Overview of The Steel-copper-steel Composite bar JKDDKF-85144 for Rail Transit Has a High Bonding Strength

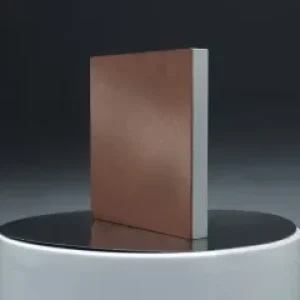

The Steel-copper-steel Composite bar JKDDKF-85144 for Rail Transit Has a High Bonding Strength is an innovative building material that seamlessly bonds a copper veneer to a robust steel core. This fusion creates a panel that combines the timeless, elegant aesthetic of copper with the exceptional strength and durability of steel. It is engineered for high-performance architectural cladding and signage, offering a premium, long-lasting solution for modern construction and design projects.

Features of The Steel-copper-steel Composite bar JKDDKF-85144 for Rail Transit Has a High Bonding Strength

- Dual-Material Advantage: Marries the classic, evolving patina of copper with the structural rigidity and impact resistance of steel.

- Lightweight & Easy to Install: Significantly lighter than solid copper or steel plates, simplifying handling and reducing structural support costs.

- Exceptional Flatness: The composite construction ensures a consistently smooth, ripple-free surface for a flawless appearance.

- Weather & Corrosion Resistance: Offers outstanding durability against the elements, with the copper surface providing natural protective oxidation over time.

- Flexible Fabrication: Can be easily cut, bent, and shaped to meet complex architectural designs and custom specifications.

Applications of The Steel-copper-steel Composite bar JKDDKF-85144 for Rail Transit Has a High Bonding Strength

Ideal for exterior and interior applications where beauty and resilience are paramount. Common uses include:

- Architectural facades, cladding, and curtain walls

- Soffits, canopies, and column covers

- High-end interior feature walls and accents

- Durable and distinctive signage and branding elements

- Renovation projects for a modern, premium upgrade

(The Steel-copper-steel Composite bar JKDDKF-85144 for Rail Transit Has a High Bonding Strength)

Parameters of The Steel-copper-steel Composite bar JKDDKF-85144 for Rail Transit Has a High Bonding Strength

The steel-copper-steel composite bar JKDDKF-85144 is constructed for rail transit systems. It has a solid bond between its layers. The external layers are constructed from high-strength steel. The internal core is pure copper. This framework provides the bar great electrical conductivity and mechanical stamina. The bonding stamina in between the steel and copper layers is very high. It stays stable under heavy tons and repeated stress and anxiety.

This composite bar functions well in overhead get in touch with lines. It brings electric existing to drive train. The copper core guarantees reduced electrical resistance. The steel layers include tensile strength and toughness. With each other, they withstand wear, corrosion, and tiredness. Bench keeps performing even in harsh weather condition or high-traffic problems.

Producers utilize a special procedure to join the steel and copper. This creates a tight, consistent bond without voids or vulnerable points. The interface remains strong gradually. It does not separate throughout bending, extending, or thermal cycling. That makes bench trustworthy for lasting use.

The measurements of the JKDDKF-85144 fulfill standard rail sector needs. Its surface is smooth and tidy. There are no splits, burrs, or surface area defects. Quality checks occur at every manufacturing phase. Each batch is tested for bonding strength, conductivity, and mechanical buildings.

Rail operators pick this composite bar since it lasts longer than single-material alternatives. It decreases maintenance requirements and downtime. The solid bond implies fewer failings in service. It fits quickly right into existing rail framework. Installation and substitute are simple. Bench supports reliable, secure train procedures throughout numerous sorts of rail networks.

(The Steel-copper-steel Composite bar JKDDKF-85144 for Rail Transit Has a High Bonding Strength)

Applications of The Steel-copper-steel Composite bar JKDDKF-85144 for Rail Transit Has a High Bonding Strength

The steel-copper-steel composite bar JKDDKF-85144 is constructed for rail transportation systems. It has a strong bond in between its layers. This bond remains strong also under heavy anxiety and constant movement. The bar utilizes copper in the center with steel on both sides. This layout offers it great electric conductivity from the copper and high strength from the steel. Rail transit systems need components that handle both mechanical lots and electric present. This bar meets both needs well.

It works well in overhanging call lines. These lines bring power to trains. The copper core helps power flow efficiently. The steel layers include longevity and assistance. Bench stands up to wear from pantographs and climate. It additionally handles temperature level modifications without shedding efficiency. Installation is easy because the bar keeps its sizes and shape gradually.

Maintenance prices drop when this bar is used. It lasts longer than many typical materials. Less substitutes imply less downtime for railway. Security boosts also since bench minimizes the threat of electric faults or architectural failure. It matches existing rail facilities without significant changes. Designers can use it in new builds or upgrades.

The bonding strength of JKDDKF-85144 is evaluated under real-world conditions. It stands up against vibration, tension, and thermal cycling. No delamination occurs in between the steel layers. This dependability matters for busy urban transportation networks. Trains run on limited schedules. Any kind of part failing can cause hold-ups. Utilizing this composite bar assists maintain service working on time.

Rail operators pick this bar for its balance of feature and expense. It carries out far better than single-material choices in most cases. The mix of steel and copper offers it an edge where both toughness and conductivity matter.

Company Profile

Metal Plate 4 U is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality metal clad and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal alloy clad and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Copper Steel Composite Panel

1. How does the patina (weathering) of the copper surface affect the panel?

The natural patina formation is a desirable feature, creating a beautiful, protective layer that enhances corrosion resistance and adds character over time. The rate can vary based on local environmental conditions.

2. Is the panel suitable for coastal or high-humidity environments?

Yes. The inherent properties of copper and the protective coating on the steel core provide excellent resistance to salt spray and moisture, making it a suitable choice for such applications.

3. Can the panels be curved or formed into specific shapes?

Absolutely. The composite construction allows for good formability. Panels can be cold-curved or fabricated into various shapes to meet specific design requirements.

4. What are the installation and maintenance requirements?

Installation follows standard practices for composite panels using appropriate mechanical fixing systems. Maintenance is minimal, typically requiring only occasional cleaning with water and a mild detergent.

5. How does the cost compare to solid copper panels?

Copper Steel Composite Panels offer a considerable cost advantage over solid copper, providing the same prestigious look with reduced material weight, easier installation, and often lower overall project costs.

5 FAQs of The Steel-copper-steel Composite bar JKDDKF-85144 for Rail Transit Has a High Bonding Strength

What is the JKDDKF-85144 composite bar made of?

It uses a steel-copper-steel layered structure. The outer layers are steel. The middle layer is copper. This design gives it good mechanical strength and electrical conductivity.

Why is bonding strength important for this bar?

Strong bonding keeps the three layers stuck together under stress. Rail transit systems need parts that hold up over time. Weak bonding could cause delamination or failure. This bar has high bonding strength to avoid those problems.

How does this bar perform in rail transit applications?

It works well in grounding and current return systems. The copper layer carries electricity efficiently. The steel layers add durability and protect the copper. It handles vibration, temperature changes, and mechanical loads common in trains and tracks.

Is this composite bar corrosion resistant?

Yes. The steel used is treated to resist rust. Copper also resists corrosion naturally. Together, they last longer in outdoor and humid environments typical of rail systems.

Can this bar be welded or connected easily?

It can be welded using standard methods for steel. The strong bond between layers stays intact during welding. Electrical connections can be made without damaging the structure. This makes installation and maintenance simpler for rail engineers.

(The Steel-copper-steel Composite bar JKDDKF-85144 for Rail Transit Has a High Bonding Strength)