Overview of High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints

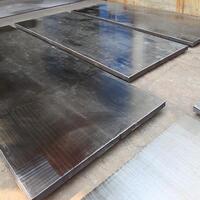

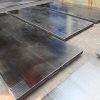

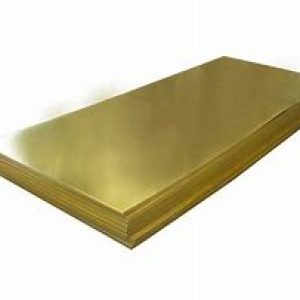

High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints is an innovative building material that seamlessly bonds a copper veneer to a robust steel core. This fusion creates a panel that combines the timeless, elegant aesthetic of copper with the exceptional strength and durability of steel. It is engineered for high-performance architectural cladding and signage, offering a premium, long-lasting solution for modern construction and design projects.

Features of High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints

- Dual-Material Advantage: Marries the classic, evolving patina of copper with the structural rigidity and impact resistance of steel.

- Lightweight & Easy to Install: Significantly lighter than solid copper or steel plates, simplifying handling and reducing structural support costs.

- Exceptional Flatness: The composite construction ensures a consistently smooth, ripple-free surface for a flawless appearance.

- Weather & Corrosion Resistance: Offers outstanding durability against the elements, with the copper surface providing natural protective oxidation over time.

- Flexible Fabrication: Can be easily cut, bent, and shaped to meet complex architectural designs and custom specifications.

Applications of High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints

Ideal for exterior and interior applications where beauty and resilience are paramount. Common uses include:

- Architectural facades, cladding, and curtain walls

- Soffits, canopies, and column covers

- High-end interior feature walls and accents

- Durable and distinctive signage and branding elements

- Renovation projects for a modern, premium upgrade

(High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints)

Parameters of High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints

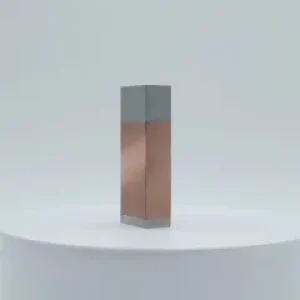

High-strength copper steel composite plate made in China is developed for surge bonding and shift joints. This product incorporates the toughness of steel with the conductivity and deterioration resistance of copper. The bonding procedure makes use of controlled explosions to fuse the two steels with each other. This creates a strong, dependable joint that holds up under high tension and severe conditions.

The steel layer supplies architectural assistance and longevity. The copper layer supplies exceptional electric and thermal conductivity. With each other, they develop a composite that functions well popular industrial applications. Typical usages consist of power transmission tools, shipbuilding, chemical handling plants, and warm exchangers.

Common thickness arrays from 4 mm to 50 mm. The copper side normally measures in between 1 mm and 10 mm thick. The steel base can be carbon steel, low-alloy steel, or stainless-steel, relying on the need. The copper utilized meets conventional purity degrees, typically above 99.9%.

Bond toughness is a crucial criterion. It typically surpasses 200 MPa, making sure the layers stay securely attached throughout procedure. Shear toughness and tensile toughness are also examined to confirm efficiency. The user interface in between copper and steel reveals no voids or weak points when inspected with ultrasound or other non-destructive methods.

Surface area high quality matters as well. Both sides are cleaned up and smoothed to fulfill sector criteria. Sides are cut uniformly. Plates can be cut, bent, or machined without harming the bond. Customized sizes and shapes are readily available based on project requirements.

Suppliers in China comply with rigorous quality assurance steps. Each set goes through chemical evaluation, mechanical testing, and aesthetic checks. Accreditations like ISO 9001 and material examination reports are offered with every order. This guarantees users get a regular, reliable item whenever.

(High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints)

Applications of High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints

High-strength copper steel composite plate made in China is widely made use of where strong, trusted bonding between copper and steel is required. This product integrates the high thermal and electrical conductivity of copper with the stamina and durability of steel. It is produced making use of explosion bonding, an approach that signs up with the two metals strongly without thawing them.

One significant usage is in power generation tools. Warm exchangers, condensers, and central heating boiler components commonly require this composite plate due to the fact that it manages warmth well and withstands deterioration. In shipbuilding, it appears in aquatic condensers and piping systems that must operate in salty, rough settings. The copper side battles corrosion from salt water while the steel side gives structural assistance.

The petrochemical market also counts on this product. Activators, distillation columns, and tank use copper steel change joints to attach various metal components securely. These joints prevent galvanic corrosion and minimize stress and anxiety at connection points. That helps prolong equipment life and decreases upkeep expenses.

Electric grounding systems benefit too. Copper performs electrical energy better than steel, yet steel is stronger. By utilizing the composite plate, designers get both advantages unharmed. It makes certain steady grounding while holding up under mechanical tons.

China’s manufacturing of this composite plate meets worldwide standards. Producers regulate top quality securely throughout surge bonding to prevent flaws like fractures or weak bonds. The outcome is a reliable product that performs well popular applications.

Due to the fact that it fixes the trouble of joining different steels efficiently, this composite plate has ended up being essential in numerous hefty industries. Its performance in high-temperature, high-pressure, or corrosive settings makes it a wise choice for designers looking for long-lasting reliability.

Company Profile

Metal Plate 4 U is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Copper Steel Composite Panel

1. How does the patina (weathering) of the copper surface affect the panel?

The natural patina formation is a desirable feature, creating a beautiful, protective layer that enhances corrosion resistance and adds character over time. The rate can vary based on local environmental conditions.

2. Is the panel suitable for coastal or high-humidity environments?

Yes. The inherent properties of copper and the protective coating on the steel core provide excellent resistance to salt spray and moisture, making it a suitable choice for such applications.

3. Can the panels be curved or formed into specific shapes?

Absolutely. The composite construction allows for good formability. Panels can be cold-curved or fabricated into various shapes to meet specific design requirements.

4. What are the installation and maintenance requirements?

Installation follows standard practices for composite panels using appropriate mechanical fixing systems. Maintenance is minimal, typically requiring only occasional cleaning with water and a mild detergent.

5. How does the cost compare to solid copper panels?

Copper Steel Composite Panels offer a considerable cost advantage over solid copper, providing the same prestigious look with reduced material weight, easier installation, and often lower overall project costs.

5 FAQs of High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints

What is a high-strength copper steel composite plate?

It is a metal plate made by bonding copper and steel together using explosion bonding. This method creates a strong joint between the two metals. The result keeps the good qualities of both materials—copper’s conductivity and steel’s strength.

Why use explosion bonding for this plate?

Explosion bonding uses controlled blasts to join copper and steel. This process makes a solid, clean bond without melting the metals. It avoids weak spots or impurities that other methods might cause.

Where are these plates used?

They are often used in industries like shipbuilding, power generation, and chemical processing. These fields need parts that handle heat well and resist corrosion. The copper side deals with electrical or thermal tasks, while the steel side gives structural support.

How strong is the bond between copper and steel?

The bond is very strong. Tests show it meets or exceeds international standards for shear strength and tensile strength. The joint stays stable even under high stress or temperature changes.

Are Chinese-made copper steel composite plates reliable?

Yes. Many Chinese manufacturers follow strict quality controls and international norms. They use advanced explosion bonding tech and test every batch. Buyers get consistent performance and good value.

(High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints)