1. Introduction

If you’ve ever admired a sleek modern office with shimmering panels or noticed a rustic yet sturdy home wrapped in weathered steel, you’ve likely seen metal clad in action. But what exactly does ‘metal clad’ mean? At its core, metal clad refers to any structure, component, or surface that’s covered or layered with metal for protection, aesthetics, or performance. From metal clad walls and roofs to specialized industrial materials like clad metals and metal clad electrical wire, this versatile technique spans architecture, engineering, and manufacturing. In this guide, we’ll unpack the metal clad meaning, explore its many forms—from corten steel siding to pac clad standing seam roofs—and explain why it’s become a go-to solution for durability and design.

2. Understanding Clad Metal Meaning

The term ‘clad metal meaning’ describes a composite material made by bonding two or more different metals together. This process enhances properties like corrosion resistance, strength, or conductivity while keeping costs manageable. For example, aluminum clad stainless steel combines the lightweight nature of aluminum with the toughness of stainless steel. Similarly, copper nickel clad or titanium clad materials are used in demanding environments like marine or aerospace applications. Clad metals can be created through methods like roll bonding, explosion welding, or electroplating—where a thin layer of one metal (like chromium or gold) is deposited onto another. Whether it’s stainless clad aluminum for cookware or nickel brass clad copper for electrical components, clad metals offer the best of both worlds.

3. Metal Clad in Architecture and Building Design

In construction, ‘metal clad‘ most commonly refers to exterior building systems that use metal panels or sheets as a protective and decorative skin. A metal clad building might feature a metal clad roof, metal clad wall, or even a full metal facade. Popular choices include corrugated steel facade for industrial charm, zinc metal siding for minimalist elegance, and corten steel siding for that distinctive rusted-but-stable look. Corten steel siding cost varies based on thickness and finish, but its low maintenance and dramatic aging process make it a favorite for modern homes and commercial spaces. Other trending options include copper siding, which develops a green patina over time, and colorbond standing seam systems known for clean lines and weather resistance.

4. Common Types of Metal Cladding Systems

There’s no one-size-fits-all when it comes to metal cladding. Designers and builders choose based on climate, budget, and aesthetic goals. Standing seam siding—especially vertical standing seam metal siding—is prized for its watertight seams and contemporary appearance. Brands like PAC Clad offer systems such as pac clad hwp (horizontal wall panel), pac clad coping, and pac clad column covers that integrate seamlessly into modern facades. Zinc clad dormers and zinc clad roofs provide longevity with minimal upkeep, while exterior corrugated metal siding delivers a rugged, utilitarian vibe perfect for sheds or farmhouses. For those seeking a traditional look with modern performance, metal weatherboard or aluminum clad sheet options mimic wood but resist rot and pests.

5. Industrial and Technical Applications of Metal Clad

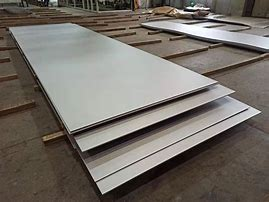

Beyond buildings, metal clad plays a critical role in infrastructure and manufacturing. Metal clad wire—such as aluminum clad steel wire or cu clad wire—is used in electrical transmission for its conductivity and strength. Aluminum clad pipe insulation protects HVAC and industrial piping from temperature extremes. In heavy industry, clad steel plates like boiler plate steel or carbon steel plate may be layered with stainless or nickel alloys to resist corrosion in chemical plants. Even everyday items like metal nameplates or diamond plate steel sheets (used for non-slip surfaces) often rely on clad or coated metals. Electroplating processes—like chromium electroplating or electroless nickel—add functional or decorative finishes to brass plates, aluminum tread plate, or mild steel plate.

6. Materials and Specifications You Should Know

The world of metal clad involves a vast array of base and cladding materials. Stainless steel plate grades like 316L or 304L are common for marine or medical environments, while alloy plates such as 6061 T6 aluminum plate or 7075 T6 clad serve aerospace needs. Thickness matters too—whether you’re sourcing 1/8 inch steel plate, 3/16 metal plate, or thick steel plate for structural bases. Perforated plate, checker plate metal sheet, and diamond plate sheet metal offer texture and grip. For buyers, terms like ‘steel plate for sale,’ ‘aluminum sheet for sale,’ or ‘aluminium checker plate near me’ reflect the accessibility of these materials through distributors. Advanced composites like inconel 625 weld overlay or chrome carbide overlay push performance boundaries in extreme conditions.

7. Conclusion

Metal clad is far more than just a building trend—it’s a smart, adaptable solution that bridges form and function across countless industries. Whether you’re designing a steel clad house with a corten steel facade, specifying pac clad standing seam roof panels, or selecting aluminum clad stainless steel for industrial piping, understanding the clad metal meaning unlocks better decisions. With options ranging from economical corrugated steel to premium titanium clad systems, metal cladding continues to evolve—offering sustainability, resilience, and striking visual impact for projects big and small.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.