1. Introduction

Just 24 hours ago, the American Institute of Architects highlighted a surge in sustainable commercial projects using weathering steel and recycled metal cladding—underscoring how ‘metal clad’ systems are reshaping modern design with durability and eco-efficiency. Whether you’re renovating a home, specifying materials for a build, or simply curious about construction terms, understanding metal clad is more relevant than ever.

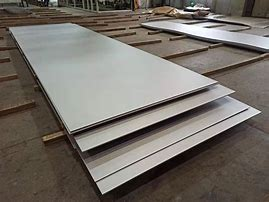

At its core, ‘metal clad‘ refers to any structure, component, or surface that’s covered or layered with metal for protection, aesthetics, or performance. The term spans everything from a metal clad roof on a backyard shed to high-end clad metals used in aerospace engineering.

2. What Does ‘Metal Clad’ Mean?

The phrase ‘metal clad meaning’ often confuses newcomers—but it’s straightforward. ‘Clad’ means to cover or sheath. So, ‘metal clad’ describes an object wrapped in metal. Similarly, ‘clad metal meaning’ refers to a composite material: a base metal (like steel) bonded with a more corrosion-resistant layer (like stainless steel or copper).

This technique enhances strength, longevity, and appearance without the full cost of solid premium metal. You’ll see it in everything from kitchen cookware to industrial piping.

3. Metal Clad in Architecture

Architects love metal cladding for its sleek look and resilience. A metal clad wall or metal facade can transform a dull box into a striking statement—especially with materials like corten steel siding, zinc metal siding, or copper siding.

Popular choices include:

- Corten steel facade: Rustic, self-protecting, and low-maintenance. Corten steel siding cost varies but offers long-term value.

- Zinc clad roof or zinc clad dormer: Elegant, naturally patinas over time, and highly recyclable.

- Colorbond standing seam or PAC Clad standing seam roof: Durable, watertight, and ideal for modern metal clad houses.

- Vertical standing seam metal siding: Clean lines, excellent for contemporary steel clad buildings.

Corrugated steel facade and exterior corrugated metal siding remain favorites for industrial and rustic designs—blending function with raw aesthetic appeal.

4. Common Metal Clad Building Materials

Beyond looks, performance matters. Many builders choose specific clad metals based on climate, budget, and use case.

Steel clad systems often use aluminum clad steel or stainless clad aluminum for corrosion resistance. Aluminum clad sheet (or aluminium clad sheet) is lightweight and ideal for wall panels or roofing.

For high-end projects, you might see titanium clad surfaces or zinc and nickel alloy coatings. Even boiler plate steel gets upgraded with zinc coated or chromium electroplating for outdoor use.

Don’t forget practical elements like PAC Clad coping, column covers, or metal weatherboard—all designed to protect edges and joints while maintaining visual continuity.

5. Metal Clad in Electrical and Industrial Applications

Not all metal clad is architectural. Metal clad electrical wire (also called MC cable) is widely used in commercial buildings—including in Pennsylvania—thanks to its armored protection.

Types include:

- Aluminum clad wire or aluminum clad steel wire: Good conductivity with added strength.

- CU clad wire: Copper-clad for better performance at lower cost.

- Metal clad wire for outdoor or surface-mounted runs: Permitted when properly rated.

In piping, aluminum clad pipe insulation helps maintain temperature while resisting damage. Meanwhile, metal clad insulation is common in HVAC and industrial settings.

6. Understanding Clad Metals and Plates

Clad metals merge the best of two worlds. Examples include aluminum clad stainless steel (strong base + corrosion-resistant skin) or copper nickel clad for marine environments.

When it comes to plates, the market offers everything from 1/8 inch steel plate to thick steel plate in grades like 316 stainless steel plate or 6061 T6 aluminum plate. Diamond plate steel, checker plate metal sheet, and perforated plate serve specialized needs—from slip resistance to filtration.

You’ll also find alloy clad options like 2024 T3 clad or 7075 T6 clad in aerospace, where strength-to-weight ratio is critical. Inconel weld overlay and chrome carbide overlay extend equipment life in extreme conditions.

7. Choosing the Right Metal Clad Type

With so many options, how do you pick? Consider:

- Environment: Coastal areas favor stainless steel plate or zinc metal siding.

- Budget: Corten siding cost is higher upfront but lower long-term; corrugated steel is economical.

- Aesthetics: Copper siding ages beautifully; PAC Clad HWP offers clean, modern lines.

- Function: Need fire resistance? Go for steel clad. Electrical safety? Use properly rated metal clad cable.

Always verify local codes—especially for metal clad wiring in commercial builds.

8. Conclusion

From the sleek steel facade of a downtown office to the humble metal clad shed in your backyard, metal cladding is versatile, durable, and increasingly sustainable. Whether you’re exploring clad metals for engineering or picking siding for your metal clad house, understanding the options—from corten steel plate to aluminum diamond tread plate—empowers smarter decisions. As green building trends accelerate, expect metal clad solutions to keep evolving, blending innovation with timeless performance.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Understand. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.