Overview of Factory Whole Copper Rust Copper Facade Cladding Oxidized Steel Board for Interior and Exterior Cladding With Low

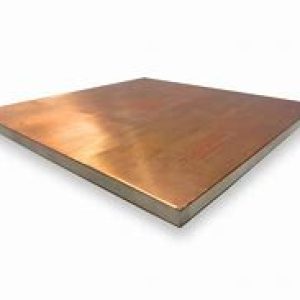

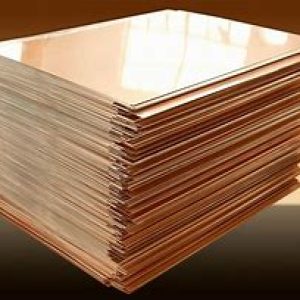

Factory Whole Copper Rust Copper Facade Cladding Oxidized Steel Board for Interior and Exterior Cladding With Low is an innovative building material that seamlessly bonds a copper veneer to a robust steel core. This fusion creates a panel that combines the timeless, elegant aesthetic of copper with the exceptional strength and durability of steel. It is engineered for high-performance architectural cladding and signage, offering a premium, long-lasting solution for modern construction and design projects.

Features of Factory Whole Copper Rust Copper Facade Cladding Oxidized Steel Board for Interior and Exterior Cladding With Low

- Dual-Material Advantage: Marries the classic, evolving patina of copper with the structural rigidity and impact resistance of steel.

- Lightweight & Easy to Install: Significantly lighter than solid copper or steel plates, simplifying handling and reducing structural support costs.

- Exceptional Flatness: The composite construction ensures a consistently smooth, ripple-free surface for a flawless appearance.

- Weather & Corrosion Resistance: Offers outstanding durability against the elements, with the copper surface providing natural protective oxidation over time.

- Flexible Fabrication: Can be easily cut, bent, and shaped to meet complex architectural designs and custom specifications.

Applications of Factory Whole Copper Rust Copper Facade Cladding Oxidized Steel Board for Interior and Exterior Cladding With Low

Ideal for exterior and interior applications where beauty and resilience are paramount. Common uses include:

- Architectural facades, cladding, and curtain walls

- Soffits, canopies, and column covers

- High-end interior feature walls and accents

- Durable and distinctive signage and branding elements

- Renovation projects for a modern, premium upgrade

(Factory Whole Copper Rust Copper Facade Cladding Oxidized Steel Board for Interior and Exterior Cladding With Low )

Parameters of Factory Whole Copper Rust Copper Facade Cladding Oxidized Steel Board for Interior and Exterior Cladding With Low

Factory entire copper and rust copper facade cladding deals a strong try to find both interior and exterior walls. This oxidized steel board comes with an all-natural aged finish that includes character to any room. The material is made from strong copper or steel treated to produce a stable rust layer. This layer secures the steel beneath and provides it a special color that changes gradually.

The panels are strong and constructed to last. They withstand weather condition, moisture, and daily wear. That makes them suitable for exterior use like structure facades, verandas, or yard features. Indoors, they work well as accent walls, reception workdesks, or attractive partitions.

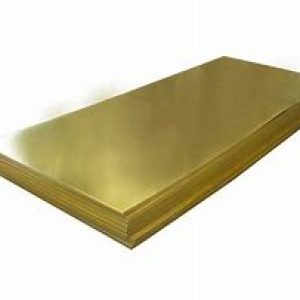

Standard thickness alternatives range from 0.5 mm to 3.0 mm. Thicker boards supply even more strength and are much better for large surfaces. Thinner sheets fit thorough designs or rounded installments. Panel dimensions can be tailored but frequently can be found in widths of 1000 mm to 1250 mm and sizes up to 6000 mm.

Setup is basic with typical attachment techniques. Surprise clips or noticeable screws both work depending upon the layout objective. The surface needs no paint or sealing. It preserves its appearance with marginal upkeep. Just occasional cleaning keeps it fresh.

Color differs from deep brownish to reddish-orange based upon the oxidation process. Each set shows minor differences, which contributes to the hand-made feel. This variant is typical and anticipated.

The product fulfills basic fire and security rankings for building materials. It matches business and residential projects alike. Its raw, commercial design fits modern-day, rustic, and minimalist styles.

These cladding boards ship ready to set up. They show up level and safeguarded to avoid scratches. Preparation depends on order size yet stock things relocate rapidly.

(Factory Whole Copper Rust Copper Facade Cladding Oxidized Steel Board for Interior and Exterior Cladding With Low )

Applications of Factory Whole Copper Rust Copper Facade Cladding Oxidized Steel Board for Interior and Exterior Cladding With Low

Manufacturing facility whole copper and corrosion copper frontage cladding, in addition to oxidized steel boards, supply a solid and trendy choice for both interior and exterior surface areas. These products bring an all-natural appearance that changes in time, adding character to any kind of area. Copper begins with a bright metal shine yet gradually becomes an abundant brown and then a green aging when subjected to air and moisture. Rust copper shows warm reddish tones that grow with age. Oxidized steel establishes a secure corrosion layer that safeguards the metal below while offering it a natural, industrial feeling.

People use these cladding types on building outsides to create captivating wall surfaces that stick out in city or rural settings. They work well on commercial buildings, workplaces, and even homes. Inside, they add texture and warmth to lobbies, restaurants, stores, and function wall surfaces. The raw, unfinished look fits modern, rustic, and commercial design styles.

These materials are long lasting and require little maintenance as soon as installed. The natural oxidation process actually aids safeguard the metal from further rust. That makes them appropriate for severe weather without shedding their visual allure. They also match conveniently with wood, glass, concrete, and various other common building products.

Installment is simple utilizing common metal cladding methods. The panels come in consistent dimensions from the factory, which helps quicken the structure process. Their weight is manageable for many support frameworks. In time, the surface area develops, narrating via its altering color and texture. This living high quality makes each job unique. Designers and designers choose these products when they want something real, truthful, and loaded with existence. They bring a sense of time and area to any type of environment, inside your home or out.

Company Profile

Metal Plate 4 U is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Copper Steel Composite Panel

1. How does the patina (weathering) of the copper surface affect the panel?

The natural patina formation is a desirable feature, creating a beautiful, protective layer that enhances corrosion resistance and adds character over time. The rate can vary based on local environmental conditions.

2. Is the panel suitable for coastal or high-humidity environments?

Yes. The inherent properties of copper and the protective coating on the steel core provide excellent resistance to salt spray and moisture, making it a suitable choice for such applications.

3. Can the panels be curved or formed into specific shapes?

Absolutely. The composite construction allows for good formability. Panels can be cold-curved or fabricated into various shapes to meet specific design requirements.

4. What are the installation and maintenance requirements?

Installation follows standard practices for composite panels using appropriate mechanical fixing systems. Maintenance is minimal, typically requiring only occasional cleaning with water and a mild detergent.

5. How does the cost compare to solid copper panels?

Copper Steel Composite Panels offer a considerable cost advantage over solid copper, providing the same prestigious look with reduced material weight, easier installation, and often lower overall project costs.

5 FAQs of Factory Whole Copper Rust Copper Facade Cladding Oxidized Steel Board for Interior and Exterior Cladding With Low

What is factory whole copper rust copper facade cladding?

It is a type of metal panel made from solid copper or oxidized steel. The surface shows natural rust or patina effects. It is used on building walls both inside and outside.

Is this cladding suitable for outdoor use?

Yes. The material resists weather well. Over time, the surface forms a stable oxide layer. This layer protects the metal underneath from further corrosion. It works in rain, sun, and wind without peeling or cracking.

How long does the finish last?

The finish lasts many years. Copper develops a greenish patina slowly. Oxidized steel keeps its rust look but stays stable. Both need little maintenance once installed.

Can it be used indoors?

Yes. It adds a unique look to interiors like lobbies, restaurants, or offices. The rustic texture brings warmth and character. It pairs well with wood, concrete, or glass.

Is installation difficult?

No. The panels come in standard sizes. They fix to walls using common mounting systems. Skilled workers can install them quickly. No special tools are needed beyond what is used for regular metal cladding.

This cladding offers durability and style. It suits modern and industrial designs. The natural aging process gives each project a one-of-a-kind appearance. It performs well in different climates. Homeowners and builders choose it for its low upkeep and strong visual impact.

(Factory Whole Copper Rust Copper Facade Cladding Oxidized Steel Board for Interior and Exterior Cladding With Low )