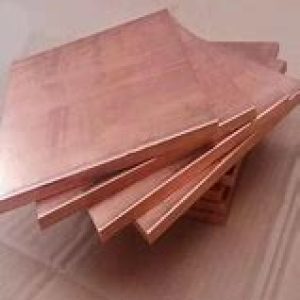

Overview of Metal Alloy copper steellic Sheet Cladding Bonding Steel Panel Plate Copper Aluminum Composite Plate

Metal Alloy copper steellic Sheet Cladding Bonding Steel Panel Plate Copper Aluminum Composite Plate is an innovative building material that seamlessly bonds a copper veneer to a robust steel core. This fusion creates a panel that combines the timeless, elegant aesthetic of copper with the exceptional strength and durability of steel. It is engineered for high-performance architectural cladding and signage, offering a premium, long-lasting solution for modern construction and design projects.

Features of Metal Alloy copper steellic Sheet Cladding Bonding Steel Panel Plate Copper Aluminum Composite Plate

- Dual-Material Advantage: Marries the classic, evolving patina of copper with the structural rigidity and impact resistance of steel.

- Lightweight & Easy to Install: Significantly lighter than solid copper or steel plates, simplifying handling and reducing structural support costs.

- Exceptional Flatness: The composite construction ensures a consistently smooth, ripple-free surface for a flawless appearance.

- Weather & Corrosion Resistance: Offers outstanding durability against the elements, with the copper surface providing natural protective oxidation over time.

- Flexible Fabrication: Can be easily cut, bent, and shaped to meet complex architectural designs and custom specifications.

Applications of Metal Alloy copper steellic Sheet Cladding Bonding Steel Panel Plate Copper Aluminum Composite Plate

Ideal for exterior and interior applications where beauty and resilience are paramount. Common uses include:

- Architectural facades, cladding, and curtain walls

- Soffits, canopies, and column covers

- High-end interior feature walls and accents

- Durable and distinctive signage and branding elements

- Renovation projects for a modern, premium upgrade

(Metal Alloy copper steellic Sheet Cladding Bonding Steel Panel Plate Copper Aluminum Composite Plate)

Parameters of Metal Alloy copper steellic Sheet Cladding Bonding Steel Panel Plate Copper Aluminum Composite Plate

Metal alloy copper steellic sheet cladding bonding steel panel plate is a layered material made by signing up with copper and steel or light weight aluminum with strong bonding strategies. This composite plate incorporates the most effective attributes of each steel. Copper provides great electrical and thermal conductivity together with corrosion resistance. Steel includes strength and durability. Aluminum brings light weight and extra corrosion defense. The result is a functional item appropriate for several industrial uses.

The bonding procedure ensures a solid connection between the layers. It stops splitting up under tension, warmth, or pressure. This makes the plate reliable popular settings. Common approaches include roll bonding, explosion bonding, or hot pressing. Each technique produces an uniform bond without voids or weak points.

These composite plates can be found in different thicknesses and sizes. The copper layer can be thin or thick depending on the application. The steel or light weight aluminum base offers structural assistance. Customers can select the right mix based upon their demands for stamina, weight, or conductivity.

Industries utilize this material in heat exchangers, electric components, architectural panels, and aquatic devices. Its capability to stand up to rust and handle high temperatures makes it perfect for rough problems. The surface area can likewise be brightened or coated for better looks or added protection.

Quality control checks guarantee consistent efficiency. Examinations gauge bond toughness, monotony, and resistance to environmental factors. Suppliers follow rigorous standards to supply risk-free and dependable items. The plates are easy to reduce, bend, and mount using typical devices. This saves time and cost throughout construction.

Since it combines various metals into one system, this composite plate solves troubles that single-metal sheets can not. It cuts down on product costs while improving feature. Users get a clever service that balances efficiency, life expectancy, and worth.

(Metal Alloy copper steellic Sheet Cladding Bonding Steel Panel Plate Copper Aluminum Composite Plate)

Applications of Metal Alloy copper steellic Sheet Cladding Bonding Steel Panel Plate Copper Aluminum Composite Plate

Steel alloy copper steellic sheet cladding uses solid performance in numerous building and industrial usages. This product bonds steel with copper or light weight aluminum to produce a long lasting composite plate. The steel core gives architectural strength. The outer copper or aluminum layer adds corrosion resistance and an appealing surface. With each other, they form a panel that is both tough and long-lasting.

Building contractors utilize these adhered panels for roof covering, wall surface cladding, and exteriors. The mix of steels handles weather condition changes well. It withstands corrosion, salt, and contamination. That makes it suitable for seaside locations or cities with heavy traffic. Manufacturing facilities and plants likewise choose this material for devices covers and safety linings. It stands up to heat, chemicals, and physical wear.

The bonding process integrates the layers firmly. This protects against separation with time. The outcome is an uniform surface area that remains stable under stress. Installers find the panels simple to cut, form, and solution in place. They deal with basic devices and fasteners. Upkeep stays low due to the fact that the surface area does not need frequent paint or sealing.

Engineers like the look of copper and aluminum surfaces. They provide a contemporary or traditional appearance relying on the layout. In time, copper develops a natural patina that several like. Light weight aluminum maintains a tidy, intense look with little effort. Both alternatives offer designers flexibility without sacrificing function.

These composite plates additionally support sustainability goals. They last for decades, which lowers substitute needs. Numerous components can be recycled at the end of their life. Energy usage throughout production stays lower than with some options. That helps reduce the overall ecological impact.

Industries from construction to transportation depend on this steel combo. It fixes issues where toughness, looks, and sturdiness has to work together. The bound structure provides consistent top quality in real-world conditions. Individuals get a reputable item that does every day.

Company Profile

Metal Plate 4 U is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Copper Steel Composite Panel

1. How does the patina (weathering) of the copper surface affect the panel?

The natural patina formation is a desirable feature, creating a beautiful, protective layer that enhances corrosion resistance and adds character over time. The rate can vary based on local environmental conditions.

2. Is the panel suitable for coastal or high-humidity environments?

Yes. The inherent properties of copper and the protective coating on the steel core provide excellent resistance to salt spray and moisture, making it a suitable choice for such applications.

3. Can the panels be curved or formed into specific shapes?

Absolutely. The composite construction allows for good formability. Panels can be cold-curved or fabricated into various shapes to meet specific design requirements.

4. What are the installation and maintenance requirements?

Installation follows standard practices for composite panels using appropriate mechanical fixing systems. Maintenance is minimal, typically requiring only occasional cleaning with water and a mild detergent.

5. How does the cost compare to solid copper panels?

Copper Steel Composite Panels offer a considerable cost advantage over solid copper, providing the same prestigious look with reduced material weight, easier installation, and often lower overall project costs.

5 FAQs of Metal Alloy copper steellic Sheet Cladding Bonding Steel Panel Plate Copper Aluminum Composite Plate

What is metal alloy copper steellic sheet cladding?

It is a bonded panel made by joining copper and steel layers. The copper gives a decorative look and resists corrosion. The steel adds strength and keeps costs lower than solid copper.

Why choose copper-steel composite over solid copper?

Solid copper is expensive and soft. The composite uses less copper but keeps its good looks and weather resistance. The steel core makes the panel stronger and easier to handle during installation.

How is the bonding between copper and steel achieved?

The layers are bonded using heat and pressure in a controlled process. This creates a strong metallurgical bond. The result is a single plate that will not separate under normal use or temperature changes.

Can this material be used outdoors?

Yes. The copper surface forms a protective patina over time. This layer stops further corrosion. The steel underneath stays protected as long as the copper layer remains intact. It works well for roofs, walls, and facades.

Is it easy to cut and shape on site?

It can be cut and bent using standard metalworking tools. However, care must be taken to avoid cracking the copper layer. Simple bends and cuts are fine. Complex shapes may need factory pre-forming to keep the bond strong and the finish clean.

(Metal Alloy copper steellic Sheet Cladding Bonding Steel Panel Plate Copper Aluminum Composite Plate)