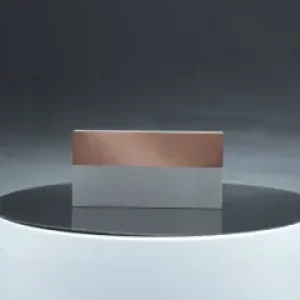

Overview of Single Fold Copper Coated Micro Steel Fiber Reinforced for Concrete Construction Materials

Single Fold Copper Coated Micro Steel Fiber Reinforced for Concrete Construction Materials is an innovative building material that seamlessly bonds a copper veneer to a robust steel core. This fusion creates a panel that combines the timeless, elegant aesthetic of copper with the exceptional strength and durability of steel. It is engineered for high-performance architectural cladding and signage, offering a premium, long-lasting solution for modern construction and design projects.

Features of Single Fold Copper Coated Micro Steel Fiber Reinforced for Concrete Construction Materials

- Dual-Material Advantage: Marries the classic, evolving patina of copper with the structural rigidity and impact resistance of steel.

- Lightweight & Easy to Install: Significantly lighter than solid copper or steel plates, simplifying handling and reducing structural support costs.

- Exceptional Flatness: The composite construction ensures a consistently smooth, ripple-free surface for a flawless appearance.

- Weather & Corrosion Resistance: Offers outstanding durability against the elements, with the copper surface providing natural protective oxidation over time.

- Flexible Fabrication: Can be easily cut, bent, and shaped to meet complex architectural designs and custom specifications.

Applications of Single Fold Copper Coated Micro Steel Fiber Reinforced for Concrete Construction Materials

Ideal for exterior and interior applications where beauty and resilience are paramount. Common uses include:

- Architectural facades, cladding, and curtain walls

- Soffits, canopies, and column covers

- High-end interior feature walls and accents

- Durable and distinctive signage and branding elements

- Renovation projects for a modern, premium upgrade

(Single Fold Copper Coated Micro Steel Fiber Reinforced for Concrete Construction Materials)

Parameters of Single Fold Copper Coated Micro Steel Fiber Reinforced for Concrete Construction Materials

Solitary fold copper covered micro steel fiber is an unique additive for concrete. It aids make concrete stronger and more long lasting. The fibers are made from high carbon steel. Each fiber has a thin layer of copper on its surface. This copper finishing quits rust and aids the fiber bond well with the concrete mix.

The fibers are brief and thin. Their common size is in between 6 mm and 13 mm. The diameter normally varies from 0.15 mm to 0.20 mm. Every fiber has a solitary bend near the middle. This form assists the fiber hold firmly inside the concrete. It likewise stops the fiber from clumping throughout mixing.

These fibers function well in many kinds of concrete tasks. They are used in commercial floors, tunnel linings, precast parts, and shotcrete. Including them reduces splits brought on by shrinkage. They also boost effect resistance and sturdiness. The concrete progresses at dealing with sudden loads or anxiety.

You add the fibers straight right into the mixer with other materials. No additional actions are required. The recommended dosage is typically 20 to 40 kilograms per cubic meter of concrete. This amount offers good results without making the mix difficult to deal with.

The copper layer sees to it the fibers remain protected gradually. It likewise aids them spread equally in the mix. Due to this, the final concrete item lasts longer and requires much less repair. Home builders and designers choose this fiber when they need trusted efficiency and straightforward use.

This sort of fiber satisfies worldwide standards for top quality and safety and security. It is tested for tensile strength, facet ratio, and finishing density. All these factors guarantee it functions as expected in real-world problems. Specialists locate it simple to utilize and reliable in improving concrete behavior.

(Single Fold Copper Coated Micro Steel Fiber Reinforced for Concrete Construction Materials)

Applications of Single Fold Copper Coated Micro Steel Fiber Reinforced for Concrete Construction Materials

Solitary fold copper covered mini steel fiber is a solid enhancement to concrete. It aids make concrete tougher and a lot more long lasting. Contractors mix these little steel fibers into damp concrete before it establishes. The copper finish quits the steel from rusting inside the concrete. This maintains the product strong for several years.

Concrete with this fiber handles stress better. It resists cracks that typically develop under heavy loads or abrupt impacts. Roads, bridges, and commercial floorings use this mix since they encounter consistent wear. The fibers hold the concrete with each other also when little splits start. This implies less repairs and longer life span.

Tunnels and underground structures additionally profit. These places require materials that stay undamaged under stress. The fibers improve exactly how well the concrete bends without breaking. They add adaptability while maintaining strength high. Parking garages and storage facility slabs utilize this kind of concrete too. Hefty cars drive over them daily. The fibers aid the surface area stay smooth and secure.

Precast concrete parts like pipes or panels gain extra strength with these fibers. Manufacturing facilities include them during manufacturing. The result is a product that ships and sets up with much less threat of damages. Also thin sections stay strong since the fibers spread equally with the mix.

Builders similar to this option since it works with basic mixing techniques. No unique tools are required. The fibers blend in quick and stay uniformly spread. This saves time on website. It additionally lowers the demand for conventional rebar sometimes. That lowers labor prices and quicken job.

In general, single layer copper coated mini steel fiber provides concrete a clear boost. It makes structures more secure, harder, and much more trusted in daily usage.

Company Profile

Metal Plate 4 U is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Copper Steel Composite Panel

1. How does the patina (weathering) of the copper surface affect the panel?

The natural patina formation is a desirable feature, creating a beautiful, protective layer that enhances corrosion resistance and adds character over time. The rate can vary based on local environmental conditions.

2. Is the panel suitable for coastal or high-humidity environments?

Yes. The inherent properties of copper and the protective coating on the steel core provide excellent resistance to salt spray and moisture, making it a suitable choice for such applications.

3. Can the panels be curved or formed into specific shapes?

Absolutely. The composite construction allows for good formability. Panels can be cold-curved or fabricated into various shapes to meet specific design requirements.

4. What are the installation and maintenance requirements?

Installation follows standard practices for composite panels using appropriate mechanical fixing systems. Maintenance is minimal, typically requiring only occasional cleaning with water and a mild detergent.

5. How does the cost compare to solid copper panels?

Copper Steel Composite Panels offer a considerable cost advantage over solid copper, providing the same prestigious look with reduced material weight, easier installation, and often lower overall project costs.

5 FAQs of Single Fold Copper Coated Micro Steel Fiber Reinforced for Concrete Construction Materials

What is single fold copper coated micro steel fiber?

It is a tiny steel fiber used in concrete. The fiber has one bend and a thin copper layer on its surface. This design helps it mix well into concrete and stick strongly to the cement paste.

Why add copper coating to the steel fiber?

The copper coating stops rust from forming too early. It also makes the fiber easier to spread evenly in the mix. Better distribution means better performance in the hardened concrete.

How does this fiber improve concrete?

It boosts toughness and reduces cracking. When concrete starts to crack, the fibers hold the pieces together. This gives the structure more ductility and impact resistance compared to plain concrete.

What construction projects use this fiber?

It works well in industrial floors, tunnel linings, precast elements, and shotcrete applications. Any place that needs higher durability or thinner sections can benefit from this fiber.

How much fiber should be added to concrete?

Typical dosage ranges from 20 to 50 kilograms per cubic meter of concrete. The exact amount depends on the project’s strength needs and the type of structure being built. Always follow the supplier’s guidelines or run small tests first to find the best mix.

(Single Fold Copper Coated Micro Steel Fiber Reinforced for Concrete Construction Materials)