1. Introduction

Just 24 hours ago, a major storm system swept across the Midwest, leaving dozens of metal clad sheds and commercial buildings with dented siding and compromised seams. Homeowners are now scrambling to assess damage and prevent long-term issues like moisture intrusion and corrosion. If you own a metal clad house or building, knowing how to troubleshoot common problems is essential.

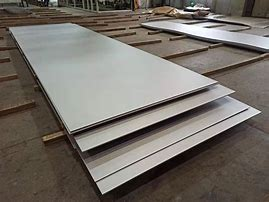

Metal clad systems—whether used for walls, roofs, or facades—offer durability, modern aesthetics, and low maintenance. But they’re not immune to wear, weather, or installation mistakes. In this guide, we’ll walk you through seven frequent issues and how to fix them, using real-world examples and practical tips.

2. Rust and Corrosion on Steel Cladding

Rust is a top concern for steel-based systems like corrugated steel facade or corten steel siding. While corten steel is designed to form a protective rust patina, improper drainage or contact with dissimilar metals can accelerate unwanted corrosion.

- Inspect for pooling water near base plates or joints.

- Clean affected areas with a wire brush and apply a rust-inhibiting primer.

- For long-term protection, consider upgrading to stainless clad aluminum or zinc metal siding in high-moisture zones.

3. Condensation and Moisture Buildup

Metal clad insulation is critical in preventing interior condensation, especially in sheds, garages, or commercial metal clad buildings. Without proper vapor barriers, moisture can accumulate behind metal weatherboard or standing seam siding.

- Ensure your wall assembly includes a breathable housewrap and interior vapor retarder.

- Use aluminum clad pipe insulation on HVAC lines running through metal-clad walls.

- Ventilate attic spaces if you have a metal clad roof—especially colorbond standing seam or pac clad standing seam roof systems.

4. Poor Paint Adhesion or Fading

Paint peeling on metal clad window trim or steel facade panels often stems from inadequate surface prep or UV exposure.

- Sand the surface lightly and clean with TSP (trisodium phosphate).

- Use a high-quality metal primer rated for exterior use.

- Choose factory-finished options like pac clad hwp or pre-painted aluminum clad sheet for better longevity.

5. Dents and Physical Damage

Hail, tools, or accidental impacts can dent exterior corrugated metal siding or vertical standing seam metal siding.

- For minor dents, use auto body filler (like Bondo) only on primed steel plate surfaces—never on bare corten or zinc.

- Replace severely damaged panels with matching materials—e.g., zinc clad dormer panels or 2024 t3 clad sheets.

- Consider thicker gauges (like 1/8 inch steel plate or 3mm aluminium checker plate) in high-risk areas.

6. Electrical and Wiring Issues with Metal Clad Cable

Metal clad electrical wire (often called MC cable) is common in commercial builds, but improper installation can cause grounding faults or code violations.

- Always use listed MC connectors when attaching to junction boxes.

- Never run aluminum clad steel wire through wet locations unless rated for it.

- Confirm local codes—yes, metal clad wire can be used outside and in Pennsylvania commercial buildings, but only if UL-listed and properly supported.

7. Mismatched or Outdated Aesthetics

Tired of your 1990s metal clad house looking industrial? Modern options like copper siding, titanium clad accents, or pac clad column covers can refresh your look.

- Overlay old corrugated panels with new standing seam facade systems.

- Mix materials: pair a corten steel facade with zinc clad roof for contrast.

- Keep in mind corten siding cost averages $7–$12/sq.ft., but offers decades of service with zero painting.

8. Conclusion

Metal clad isn’t just a trend—it’s a smart, sustainable choice for modern construction. By addressing rust, moisture, dents, wiring, and aesthetics head-on, you’ll extend the life of your metal clad building and keep it looking sharp. Whether you’re installing new clad metals or maintaining an existing steel clad house, these fixes ensure performance and curb appeal for years to come.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.