Overview of Metal Composite Sandwich Panel: Combines Both Metal Compositeand Sandwich Properties, Highly Versatile

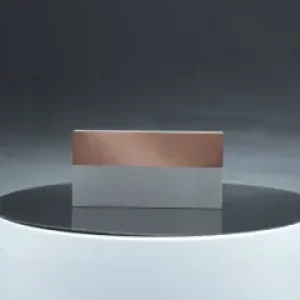

Metal Composite Sandwich Panel: Combines Both Metal Compositeand Sandwich Properties, Highly Versatile is an innovative building material consisting of two outer metal skins bonded to a solid thermoplastic core. This engineered structure creates a lightweight, flat, and rigid panel ideal for modern architectural cladding and signage, offering superior durability and a sleek aesthetic finish.

Features of Metal Composite Sandwich Panel: Combines Both Metal Compositeand Sandwich Properties, Highly Versatile

- Lightweight & High Strength: Exceptional strength-to-weight ratio for easier handling and reduced structural load.

- Excellent Flatness: Maintains a smooth, unwavering surface for a flawless appearance.

- Superior Weather Resistance: Resists corrosion, fading, and weathering for long-lasting performance.

- Versatile Formability: Can be curved, bent, and shaped to meet diverse design requirements.

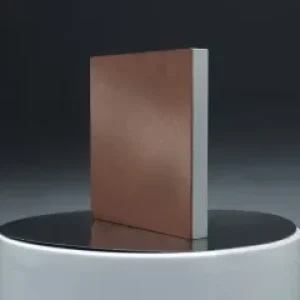

- Wide Range of Finishes: Available in various colors, metallic coatings, and textures (e.g., PVDF, PE, Anodized).

Applications of Metal Composite Sandwich Panel: Combines Both Metal Compositeand Sandwich Properties, Highly Versatile

- Architectural Cladding: Exterior façades, curtain walls, and rainscreen systems for commercial and residential buildings.

- Interior Design: Feature walls, ceilings, column covers, and retail displays.

- Signage & Branding: Durable and visually striking signage for businesses and infrastructure.

- Industrial Design: Used in fabrication for machine panels, clean rooms, and decorative surfaces.

(Metal Composite Sandwich Panel: Combines Both Metal Compositeand Sandwich Properties, Highly Versatile)

Specification of Metal Composite Sandwich Panel: Combines Both Metal Compositeand Sandwich Properties, Highly Versatile

Steel composite sandwich panels combine the best of steel compounds and sandwich structures. They have a strong outer layer made of steel. The core inside is lightweight however company. This mix offers the panel great stamina without adding much weight. People utilize these panels in numerous locations due to the fact that they function well in different situations.

The external steel skin can be light weight aluminum, steel, or other metals. It safeguards the panel from weather, corrosion, and damages. The inner core is typically constructed from foam, mineral woollen, or plastic. This core includes insulation and assists keep the shape consistent. With each other, these layers make a panel that takes care of tension well and lasts a long time.

These panels are easy to install. They are available in basic dimensions however can also be cut to fit unique requirements. Building contractors like them due to the fact that they conserve time on website. The panels additionally look clean and modern-day, so they fit both wall surfaces and roofing systems.

They carry out well in fire, sound, and warmth tests. Some variations satisfy stringent safety and security regulations for buildings. Others provide excellent thermal insulation, which aids cut energy costs. Their style blocks noise as well, making rooms quieter inside.

Since they are light, they put much less tons on the building framework. That suggests support frameworks can be less complex and more affordable. Transport is less complicated as well. Less journeys are needed to move the very same amount of product.

Steel composite sandwich panels work in factories, offices, stockrooms, and even homes. They take care of severe weather and stay solid in time. Maintenance is low considering that the surface withstands dust and wear. You can cleanse them with simply water and light soap.

Their mix of metal strength and core effectiveness makes them a smart choice for several jobs. They give performance, looks, and function in one straightforward product.

(Metal Composite Sandwich Panel: Combines Both Metal Compositeand Sandwich Properties, Highly Versatile)

Applications of Metal Composite Sandwich Panel: Combines Both Metal Compositeand Sandwich Properties, Highly Versatile

Steel composite sandwich panels unite the most effective of metal composites and sandwich frameworks. These panels have a solid outer layer constructed from metal and a lightweight core in the center. This style provides high strength without including much weight. They are made use of in several markets due to the fact that they function well and last lengthy.

In building, these panels are popular for developing facades and roofs. They look tidy and modern-day. They also stand up to weather and do not rust conveniently. That makes them a wise choice for both workplaces and homes. The panels aid keep structures cool down in summer season and warm in winter months due to the fact that the core functions as insulation.

The transportation sector uses these panels also. Trains, buses, and also planes need products that are light yet difficult. Steel composite sandwich panels fit this demand flawlessly. They cut down on fuel usage since they evaluate less than solid metal. At the exact same time, they protect travelers by staying strong during impact.

Cold store and chilled vehicles also depend on these panels. The insulating core keeps temperatures constant. This conserves power and keeps food or medicine secure throughout travel. Manufacturing facilities and storage facilities utilize them for wall surfaces and ceilings to manage interior environment without additional price.

Also in aquatic settings, these panels perform well. They take care of salt, dampness, and continuous motion without damaging down. Watercrafts and offshore platforms benefit from their longevity and reduced upkeep.

Since they are simple to shape and set up, developers and building contractors like dealing with them. They can be reduced to size promptly and dealt with in place with basic tools. This accelerates jobs and cuts labor costs. Their mix of stamina, lightness, and insulation makes them helpful wherever efficiency and performance issue.

Company Profile

Metal Plate 4 U is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Metal Composite Panel Products

1. What is the core material made of?

Typically, the core is made from low-density polyethylene (PE) or a fire-retardant mineral core for enhanced safety ratings.

2. Are these panels suitable for exterior use?

Yes, when manufactured with appropriate coatings like PVDF, they are highly durable and weather-resistant for exterior cladding.

3. How are the panels installed?

They are installed using specialized rivet or clip systems onto a substructure, following manufacturer guidelines for secure mounting.

4. Can the panels be curved?

Absolutely. Their composite nature allows for cold bending to create curved architectural features.

5. How do you clean and maintain them?

Easy maintenance typically requires only occasional washing with water and a mild, non-abrasive detergent.

5 FAQs of Metal Composite Sandwich Panel: Combines Both Metal Compositeand Sandwich Properties, Highly Versatile

What is a metal composite sandwich panel?

It is a building material made of two thin metal sheets bonded to a lightweight core. The metal layers give strength and durability. The core adds insulation and keeps the panel light.

Why choose this panel over other materials?

It offers both the toughness of metal and the lightness of a sandwich structure. This makes it easy to handle and install. It also resists weather, corrosion, and fire better than many alternatives.

Where can you use these panels?

They work well on building facades, roofs, walls, and ceilings. They are common in offices, airports, shopping centers, and industrial buildings. Their design flexibility suits both modern and traditional styles.

How long do these panels last?

With proper care, they can last 20 years or more. The metal surface protects against rust and damage. The core stays stable under normal conditions. Regular cleaning helps maintain appearance and performance.

Are they eco-friendly?

Yes. Most panels use recyclable aluminum. The production process saves energy compared to solid metal sheets. Their insulating core reduces heating and cooling needs in buildings. This lowers overall energy use over time.

(Metal Composite Sandwich Panel: Combines Both Metal Compositeand Sandwich Properties, Highly Versatile)