1. Introduction

In the past 48 hours, a surge in sustainable architecture projects has spotlighted metal-clad exteriors as a go-to solution for modern, energy-efficient buildings. From New York to Sydney, developers are increasingly choosing metal clad facades—like corten steel siding and zinc clad roofs—for their durability, aesthetic appeal, and low maintenance. This growing trend reflects a broader shift toward resilient, recyclable building materials in the face of climate challenges.

So, what exactly is metal clad? Whether you’re a homeowner considering a steel clad house, a contractor working with metal clad electrical wire, or an engineer sourcing clad steel for industrial use, understanding the term is essential. Let’s break it down.

2. What Does Metal Clad Mean?

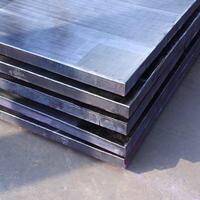

The term metal clad (sometimes written as metalclad) refers to a composite material or structure where one metal is bonded—mechanically, metallurgically, or through electroplating—to another for enhanced performance. This process, known as cladding, combines the strength, corrosion resistance, or conductivity of different metals into a single, functional unit.

Clad metal meaning varies by context. In construction, it often describes exterior surfaces like metal clad wall panels or metal clad siding. In manufacturing, it might refer to aluminum clad stainless steel sheets or copper-clad wires. The core idea remains the same: layering metals to get the best of both worlds.

3. Common Types of Metal Clad Applications

Metal clad isn’t just one thing—it shows up in countless forms across industries.

- Metal clad buildings use steel plate or corrugated steel facade systems for warehouses, sheds, and even luxury homes.

- Metal clad roofs, such as colorbond standing seam or pac clad standing seam roof systems, offer longevity and sleek design.

- Metal clad electrical wire (like aluminum clad steel wire or cu clad wire) is used in commercial and industrial settings for its durability and fire resistance.

- In piping, aluminum clad pipe insulation protects against heat loss and corrosion.

- Architectural features like pac clad column covers, pac clad coping, and zinc clad dormers blend function with modern aesthetics.

4. Popular Materials in Metal Cladding

Different projects call for different metals. Here’s a look at some of the most widely used:

Corten steel is famous for its rust-like appearance that stabilizes over time. Corten steel facade and corten steel siding are increasingly popular in contemporary design—though corten siding cost can be higher than standard options.

Zinc offers a self-healing patina and is used in zinc facade, zinc metal siding, and zinc clad roof installations. It’s prized for sustainability and low upkeep.

Copper siding ages beautifully, developing a green patina that architects love for historic or high-end builds.

Aluminum—lightweight and corrosion-resistant—is common in aluminum clad sheet, aluminum clad steel, and vertical standing seam metal siding. You’ll also find it in aluminum diamond tread plate for industrial flooring.

Stainless steel appears in everything from stainless steel plate grades (like 316L or 304L) to stainless clad aluminum composites for chemical processing equipment.

5. Industrial and Specialty Clad Metals

Beyond architecture, clad metals play a critical role in heavy industry and electronics.

Alloy clad materials—such as 2024 T3 clad aluminum or 7075 T6 clad—are used in aerospace for their strength-to-weight ratios.

Exotic combinations like titanium clad, inconel 625 overlay, or nickel brass clad copper serve extreme environments like oil refineries or nuclear plants.

Electroplating techniques (e.g., chromium electroplating, electroless nickel, or gold coating) create thin but effective protective layers on base metals like mild steel plate or brass plates for engraving.

Perforated plate, diamond plate steel, and checker plate metal sheet (including aluminum checker plate and stainless steel diamond plate) are often clad or coated for added resilience in transport and marine applications.

6. Choosing the Right Metal Clad Type

Selecting the right metal clad type depends on your project’s needs. For a metal clad house, consider weather resistance, aesthetics, and local climate—standing seam facade systems in aluminum or steel perform well in rain and snow.

For industrial use, factors like temperature tolerance, chemical exposure, and mechanical stress matter. Boiler plate steel or chrome carbide overlay plates may be necessary for high-wear zones.

When sourcing materials, terms like ‘steel plate for sale,’ ‘aluminum sheet for sale,’ or ‘stainless steel plate distributors’ can help you locate the right suppliers. Always verify specs like thickness (e.g., 1/8 inch steel plate, 3/16 metal plate) and alloy grade (e.g., 6061 T6 aluminum plate, 316 stainless steel plate).

7. Conclusion

Metal clad is far more than just a buzzword—it’s a versatile, high-performance solution spanning architecture, infrastructure, and advanced manufacturing. Whether you’re installing exterior corrugated metal siding, specifying clad metals for a refinery, or wiring a commercial building with metal clad cable, understanding the options ensures better outcomes. As sustainability and durability drive future design, expect metal clad systems—from corten steel plates to pac clad hwp profiles—to remain at the forefront of innovation.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.