1. Introduction

Just 24 hours ago, a major architectural firm in New York unveiled a new mixed-use tower featuring a striking corten steel facade—sparking renewed interest in metal clad exteriors among designers and developers. This trend underscores a broader shift toward resilient, low-maintenance, and visually distinctive building materials. But what exactly does ‘metal clad’ mean, and why is it gaining such momentum?

At its core, the metal clad meaning refers to any structure, component, or surface that is covered or ‘clad’ with a layer of metal. This technique is used across industries—from construction and electrical engineering to cookware and aerospace. Whether it’s a sleek metal clad house with vertical standing seam metal siding or industrial clad steel piping wrapped in aluminum clad pipe insulation, the principle remains the same: enhance performance, durability, or aesthetics through metal layering.

2. Understanding Clad Metals and Their Applications

Clad metals are composite materials made by bonding two or more different metals together. This process—often achieved through roll bonding, explosion bonding, or electroplating—combines the best properties of each metal. For example, aluminum clad stainless steel offers the corrosion resistance of stainless steel with the lightweight and cost benefits of aluminum. Similarly, copper nickel clad or titanium clad materials are used in marine and chemical environments where extreme durability is required.

Common types include stainless clad aluminum, aluminum clad steel, and even specialty combinations like nickel brass clad copper. These aren’t just lab curiosities—they’re found in everything from pac clad standing seam roofs to pac clad column covers in commercial buildings. The term ‘alloy clad’ also appears frequently, especially in aerospace contexts like 2024 T3 clad or 7075 T6 clad aluminum sheets used in aircraft skins.

3. Metal Clad in Architecture: Walls, Roofs, and Facades

One of the most visible uses of metal clad today is in building exteriors. A metal clad wall or metal facade can dramatically alter a structure’s appearance while offering weather resistance, fire protection, and longevity. Popular choices include corrugated steel facade panels, zinc metal siding, and copper siding for heritage-inspired designs.

Corten steel siding has surged in popularity thanks to its rust-like appearance that stabilizes over time, eliminating the need for painting. Though corten siding cost can be higher upfront—typically $8–$15 per square foot—it pays off in minimal maintenance. Similarly, a zinc clad roof or zinc clad dormer offers elegance and a lifespan exceeding 80 years. For modern homes, a steel clad house with colorbond standing seam or pac clad HWP panels delivers both style and storm resilience.

Standing seam systems—like vertical standing seam metal siding or pac clad coping—are especially favored for their clean lines and watertight performance. Meanwhile, exterior corrugated metal siding remains a go-to for metal clad sheds, barns, and industrial metal clad buildings.

4. Beyond Aesthetics: Functional Uses of Metal Clad

Not all metal clad applications are about looks. In electrical systems, metal clad electrical wire (often called MC cable) features insulated conductors wrapped in an interlocked metal sheath—typically aluminum or steel—for protection against physical damage and electromagnetic interference. Aluminum clad wire and cu clad wire are common variants used in commercial and residential wiring.

In industrial settings, metal clad insulation wraps pipes and ducts to maintain temperature and prevent condensation. Aluminum clad pipe insulation is standard in HVAC systems. Even metal nameplates on machinery often use clad metal meaning—thin layers of brass or stainless over cheaper substrates for engraving durability.

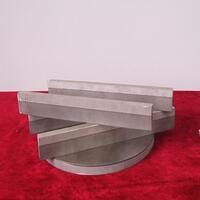

Then there’s the world of metal plates and sheets. From 1/8 inch steel plate to thick steel plate used in structural bases, these materials often serve as substrates for cladding. Stainless steel plate grades like 316L or 304L are chosen for corrosive environments, while aluminum diamond tread plate or checker plate metal sheet adds slip resistance in walkways and trucks.

5. Materials, Costs, and Considerations

Choosing the right metal clad type depends on budget, climate, and design goals. Corten steel plate offers weathering resistance but may stain adjacent surfaces. Zinc and copper develop patinas that many architects love—but come at a premium. Aluminum clad sheet is lightweight and recyclable, making it ideal for sustainable builds.

For those sourcing materials, terms like ‘steel plate for sale,’ ‘aluminum sheet for sale,’ or ‘aluminium checker plate near me’ often lead to suppliers offering everything from 6061 T6 aluminum plate to inconel 625 plate for high-temp applications. Prices vary widely: a 3/16 steel plate might cost $2–$4 per pound, while exotic alloys like titanium plate or inconel 718 plate can run 10x higher.

Electroplating also plays a role—chromium electroplating creates chrome metal finishes, while electroless nickel or nickel sulfamate coatings enhance wear resistance. Even gold coating appears in electronics via electroplating gold processes.

6. Conclusion

From the sleek steel facade of a downtown office to the humble metal clad shed in a backyard, metal clad solutions blend function and form like few other materials. Whether you’re specifying a corten steel siding cost for a boutique hotel or selecting aluminum clad steel wire for a retrofit project, understanding the breadth of clad metals—from boiler plate steel to pac clad standing seam roof systems—empowers smarter, more innovative decisions. As sustainability and durability drive construction forward, expect metal clad to remain front and center.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.