1. Introduction

Just 24 hours ago, a major architectural firm in Chicago unveiled a new mixed-use tower featuring a dramatic corten steel facade paired with vertical standing seam metal siding—a bold move that’s reigniting interest in durable, low-maintenance metal cladding systems. As cities push for sustainable, long-lasting building exteriors, understanding what ‘metal clad‘ really means—and how it varies across industries—is more relevant than ever.

At first glance, ‘metal clad‘ might seem like a single concept. But in reality, it spans everything from a zinc clad roof on a modern home to aluminum clad pipe insulation in refineries, and even metal clad electrical wire in commercial buildings. The term is context-dependent, so let’s break it down clearly.

2. What Does ‘Metal Clad’ Actually Mean?

The phrase ‘metal clad meaning’ often causes confusion because it’s used differently in construction, manufacturing, and electrical engineering. Broadly, ‘clad metal meaning’ refers to a composite material where one metal is bonded to another—typically for corrosion resistance, cost savings, or enhanced performance.

For example, aluminum clad steel combines the strength of steel with the corrosion resistance of aluminum. Similarly, stainless clad aluminum offers lightweight properties with surface durability. These are technically ‘clad metals,’ engineered through processes like roll bonding or explosion cladding—not just surface coatings like electroplating.

3. Metal Clad in Architecture: From Facades to Roofs

In architecture, ‘metal clad’ usually describes exterior finishes. A ‘metal clad wall’ or ‘metal facade’ can be made from various materials, each offering distinct aesthetics and performance traits.

- Corten steel siding creates a rust-like appearance that stabilizes over time, eliminating the need for painting. However, corten siding cost remains higher than alternatives—often $8–$15 per sq. ft., depending on thickness and finish.

- Zinc metal siding and zinc clad dormers offer self-healing patinas and 80+ year lifespans, popular in European design.

- Copper siding develops a green verdigris over decades and is prized for heritage projects.

- Exterior corrugated metal siding and corrugated steel facade options provide industrial charm at lower costs.

Roofing systems also leverage metal cladding. Colorbond standing seam and PAC Clad standing seam roofs dominate commercial builds due to their weather-tight seams and sleek profiles. PAC Clad HWP (High Wind Performance) variants are now standard in hurricane-prone zones, while PAC Clad coping and column covers complete the system aesthetically.

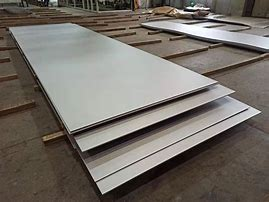

4. Industrial and Structural Clad Metals

Beyond buildings, ‘clad metals’ play a critical role in heavy industry. Boiler plate steel, carbon steel plate, and alloy plates like 6061 T6 aluminum or Inconel 718 are often clad to enhance functionality.

Examples include:

- Titanium clad steel for chemical reactors resisting extreme corrosion.

- Copper-nickel clad or cupro nickel clad tubes in marine heat exchangers.

- Chrome carbide overlay plates for mining equipment wear surfaces.

These aren’t just coated—they’re metallurgically bonded. Processes like hot rolling fuse layers permanently, unlike electroplating gold or chromium plate finishes, which are thin surface treatments.

Common base materials include mild steel plate, 316 stainless steel plate, or 5083 aluminum plate. Thicknesses range from 1/8 inch steel plate to thick steel plate over 2 inches, depending on structural demands.

5. Metal Clad in Electrical and Utility Applications

Here, ‘metal clad’ takes on a completely different meaning. Metal clad electrical wire (often called MC cable) features insulated conductors wrapped in an interlocked armor—usually aluminum or steel. It’s widely used in commercial buildings, including in Pennsylvania, where code permits surface-mounted installations.

Other electrical uses include:

- Aluminum clad wire for overhead transmission (lighter than pure copper).

- CU clad wire (copper-clad aluminum), balancing conductivity and weight.

- Metal clad insulation for pipes in high-temp environments.

Note: This has nothing to do with architectural ‘metal clad siding’—a frequent point of confusion. Also, AFIC breakers may still be required with MC cable, depending on local codes and circuit type.

6. Comparing Popular Metal Clad Types

Not all metal cladding is equal. Let’s compare key options:

- Steel clad vs. aluminum clad steel: Steel clad offers superior strength; aluminum clad steel resists rust better and weighs less.

- Stainless clad aluminum vs. aluminum clad stainless steel: The former prioritizes lightness with a stainless surface; the latter emphasizes corrosion resistance with an aluminum core.

- Corten steel plate vs. zinc plate: Corten weathers dramatically but can stain adjacent surfaces; zinc is cleaner and more uniform over time.

Even within categories, specs matter. A 3mm aluminium checker plate serves flooring needs, while a perforated plate might be used for acoustic panels. Diamond plate steel sheets add slip resistance in workshops, whereas brass plates for engraving serve decorative ID tags.

7. Conclusion

So, what is metal clad? It depends on your field. In architecture, it’s a stylish, resilient skin for buildings—from a steel clad house to a zinc clad roof. In industry, it’s high-performance composite plates like titanium clad or alloy clad sheets. In electrical work, it’s armored cabling for safety and durability.

Understanding these distinctions helps architects specify the right facade, engineers select proper clad metals, and electricians comply with code—all while avoiding mix-ups between terms like ‘aluminum clad sheet’ and ‘aluminum clad pipe insulation.’ As sustainable design pushes metal cladding into the spotlight, knowing your metal clad type ensures smarter, longer-lasting decisions.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.