1. Introduction

If you’ve ever admired a sleek modern building with shimmering walls or a rustic home wrapped in weathered steel panels, you’ve likely seen metal clad in action. But what exactly does ‘metal clad’ mean? In simple terms, metal clad refers to a structure, component, or surface that’s covered or layered with metal for protection, durability, or aesthetic appeal.

From metal clad roofs and facades to clad steel pipes and electrical wires, this versatile technique is used across construction, manufacturing, and design. Let’s break it all down.

2. What Does Metal Clad Mean?

The term ‘metal clad’ (sometimes written as ‘metalclad’) describes any object or system where a base material is coated, bonded, or wrapped with a layer of metal. This process—known as cladding—enhances performance, corrosion resistance, or visual style.

Clad metals combine the strength or cost-efficiency of a core material with the superior surface properties of another metal. For example, aluminum clad steel offers the affordability of steel with the rust resistance of aluminum.

- Common examples include stainless clad aluminum, titanium clad sheets, and copper nickel clad alloys.

- In construction, ‘metal clad wall,’ ‘metal clad roof,’ and ‘metal facade’ are frequent applications.

3. Metal Cladding in Architecture

Architects love metal cladding for its durability, low maintenance, and striking looks. Whether it’s a minimalist office tower or a cozy metal clad house, exterior metal systems define modern design.

Popular choices include corrugated steel facade panels, standing seam siding, and vertical standing seam metal siding. These not only look sharp but also handle harsh weather with ease.

Corten steel siding has surged in popularity thanks to its rust-like appearance that stabilizes over time—no painting needed. While corten siding cost can be higher upfront, its longevity often justifies the investment.

Other stylish options:

- Zinc metal siding and zinc clad roof systems offer a soft gray patina that evolves beautifully.

- Copper siding develops a greenish verdigris over decades, adding historic charm.

- Colorbond standing seam and PAC Clad standing seam roof systems provide pre-finished, long-lasting color options.

Even small features like a zinc clad dormer or PAC Clad column covers can elevate a building’s curb appeal.

4. Industrial and Engineering Uses of Clad Metals

Beyond buildings, clad metals are essential in heavy industry. Clad steel—such as stainless steel plate bonded to carbon steel—delivers corrosion resistance where it matters most, like in chemical plants or marine environments.

Aluminum clad stainless steel and stainless clad aluminum are used in heat exchangers and food processing equipment. Alloy clad variants like 2024 T3 clad or 7075 T6 clad serve aerospace needs by combining strength with lightweight properties.

Specialized products include:

- Aluminum clad pipe insulation for thermal efficiency.

- Metal clad wire and aluminum clad steel wire for electrical conductivity and strength.

- CU clad wire (copper-clad) for cost-effective wiring solutions.

Electroplating processes like chromium electroplating or electroless nickel further enhance surface properties, creating chrome metal finishes or wear-resistant nickel plates.

5. Metal Clad in Everyday Structures

You don’t need a skyscraper to benefit from metal cladding. Sheds, garages, and backyard studios often use metal clad siding for affordability and resilience.

A metal clad shed might feature exterior corrugated metal siding or metal weatherboard panels. These materials resist rot, pests, and fire—making them ideal for storage or workshops.

For homeowners, steel clad houses blend ruggedness with modern aesthetics. Companies like Steel Clad Inc specialize in prefab steel clad building systems that go up fast and last decades.

Even details matter: PAC Clad coping caps roof edges neatly, while aluminum clad sheet or aluminium clad sheet options offer flexibility for custom trims and flashings.

6. Understanding Metal Plates and Sheets

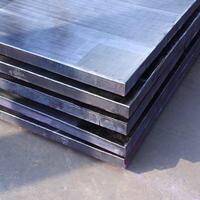

Many clad systems start with base metal plates. Options range from mild steel plate and boiler plate steel to high-performance alloys like Inconel 718 plate or titanium alloy plate.

Common thicknesses include 1/8 inch steel plate, 3/16 metal plate, and 1/4 steel plate—each suited to different load and environmental demands.

Surface variations like diamond plate steel, checker plate metal sheet, or perforated plate add slip resistance or visual interest. Aluminum diamond tread plate is popular for truck beds and stairs, while stainless steel checker plate works well in hygienic settings.

When sourcing materials, people often search for ‘steel plate near me’ or ‘aluminum sheet for sale’—highlighting the accessibility of these foundational components.

7. Electrical and Safety Applications

Metal clad isn’t just about looks—it’s critical for safety too. Metal clad electrical wire (often called MC cable) features a protective metal sheath, making it ideal for commercial buildings, including in states like Pennsylvania where code compliance is strict.

This type of wiring resists physical damage and electromagnetic interference. It can be surface-mounted and is commonly used in offices, hospitals, and industrial facilities.

Note: While metal clad cable is robust, proper installation—including correct box connections and grounding—is essential for safety and code adherence.

8. Conclusion

Metal clad is far more than a buzzword—it’s a smart, versatile solution across architecture, engineering, and everyday construction. Whether you’re choosing corten steel facade panels for a bold home exterior, specifying clad steel for an industrial tank, or running metal clad wire through a commercial wall, understanding the options ensures better performance and value.

With innovations in materials like PAC Clad HWP, alloy clad composites, and sustainable finishes, metal cladding continues to evolve—proving that sometimes, the best protection really is a good metal skin.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.