1. Introduction

If you’ve ever admired a sleek modern building with shimmering surfaces or driven past a rustic yet striking home wrapped in weathered steel, you’ve likely seen metal clad in action. But what exactly does ‘metal clad’ mean? In simple terms, metal clad refers to any structure, component, or surface that’s covered or ‘clad’ with a layer of metal for protection, aesthetics, or performance. From metal clad roofs and walls to metal clad electrical wire and insulated pipes, this versatile technique spans construction, manufacturing, and even cookware. Whether you’re a homeowner, architect, contractor, or curious DIYer, understanding metal clad—and its many forms like clad steel, corten steel facade, or aluminum clad sheet—can help you make smarter design and material choices.

2. What Does ‘Metal Clad’ Mean?

The term ‘metal clad’ (sometimes written as ‘metalclad’) broadly describes a composite material or finished product where one metal is bonded to another—either mechanically, metallurgically, or through processes like electroplating. This creates ‘clad metals’ that combine the best properties of each layer: strength from a base metal like carbon steel, and corrosion resistance from a surface layer like stainless steel or zinc. The ‘clad metal meaning’ isn’t just about looks—it’s functional engineering. For example, aluminum clad stainless steel offers lightweight durability, while stainless clad aluminum enhances thermal conductivity with rust resistance. These combinations are essential in everything from aerospace components to kitchen pans labeled ‘All-Clad.’

3. Metal Cladding in Architecture and Building Design

In construction, ‘metal cladding’ typically refers to exterior coverings applied to walls or roofs. A metal clad building might feature a corrugated steel facade for an industrial vibe, or a refined zinc clad roof for minimalist elegance. Popular options include metal clad siding like vertical standing seam metal siding, colorbond standing seam panels, or exterior corrugated metal siding. Homeowners increasingly opt for a metal clad house not just for style but for longevity—metal resists fire, pests, and rot far better than wood or vinyl. Specific styles like corten steel siding add a dramatic, rust-like patina that evolves over time, though corten siding cost can be higher than standard alternatives. Other sought-after finishes include copper siding for warmth, zinc metal siding for subtle sheen, and pac clad standing seam roofs known for clean lines and weather-tight performance.

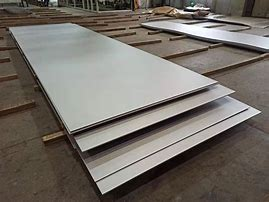

4. Common Types of Metal Clad Systems

Metal clad systems vary widely based on application. For walls, you’ll find metal clad wall panels made from aluminum clad sheet, stainless steel plate, or even titanium clad composites for high-end projects. Roofs often use pac clad coping, pac clad column covers, or pac clad hwp (horizontal wall panel) systems that integrate seamlessly with standing seam facade designs. Sheds and outbuildings frequently use metal clad shed panels—typically corrugated or ribbed steel—for affordability and quick installation. Meanwhile, metal weatherboard—a modern twist on traditional timber cladding—uses thin metal profiles to mimic classic aesthetics with superior durability. Don’t forget niche applications like zinc clad dormers or steel clad inc structural elements, which blend form and function in custom architecture.

5. Industrial and Technical Uses of Clad Metals

Beyond buildings, clad metals play critical roles in engineering. Aluminum clad steel wire and aluminum clad pipe insulation are common in HVAC and electrical systems, offering conductivity with added protection. Metal clad electrical wire—often armored with a flexible steel sheath—is widely used in commercial settings, including Pennsylvania, where code compliance matters. In heavy industry, you’ll encounter boiler plate steel, mild steel plate, or thick steel plate layered with corrosion-resistant alloys like Inconel 625 overlay for extreme environments. Electroplating techniques—such as chromium electroplating, electroless nickel, or gold coating—are used to create chrome metal finishes, nickel plates, or brass plates for engraving. Even metal nameplates often start as a stainless plate or aluminum diamond tread plate before customization.

6. Materials and Specifications You Should Know

When sourcing materials, terms like ‘steel plate price,’ ‘aluminum sheet for sale,’ or ‘stainless steel plate distributors’ come up often. Common grades include 316 stainless steel plate for marine resistance, 6061 T6 aluminum plate for structural use, and corten steel plate for architectural exteriors. Thicknesses matter too—whether you need 1/8 inch steel plate, 3/16 metal plate, or 1/4 metal plate for load-bearing bases. Perforated plate, diamond plate steel, and checker plate metal sheet (like aluminum checker plate or stainless steel checker plate) serve both decorative and anti-slip purposes. For high-performance needs, alloy plate options range from 7075 aluminum plate to Inconel 718 plate, often used in aerospace or chemical processing.

7. Conclusion

Metal clad is far more than a trend—it’s a smart, durable, and adaptable solution across countless industries. Whether you’re designing a steel clad house with a corten steel facade, installing metal clad wire in a commercial building, or selecting clad metals for industrial machinery, understanding the options—from aluminum clad steel to zinc nickel alloy overlays—ensures better performance and value. As materials science advances, expect even more innovative combinations like copper nickel clad or 2024 T3 clad aluminum to emerge. For now, metal clad remains a cornerstone of modern design and engineering, blending beauty, resilience, and functionality in one metallic package.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.