1. Introduction

Just 24 hours ago, global architecture firm Foster + Partners unveiled a new sustainable office complex in Copenhagen featuring a striking zinc clad roof and corten steel facade—reigniting interest in metal cladding as both an aesthetic and functional building solution. This timely spotlight makes it the perfect moment to dive deep into what ‘metal clad’ really means and why it’s everywhere—from skyscrapers to sheds.

Whether you’re a homeowner considering a metal clad house, a contractor working with metal clad electrical wire, or simply curious about clad steel in industrial settings, this guide breaks it all down in plain English.

2. What Does ‘Metal Clad’ Mean?

At its core, ‘metal clad meaning’ refers to any product, structure, or material that has a metal layer bonded to another substrate for enhanced performance, durability, or appearance. The term ‘clad metals‘ describes composites like aluminum clad stainless steel or titanium clad sheets—where two or more metals are metallurgically bonded.

Don’t confuse ‘metal clad‘ with mere surface painting. True cladding involves fusion—often through rolling, explosion bonding, or electroplating—so the layers act as one. For example, aluminum clad steel wire combines conductivity with strength, while stainless clad aluminum offers corrosion resistance without full stainless cost.

3. Metal Clad in Architecture and Construction

3.1 Exterior Applications: Walls, Roofs, and Facades

Modern buildings increasingly use metal clad wall systems for their sleek look and low maintenance. Popular choices include corrugated steel facade panels, vertical standing seam metal siding, and corten steel siding—which develops a rustic, rust-like patina over time.

A metal clad roof isn’t just durable—it’s stylish. Options range from zinc clad roofs and copper siding to Colorbond standing seam and PAC Clad standing seam roof systems. These materials resist fire, pests, and extreme weather while offering decades of service life.

For accent features, designers often specify a zinc clad dormer or PAC Clad column covers to add texture and contrast. Even small elements like PAC Clad coping or metal weatherboard profiles contribute to a cohesive metal-clad aesthetic.

3.2 Cost and Material Considerations

Corten siding cost varies widely—typically $8–$15 per square foot installed—but delivers unmatched visual drama. Zinc metal siding and copper siding sit at the premium end, while exterior corrugated metal siding offers budget-friendly appeal without sacrificing longevity.

Homeowners exploring a steel clad house or metal clad shed should consider local climate, insulation needs, and long-term upkeep. Fortunately, many metal clad buildings now integrate metal clad insulation for improved energy efficiency.

4. Industrial and Technical Uses of Clad Metals

Beyond buildings, clad metals play critical roles in aerospace, chemical processing, and electronics. Alloy clad sheets like 2024 T3 clad or 7075 T6 clad aluminum combine high strength with corrosion resistance—ideal for aircraft skins.

In piping and wiring, aluminum clad pipe insulation protects against heat loss, while metal clad electrical wire (often called MC cable) shields conductors in commercial and industrial settings. Types include CU clad wire and aluminum clad wire—each suited to specific voltage and environmental demands.

Clad steel plates—such as boiler plate steel with a stainless overlay or chrome carbide plate for wear resistance—are essential in heavy machinery. Similarly, nickel brass clad copper and cupro nickel clad materials excel in marine environments due to their anti-corrosive properties.

5. Common Metal Plates and Sheets in Cladding Systems

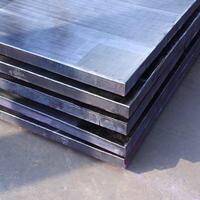

When fabricators source materials for metal cladding projects, they often choose from a wide catalog of metal plates and sheets:

- Stainless steel plate (including 316L SS plate and 304L variants)

- Aluminum diamond tread plate for slip-resistant surfaces

- Corten steel plate for weathering applications

- Mild steel plate or carbon steel plate for structural backing

- Perforated plate or diamond plate sheet metal for decorative screening

Thickness matters too—common specs include 1/8 inch steel plate, 3/16 metal plate, or 1/4 metal plate, depending on load and exposure requirements. Many suppliers now offer ‘steel plate near me’ delivery for fast project turnaround.

6. Finishing and Fabrication Techniques

Creating high-performance clad systems often involves advanced processes like electroplating, electroless nickel coating, or weld overlays (e.g., Inconel 625 weld overlay for extreme heat resistance). Chromium electroplating adds hardness, while gold coating may be used in electronics.

Metal sheet cutting services can precision-cut aluminum 6061 T6 plate, stainless steel 316 sheet, or alloy checker plate to exact dimensions—ensuring seamless integration into facades or enclosures.

7. Conclusion

From the zinc facade of a downtown loft to the aluminum clad stainless steel in your kitchen cookware, ‘metal clad’ is far more than a buzzword—it’s a versatile engineering and design strategy. Whether you’re choosing standing seam siding for your home or specifying clad metal for industrial use, understanding the options ensures smarter, longer-lasting decisions. As sustainability drives innovation, expect even more creative uses of metal clad systems in the years ahead.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Understand. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.