1. Introduction

Just 24 hours ago, the world’s largest sustainable architecture expo in Copenhagen spotlighted a new wave of buildings wrapped in innovative metal clad exteriors—from self-weathering corten steel facades to energy-efficient zinc clad dormers. These aren’t your grandfather’s corrugated sheds; today’s metal clad systems are engineering marvels blending form, function, and environmental responsibility.

Metal clad—often written as metalclad or referred to through terms like clad metals or clad metal meaning—is no longer limited to industrial sheds or electrical wiring. In high-end architecture, it’s become a go-to for designers seeking resilience, low maintenance, and bold visual impact.

2. Why Architects Are Choosing Metal Clad Facades

Modern architects increasingly specify metal clad wall systems because they offer unmatched longevity and design flexibility. Whether it’s a sleek standing seam facade or dramatic exterior corrugated metal siding, these materials resist corrosion, fire, and extreme weather.

- Corten steel siding develops a protective rust-like patina that eliminates the need for painting and repairs.

- Zinc metal siding is 100% recyclable and ages gracefully with a soft, matte finish.

- Copper siding evolves over time into rich green hues, adding historic charm to contemporary builds.

3. Advanced Applications in Sustainable Design

One standout trend is the use of pac clad standing seam roofs and pac clad column covers in net-zero energy buildings. These systems integrate seamlessly with solar panels and rainwater harvesting setups while maintaining clean lines.

Similarly, a zinc clad roof isn’t just beautiful—it reflects heat better than asphalt shingles, reducing cooling loads in summer. Paired with metal clad insulation, these roofs contribute significantly to a building’s thermal envelope.

For coastal or high-humidity environments, aluminum clad steel offers superior salt resistance. This makes it ideal for seaside metal clad houses or marine research facilities where traditional materials would degrade quickly.

4. Beyond Aesthetics: Structural and Safety Benefits

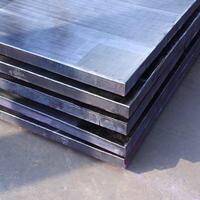

Metal clad isn’t just skin-deep. In structural terms, steel plate and stainless steel plate substrates provide rigidity and impact resistance. A metal clad building can withstand hurricanes, wildfires, and even seismic activity far better than wood or vinyl alternatives.

Electrical safety also benefits from metal clad innovations—metal clad electrical wire and aluminum clad wire meet stringent commercial codes (including in Pennsylvania) thanks to their armored sheathing that resists damage and contains faults.

Even interior elements leverage clad technology: stainless clad aluminum and aluminum clad stainless steel combine corrosion resistance with strength, useful in everything from HVAC ducts to kitchen equipment.

5. Material Innovations Driving the Trend

The rise of alloy clad systems—like 7075 T6 clad aluminum or copper nickel clad composites—has expanded possibilities. These hybrid materials merge the best properties of multiple metals without the cost of solid exotic alloys.

For example, titanium clad panels offer aerospace-grade performance at a fraction of pure titanium’s price. Meanwhile, electroplating techniques like chromium electroplating or electroless nickel enhance surface hardness and wear resistance on components like metal nameplates or diamond plate steel sheets.

Builders sourcing materials now search for ‘steel plate near me’ or ‘aluminum sheet for sale’ not just for raw stock—but for pre-finished clad options like colorbond standing seam or pac clad HWP (high-wind performance) panels.

6. Cost vs. Value: Is It Worth It?

Yes—especially long-term. While corten siding cost may seem high upfront (typically $8–$15 per sq. ft.), its 50+ year lifespan and zero maintenance offset repainting or replacement cycles of cheaper sidings.

Likewise, a steel clad house might cost 10–20% more initially than a standard build, but insurance premiums drop due to fire and storm resistance. Plus, resale value climbs with distinctive features like a corrugated steel facade or vertical standing seam metal siding.

7. Conclusion

From pac clad coping on penthouse rooftops to zinc clad dormers on eco-lofts, metal clad has evolved far beyond basic utility. Today’s clad metals merge sustainability, safety, and stunning design—making them indispensable in next-generation architecture. Whether you’re specifying a stainless steel metal plate for cladding or choosing between aluminum clad sheet and copper siding, one thing is clear: metal clad is here to stay.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Unlock. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.