply strong performance and excellent conductivity. This product makes use of chilly rolled materials like C1100, C2680, and C2200 copper qualities. It likewise includes steel layers noted as F11 or F18, plus H90 copper on both sides. The structure is H90 + F11/F18 + H90, which indicates copper covers both outer surfaces with steel in the middle. This design gives you the advantages of copper– such as high electric and thermal conductivity– in addition to the strength and longevity of steel or light weight aluminum.

Home plate is made via a cool rolling process. This approach guarantees limited bonding between the layers without spaces or vulnerable points. It additionally keeps the surface area smooth and attire. You can utilize this composite material in many markets. Usual applications consist of electric elements, warm exchangers, busbars, and protecting components. The mix of steels makes it perfect where you need both conductivity and mechanical assistance.

We maintain this copper steel dressed plate in stock for fast shipping. A lot of orders head out within one or two organization days. The standard density arrays from 0.5 mm to 6 mm, however personalized sizes are feasible. Widths normally increase to 1200 mm. All plates meet industry requirements for quality and efficiency. Each batch undergoes strict testing to examine bond toughness, surface area finish, and make-up.

This item works well when you intend to reduce costs without losing efficiency. Pure copper is pricey, but using a steel core with thin copper layers provides similar results at a reduced rate. It additionally weighs less than solid copper, which assists in transportation and installment. The material stands up to corrosion and holds up under typical operating problems. You can machine it, flex it, or bonded it using common techniques. Simply follow fundamental safety steps when dealing with or processing the plate.

(copper steellic Copper Clad Plate Fast Shipping H90+F11/F18+H90 Cold Rolled C1100 C2680 C2200 Copper Steel Aluminum Composite Plate)

Applications of copper steellic Copper Clad Plate Fast Shipping H90+F11/F18+H90 Cold Rolled C1100 C2680 C2200 Copper Steel Aluminum Composite Plate

Copper steel outfitted plates incorporate the toughness of steel with the conductivity and corrosion resistance of copper. These composite plates are made by bonding layers of copper and steel with each other with a cool rolling process. Common grades include H90+F11, F18+H90, C1100, C2680, and C2200. Each grade uses a specific balance of mechanical buildings and electric efficiency.

These plates are extensively utilized in electrical and digital sectors. They serve as trusted products for busbars, ports, and terminals where both high conductivity and structural support are required. The copper layer ensures reliable existing flow while the steel core adds sturdiness and minimizes general cost compared to pure copper.

In the auto market, copper steel outfitted plates appear in battery systems and power distribution systems. Their capability to take care of thermal cycling and withstand wear makes them ideal for requiring environments. Shipbuilding additionally takes advantage of these compounds. They are used in basing systems and marine electric setups due to the fact that they stand up to deep sea deterioration much better than many alternatives.

Warmth exchangers and industrial machinery use these plates also. The combination of excellent thermal conductivity from copper and high stamina from steel supports reliable warmth transfer and lengthy service life. Producers pick them when they need a product that executes well under stress and anxiety and temperature level adjustments.

Aluminum can also belong to the composite framework in some variations. Copper steel light weight aluminum clothed plates supply a lot more flexibility in style. They are lighter and useful in applications where weight issues, such as aerospace components or mobile electronics.

Rapid shipping is offered for typical sizes and usual qualities. This helps consumers fulfill tight manufacturing schedules right away. Inventory includes chilly rolled alternatives that provide smooth surface areas and regular density, which are essential for precision manufacturing.

Company Profile

Metal Plate 4 U is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Copper Steel Composite Panel

1. How does the patina (weathering) of the copper surface affect the panel?

The natural patina formation is a desirable feature, creating a beautiful, protective layer that enhances corrosion resistance and adds character over time. The rate can vary based on local environmental conditions.

2. Is the panel suitable for coastal or high-humidity environments?

Yes. The inherent properties of copper and the protective coating on the steel core provide excellent resistance to salt spray and moisture, making it a suitable choice for such applications.

3. Can the panels be curved or formed into specific shapes?

Absolutely. The composite construction allows for good formability. Panels can be cold-curved or fabricated into various shapes to meet specific design requirements.

4. What are the installation and maintenance requirements?

Installation follows standard practices for composite panels using appropriate mechanical fixing systems. Maintenance is minimal, typically requiring only occasional cleaning with water and a mild detergent.

5. How does the cost compare to solid copper panels?

Copper Steel Composite Panels offer a considerable cost advantage over solid copper, providing the same prestigious look with reduced material weight, easier installation, and often lower overall project costs.

5 FAQs of copper steellic Copper Clad Plate Fast Shipping H90+F11/F18+H90 Cold Rolled C1100 C2680 C2200 Copper Steel Aluminum Composite Plate

What is copper steel clad plate?

Copper steel clad plate is a composite material made by bonding copper or copper alloy to steel. It combines the high conductivity and corrosion resistance of copper with the strength and low cost of steel. Common grades include H90+F11/F18+H90, C1100, C2680, and C2200.

Why choose cold rolled copper steel clad plate?

Cold rolling improves surface finish and dimensional accuracy. It also increases strength without adding weight. This makes the plate ideal for parts that need precision and durability.

What are the main uses of this composite plate?

It is used in electrical connectors, heat exchangers, busbars, and automotive parts. The copper layer handles electrical and thermal needs while the steel core provides structural support.

How fast is the shipping?

We offer fast shipping on all standard sizes and grades. Most orders ship within 1–3 business days after confirmation. Delivery time depends on your location and order size.

Is this material easy to work with?

Yes. You can cut, bend, and machine it using standard tools. The bond between copper and steel stays strong during forming. Just follow recommended practices for each layer to avoid damage.

(copper steellic Copper Clad Plate Fast Shipping H90+F11/F18+H90 Cold Rolled C1100 C2680 C2200 Copper Steel Aluminum Composite Plate)